Chocolate yoghourt blocks and preparation method thereof

A technology of yogurt block and chocolate, which is applied to milk preparations, bacteria used in food preparation, dairy products, etc., can solve the problems of yoghurt block form and taste, long shelf life, sticky mouth and powder removal, etc., and meet strong market demand Foreground, natural flavor, excellent nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of chocolate yoghurt block, the preparation method comprises the steps of:

[0034] (1) Heat raw milk to 45°C, add sucrose, skimmed milk powder, desalted whey powder, water, arabinogalactan, resistant starch, pectin, stir to dissolve, heat up to 65°C and homogenize to obtain homogeneous liquid;

[0035] (2) Sterilize and cool the homogeneous liquid obtained in step (1) to obtain feed liquid A;

[0036] (3) inoculate the starter to the feed liquid A obtained in step (2), ferment, and cool to obtain fermented milk;

[0037] (4) Pour the fermented milk obtained in step (3) into a mould, and place it in a quick-freezer to obtain a freeze-dried block;

[0038] (5) push the freeze-dried block obtained in step (4) into the freeze-drying bin, freeze-dry and pack, and promptly make the yoghurt block;

[0039] (6) The surface of the yoghurt block obtained in step (5) is coated with chocolate, polished and crystallized to obtain a chocolate yoghurt block. ...

Embodiment 1

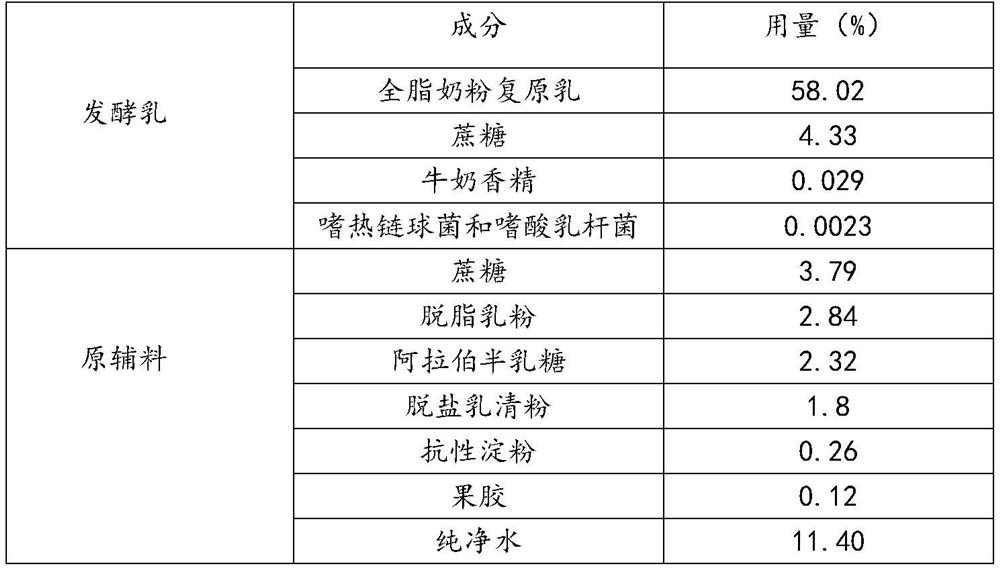

[0073] 1. Raw material formula (see Table 1):

[0074] The raw material formula of table 1 embodiment 1

[0075]

[0076]

[0077] 2. Adopt technical scheme two to prepare yogurt block, the method is as follows:

[0078] (1) Reconstitute the raw material whole milk powder to 1000ml and heat to 45°C, add sucrose, keep stirring for 30min to obtain the base reconstituted milk;

[0079] (2) The base material reconstituted milk obtained in step (1) is subjected to two-stage homogenization, the pressure of the first-stage homogenization is 18 MPa, the pressure of the second-stage homogenization is 5 MPa, and the temperature is 60°C. The homogenized reconstituted milk was sterilized at 90°C for 5 minutes. The sterilized reconstituted milk is cooled to 40°C for use;

[0080] (3) Put the starter (Streptococcus thermophilus and Lactobacillus acidophilus) into the feed liquid obtained in step (2) after cooling at the same time, and stir in the fermenter for 15 minutes, so that t...

Embodiment 2

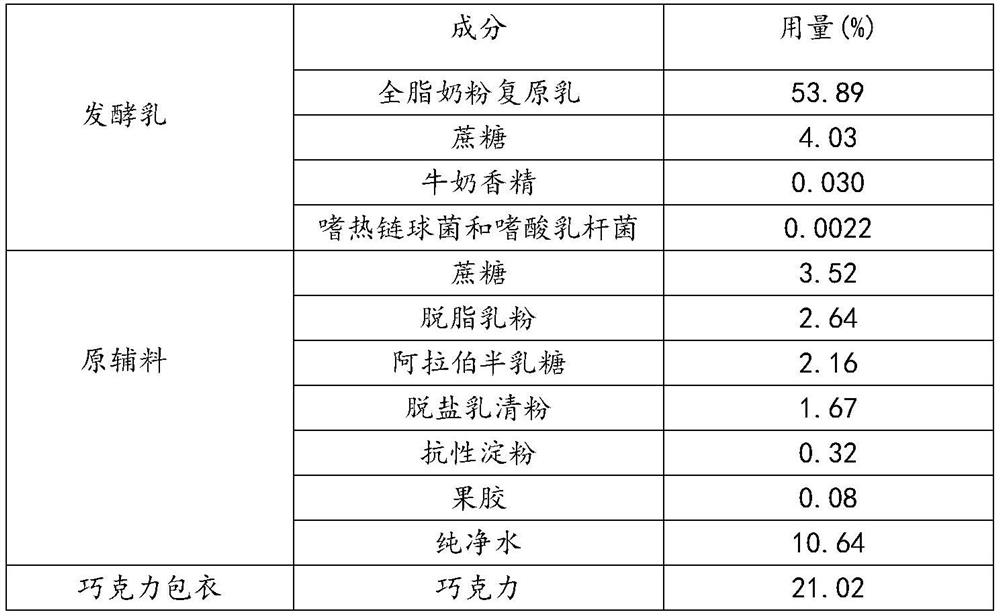

[0087] 1. Raw material formula (see Table 2):

[0088] The raw material formula of table 2 embodiment 2

[0089]

[0090] 2. Adopt the method of technical scheme three to prepare yogurt block, the preparation method is as follows:

[0091] (1) Reconstitute the raw material whole milk powder to 1000ml and heat to 45°C, add sucrose, keep stirring for 30min to obtain the base reconstituted milk;

[0092] (2) The base material reconstituted milk obtained in step (1) is subjected to secondary homogenization, the pressure of the primary homogenization is 19MPa, the pressure of the secondary homogenization is 1MPa, and the temperature is 60°C; the homogenized reconstituted milk is 85°C, sterilized 15min. The sterilized reconstituted milk is cooled to 40°C for use;

[0093] (3) Put the starter (Streptococcus thermophilus and Lactobacillus acidophilus) into the feed liquid obtained in step (2) after cooling at the same time, and stir in the fermenter for 15 minutes, so that the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com