Prilling tower and process, in particular for producing urea

A granulation tower, urea technology, applied in the direction of urea compound fertilizer, liquid separation into beads and granulation, application, etc., to achieve the effect of improving final quality and production efficiency, eliminating energy consumption, and reducing total cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

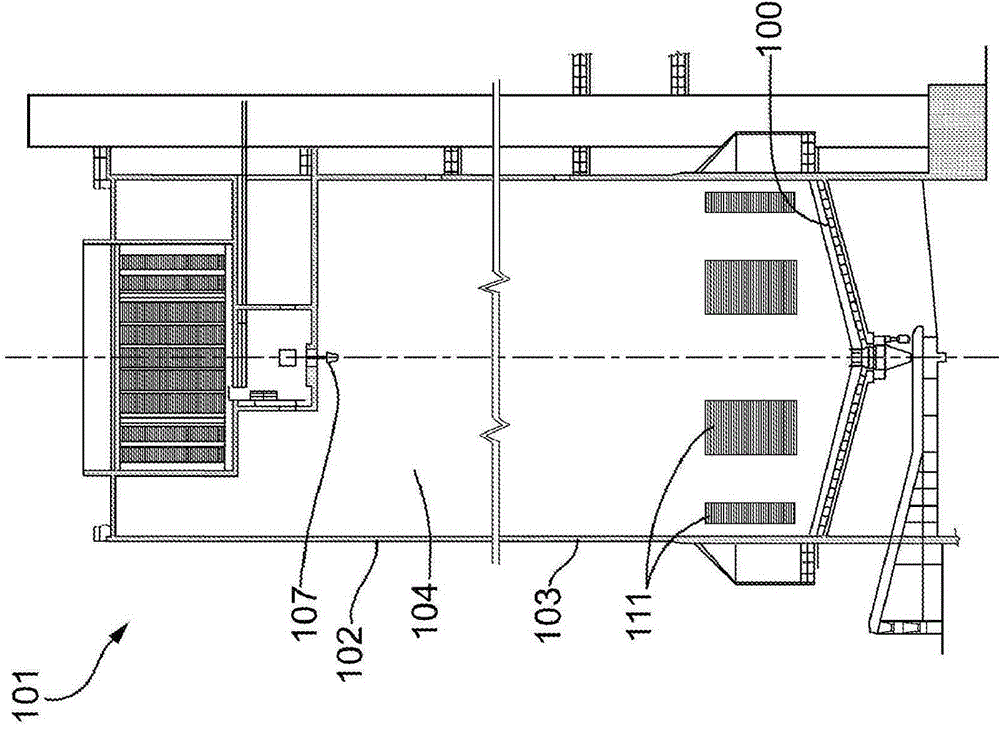

[0027] has been briefly described above figure 1 A prilling tower of the prior art shown in .

