Two-stage Stirling cycle refrigerator capable of reaching liquid helium temperature range

A technology of circulating refrigerators and pulse tube refrigerators, applied in the direction of gas cycle refrigerators, refrigerators, refrigeration and liquefaction, etc., can solve the problems of multiple stages, complex structures, and low efficiency of refrigeration systems, and achieve high output efficiency, Effect of small size and reduced input power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

[0033] Example 1

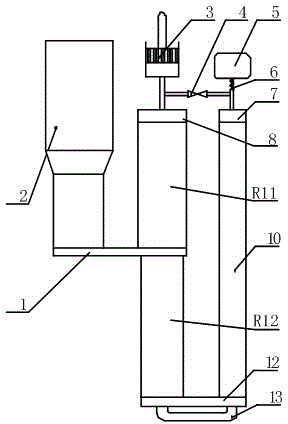

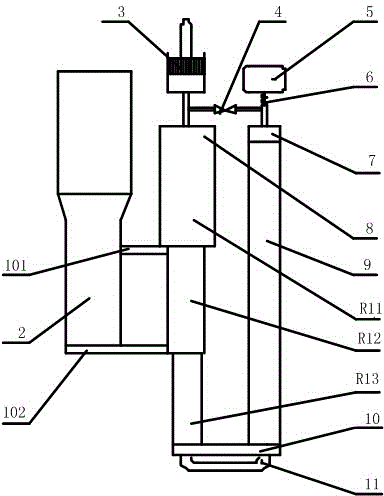

[0034] Such as figure 1 A two-stage Stirling cycle refrigerator that can reach the temperature range of liquid helium is shown, including a single-stage integral linear free-piston Stirling refrigerator 2, a linear compressor 3 and a single-stage Stirling pulse tube refrigerator machine.

[0035] The single-stage Stirling pulse tube refrigerator includes a water cooler (or air cooler) 8 connected in sequence, a first part of the regenerator R11, a second part of the regenerator R12, a cold end heat exchanger 10, and a pulse tube 9. Hot end heat exchanger 7, inertia tube 6 and gas storage 5. The cold head of the second part of the regenerator R12 is connected to the cold head of the pulse tube 9 through the cold end heat exchanger 10, and the second part of the regenerator R12 is connected through a U-shaped tube arranged below the cold end heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com