Preparation method for golden camellia solid beverage

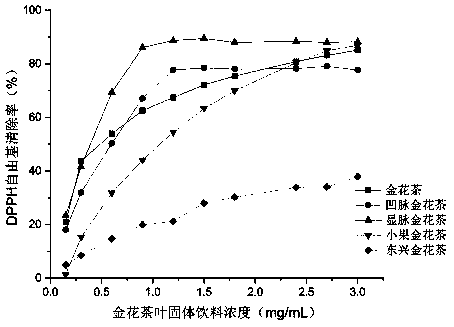

A technology of golden camellia tea and solid beverage, which is applied in tea treatment before extraction, etc. It can solve the problems of high bitterness index of catechins, unfavorable green color of golden camellia tea solid drink, affecting the taste of golden camellia tea solid drink, etc., and achieves good Scavenging effect, good antioxidant activity, effect of improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

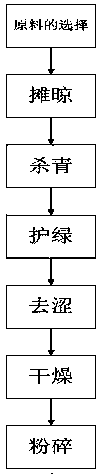

[0057] Embodiment 1 A kind of preparation method of golden camellia tea solid beverage

[0058] Specific steps are as follows:

[0059] (1) Selection of raw materials: Picking free from pests and diseases, free from rot and withering, fresh golden flower tea leaves within one year of growth, removing grass clippings, branches and other impurities;

[0060] (2) Spreading and airing: spread the selected Jinhua tea leaves at 35°C and 60% humidity for 3 hours, with a thickness of about 3 cm, and turn them over every 1 hour;

[0061] (3) Fixing: after drying, use 75°C steam to fix the golden flower tea leaves for 1.5 hours, and immediately cool them to room temperature with cold water after finishing;

[0062] (4) Green protection: Soak the cooled Chrysanthemum japonica leaves in a solution of 0.3% zinc acetate for 1 hour, and rinse with clean water after the end;

[0063] (5) Remove astringency: soak the golden camellia leaves obtained in step (4) with egg white solution with a ...

Embodiment 2

[0066] Embodiment 2 A kind of preparation method of golden camellia tea solid beverage

[0067] Specific steps are as follows:

[0068] (1) Selection of raw materials: Picking free from pests and diseases, free from rot and withering, fresh golden flower tea leaves within one year of growth, removing grass clippings, branches and other impurities;

[0069] (2) Spreading and airing: spread the selected tea leaves of Chrysanthemum japonica at 30°C and 60% humidity for 4 hours, with a thickness of about 4cm, and turn them over every 1 hour;

[0070] (3) Fixing: after drying, blanching the Xianmai Jinhua tea leaves for 1 hour at 80°C, and cooling to room temperature with cold water immediately after finishing;

[0071] (4) Green protection: Soak the cooled Chrysanthemum japonica leaves in a zinc acetate solution with a concentration of 0.2% by mass for 80 minutes, and rinse with clean water after the end;

[0072] (5) Remove astringency: Soak the golden camellia leaves obtained ...

Embodiment 3

[0075] Embodiment 3 A kind of preparation method of golden camellia tea solid beverage

[0076] Specific steps are as follows:

[0077] (1) Selection of raw materials: Picking free from pests and diseases, free from rot and withering, fresh golden flower tea leaves within one year of growth, removing grass clippings, branches and other impurities;

[0078] (2) Spreading and airing: spread and air the selected golden japonica tea leaves at 40°C and 50% humidity for 2 hours, with a thickness of about 3 cm, and turn them over every 1 hour;

[0079] (3) Fixing: After drying, use 85°C steam to fix the golden flower tea leaves for 1 hour, and immediately cool them to room temperature with cold water after finishing;

[0080] (4) Green protection: Soak the cooled Chrysanthemum japonica leaves in a solution of 0.5% zinc acetate for 40 minutes, and rinse with clean water after the end;

[0081] (5) Remove astringency: Soak the golden camellia leaves obtained in step (4) with a soybea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com