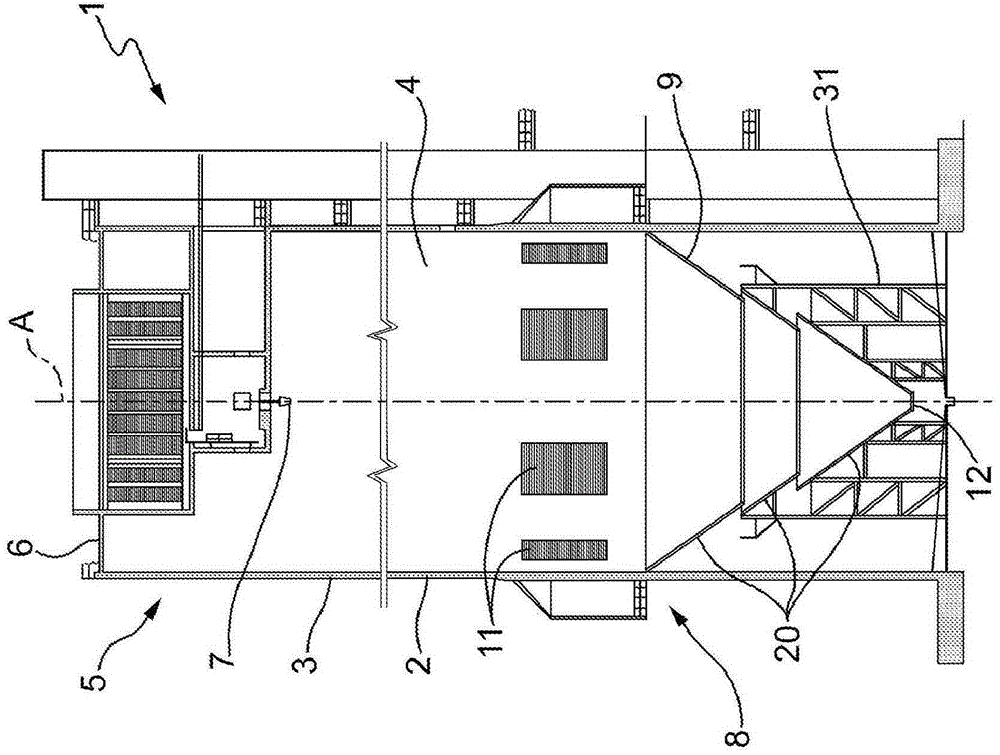

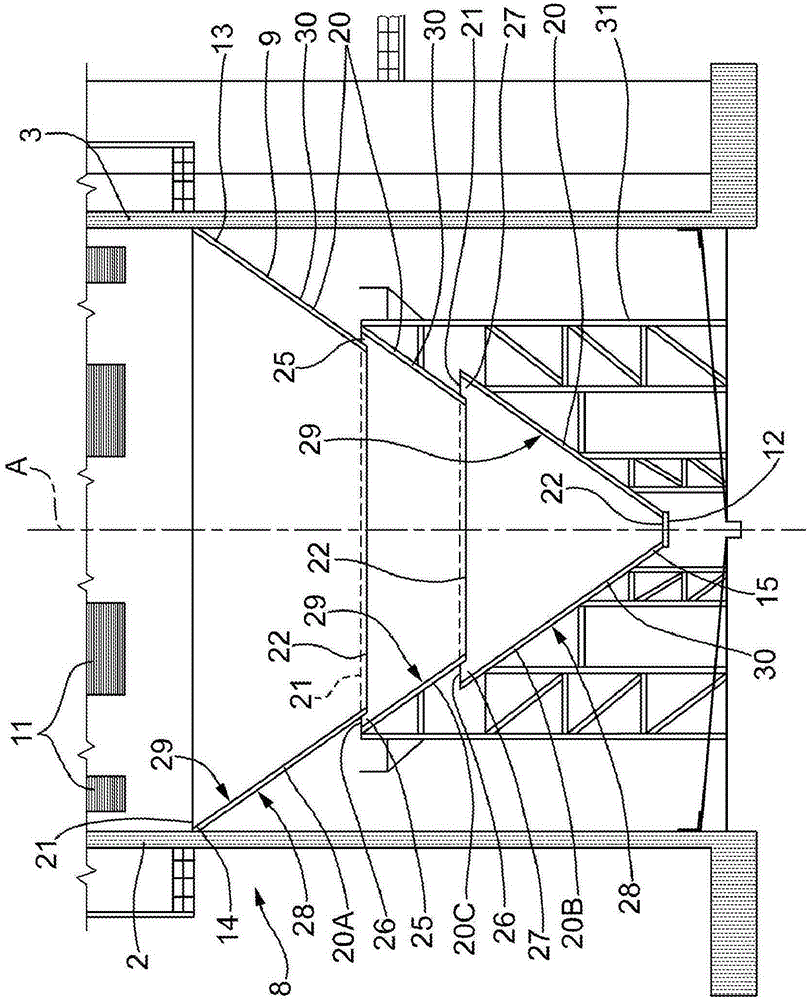

[0028] figure 2 and image 3 A prilling tower 1 according to the invention is shown in .

[0029] The prilling tower 1 of the invention comprises a housing 2 extending along and around a longitudinal vertical axis A;

[0030] The housing 2 extends between an axial top end 5 and an axial bottom end 8 provided with a cover structure 6 connected to the side wall 3 and injectors for supplying the liquid phase (molten urea) in the treatment chamber 4 The bottom end of the device 7 is provided with a transmission structure 9 .

[0031] The side wall 3 is provided with a plurality of adjustable windows 11 , for example provided with adjustable slats of the shutter type, angularly spaced from each other and arranged at the axial bottom end 8 of the housing 2 .

[0032] The conveying structure 9 is arranged below the window 11 and is configured so as to collect the solid material in gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com