Branch pruning robot for overhead high-voltage transmission line live working

A high-voltage transmission line, live operation technology, applied in electric pruning saws, agricultural machinery and implements, agriculture, etc., can solve problems such as robot equipment reports that have not yet been seen, achieve the effect of easy control and operation, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] One, at first introduce the mechanical structure of the present invention.

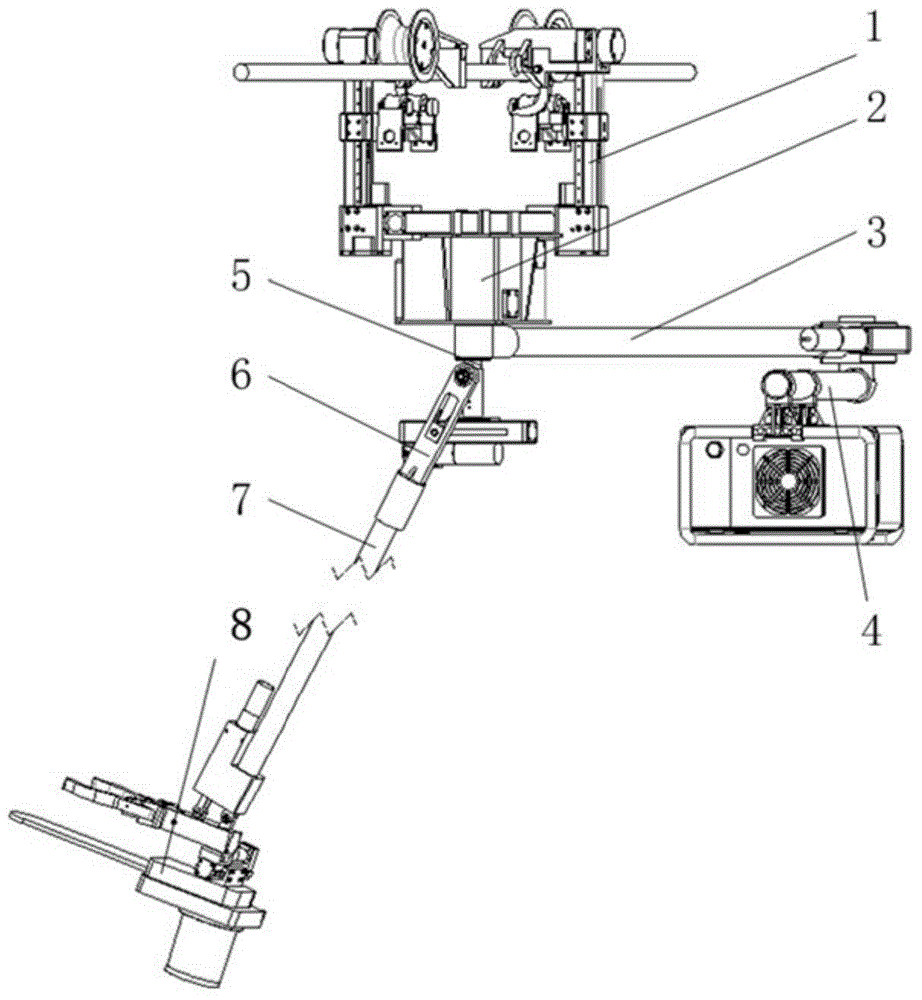

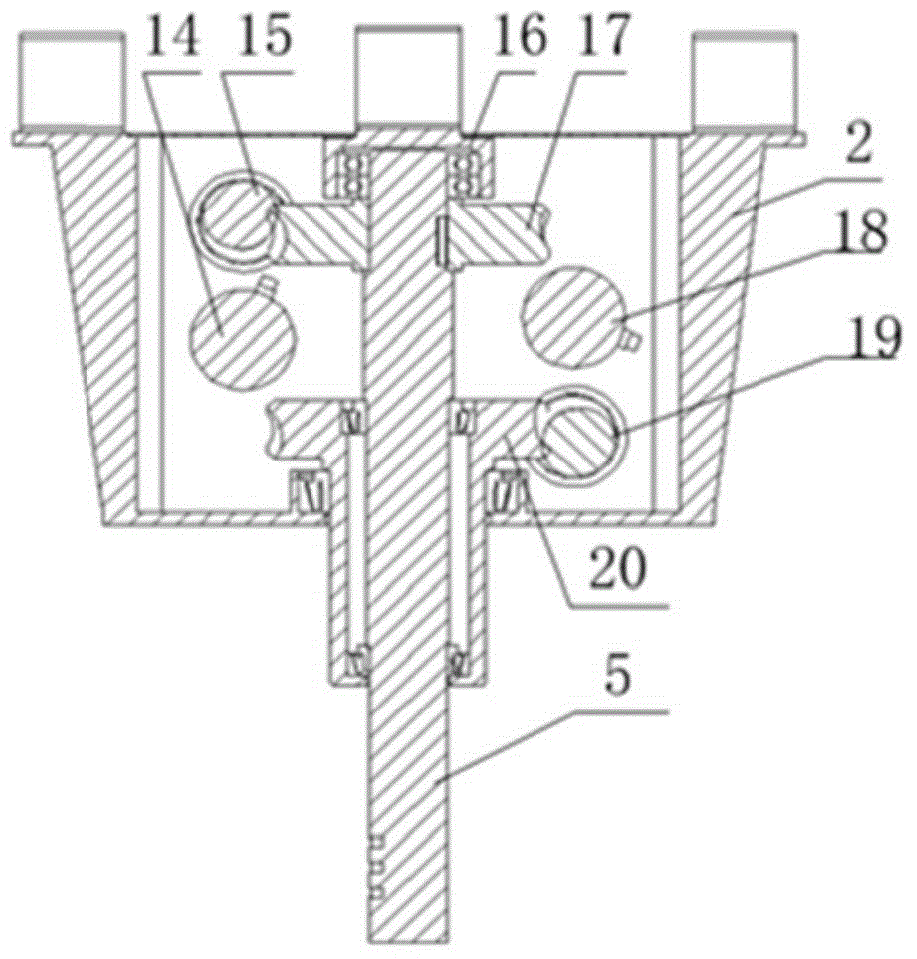

[0034] like figure 1 As shown, the device of the present invention includes five parts: a robot operating platform, a spindle drive box 2, a center of gravity adjustment device, an operating arm swing joint 6 and an end tool 8.

