Metal sheet surface strengthening process

A surface strengthening and sheet metal technology, which is applied in the field of sheet metal strengthening, can solve problems such as difficult continuous production, workpiece deformation, and low cleaning efficiency, and achieve the effect of improving tissue performance and surface strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

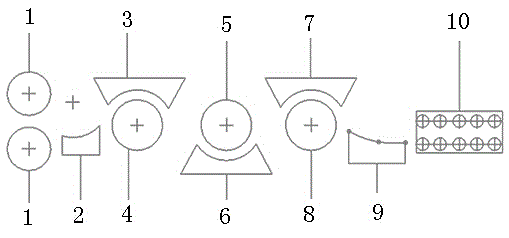

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

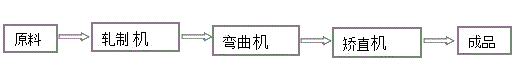

[0013] Such as figure 1 , as shown in 2, a sheet metal surface strengthening process is composed of rolling-bending deformation process, using a rolling mill, a set of bending equipment and a set of straightening equipment.

[0014] On the basis of rolling deformation, through the continuous bending deformation of the metal plate, further plastic deformation occurs on the upper and lower surfaces, so that the grains on the upper and lower surfaces are more refined, and the deformation storage energy (or dislocation density) is greater. , by the Hal1-Petch relation It can be seen that the strength (or hardness) of the upper and lower surface parts will also be greater, so as to achieve the purpose of improving the surface strengthening of the metal sheet. At the same time, combined with the subsequent heat treatment process, the microstructure and propertie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com