White tea and processing method thereof

A processing method and technology of white tea, applied in tea treatment before extraction, etc., can solve problems such as difficulty in guaranteeing product quality stability, unfavorable large-scale production, and high loss of chlorophyll, achieve a controllable and stable production environment, and overcome leaf color and flower miscellaneous , long-lasting effect of aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

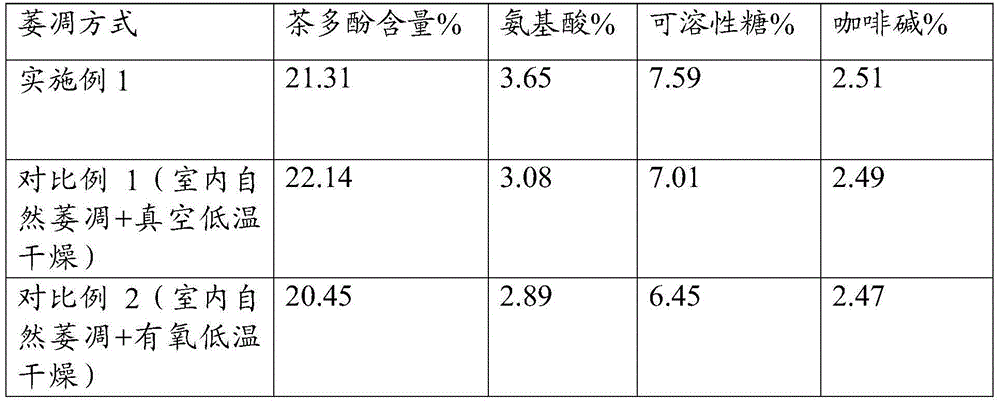

Examples

Embodiment 1

[0031] A processing method for white tea, comprising the steps of:

[0032] (1) Picking fresh leaves: picking fresh leaves of Jinxuan before Qingming in spring, the standard is one bud and two leaves, and the picking time is 8:00-11:00 am on sunny days; pick the leaves lightly, without pressure; within 3 hours after picking Transport back for processing; no pressure should be applied during picking and transporting; fresh leaves should be cooled evenly in a single layer indoors on a ventilated and clean withering mat first, so as to dissipate the accumulated heat in the process of picking and transporting, and avoid red leaves. The leaf temperature can be the same as the indoor temperature;

[0033] (2) Indoor compound withering:

[0034] A: For the first time indoor compound withering of fresh leaves, indoor light withering first (indoor light withering light source can be natural sunlight or artificial light source), the thickness of the spread layer is about 2.2cm, and the...

Embodiment 2

[0041] A processing method for white tea, comprising the steps of:

[0042] (1) Picking fresh leaves: Picking fresh leaves of Jinxuan after Qingming in spring, the standard is one bud and one leaf first unfolding, the picking time is 7:30-10:30 in the morning on sunny days; pick the leaves lightly, without pressure; after picking Transport back for processing within 3 hours; no pressure should be applied during picking and transporting; fresh leaves should be ventilated indoors on a clean withering mat to let them cool down naturally and evenly, so as to dissipate the accumulated heat during picking and transporting, and avoid red leaves from spreading out The thickness is about 0.4cm, and it can be cooled until the leaf temperature is the same as the room temperature;

[0043] (2) Indoor compound withering:

[0044] A: For the first indoor compound withering of fresh leaves, indoor light withering is carried out first, the thickness of the spread layer is about 1.8cm, the in...

Embodiment 3

[0052] A processing method for white tea, comprising the steps of:

[0053] (1) Picking fresh leaves: Picking fresh leaves of Jinxuan before Qingming in spring, the raw material standard used is bud heads, and the picking time is from 7:30 to 10:30 in the morning on sunny days; pick fresh leaves lightly, without pressure; 3 hours after picking Internal transport back to processing; no pressure should be applied during picking and transporting; fresh leaves should be cooled evenly indoors on a ventilated withering mat first, so as to dissipate the accumulated heat during the picking process and avoid red leaves. The thickness of cooling is about 0.7 cm, let it cool until the leaf temperature is the same as the room temperature;

[0054] (2) Indoor compound withering:

[0055] A: For the first indoor compound withering of fresh leaves, indoor light withering first, the thickness of the spread layer is about 1.5cm, the indoor humidity is between 64-75%, the leaf temperature is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com