The preparation method and application of a copper -shaped cigarette acid copper micron material

A technology of copper nicotinate and copper coins, applied in the field of micro-catalysis, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

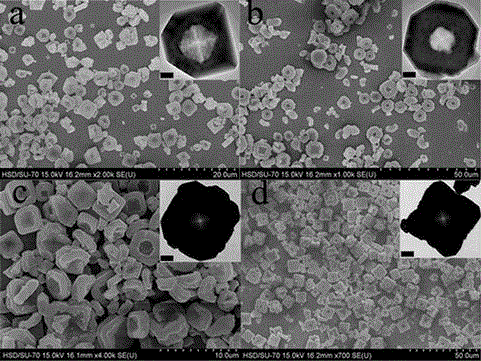

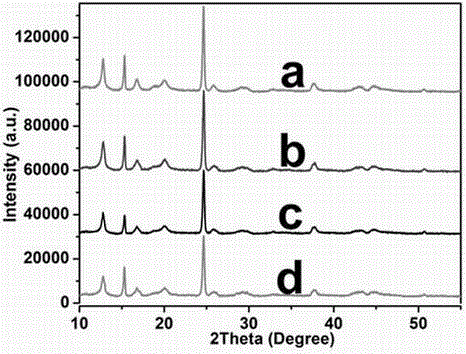

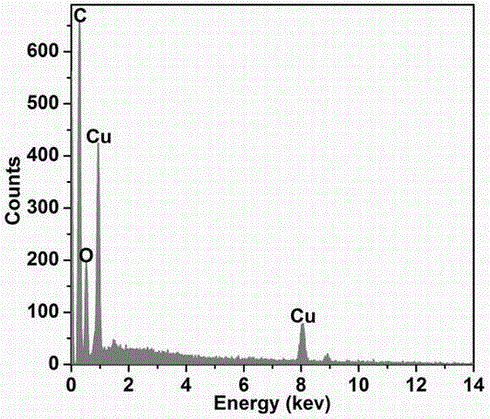

[0026] At room temperature, prepare a 30 mM / L aqueous solution of copper nitrate for use as a stock solution, take 15 mL of copper nitrate aqueous solution and put it into a 100 ml flask, then add 15 mL of ultrapure water, heat to boiling, and place under magnetic stirring Quickly add 30mL 0.2 M / L nicotinic acid to keep boiling, and continue to react for 60 minutes. The color of the solution changes from light blue to blue, accompanied by solid precipitation. Centrifuge the resulting solution at 7000 rpm for 10 minutes , discard the supernatant, remove the unreacted reducing agent nicotinic acid, wash the obtained precipitate with boiling ultrapure water, centrifuge, discard the supernatant, repeat 3 times and dry to obtain octagonal Solid powder of copper nicotinic acid micron material.

Embodiment 2

[0028]At room temperature, prepare a 30 mM / L aqueous solution of copper nitrate for use as a stock solution, take 15 mL of copper nitrate aqueous solution and put it into a 100 ml flask, then add 15 mL of ultrapure water, heat to boiling, and place under magnetic stirring Quickly add 30mL 0.3 M / L nicotinic acid to keep boiling, and continue to react for 60 minutes. The color of the solution changes from light blue to blue, accompanied by solid precipitation. Centrifuge the resulting solution at 6000 rpm for 10 minutes , discard the supernatant, remove the unreacted reducing agent nicotinic acid, wash the obtained precipitate with boiling ultrapure water, centrifuge, discard the supernatant, repeat 3 times and dry to obtain the tetragonal nicotinic acid Solid powder of copper micron material.

Embodiment 3

[0030] Add 0.01 mL of 0.01 M p-nitrophenol solution, 2.5 mL of ultrapure water and 0.1 mL of 0.5 M sodium borohydride ice solution newly prepared into the quartz cuvette, the color of the solution changes from light yellow to bright yellow, According to the ultraviolet spectrum, the characteristic absorption peak of p-nitrophenol is at 400 nm. The mixed solution of copper nicotinic acid micron material with catalyst copper coins was added, and the sample was measured once every 30 s. According to the ultraviolet-visible light absorption spectrum, the absorption peak gradually decreased with the test time until it decreased to a straight line. The degradation rate It can reach more than 99%, and the corresponding solution color becomes colorless, and the characteristic absorption peak of p-aminophenol generated at the same time is at 300 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com