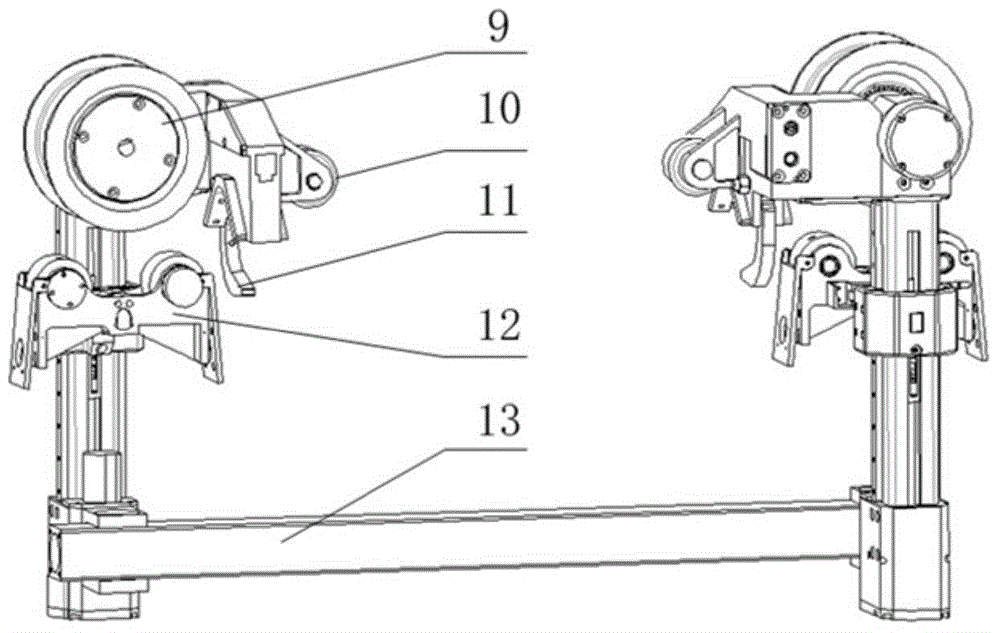

[0035] like figure 2 shown. The robot work platform is used as the mobile carrier of the robot, and a pair of mechanical arms 1 are arranged anti-symmetrically on both sides of the machine body 13 with a fixed distance. The top of the mechanical arm is connected with a walking part 9, a clamping part 11 and an equipotential wheel 10. A pressing wheel that can move up and down is also arranged on the mechanical arm 1. The pressing wheel is arranged on the mechanical arm and connected with the screw nut structure, and the motor Drive the screw nut mechanism, drive the pressing wheel, and perform linear motion in the longitudinal direction of the mechanical arm to com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com