Multi-functional safety protection electric blanket made by polysulfonamide

A safety protection and multi-functional technology, applied in the direction of sleeping blankets, travel blankets, etc., can solve the problems of losing the protection effect of electric blankets on flame retardant and heat insulation, poor heat insulation effect, fusion, etc., and achieve excellent flame retardant and heat insulation effects, good Insulation performance, the effect of avoiding safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

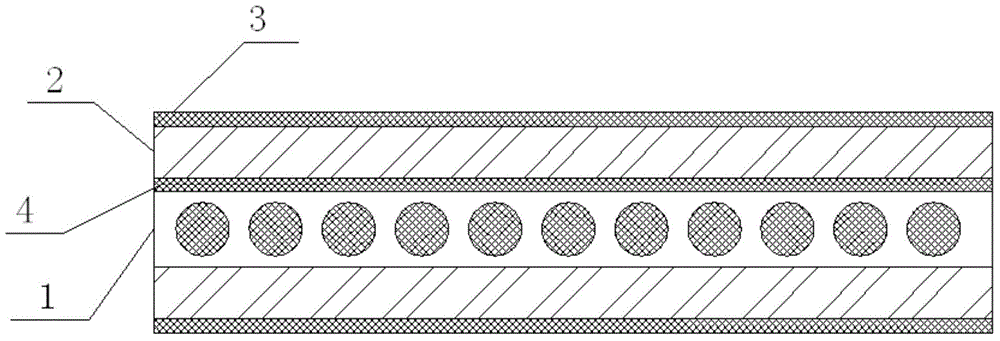

Image

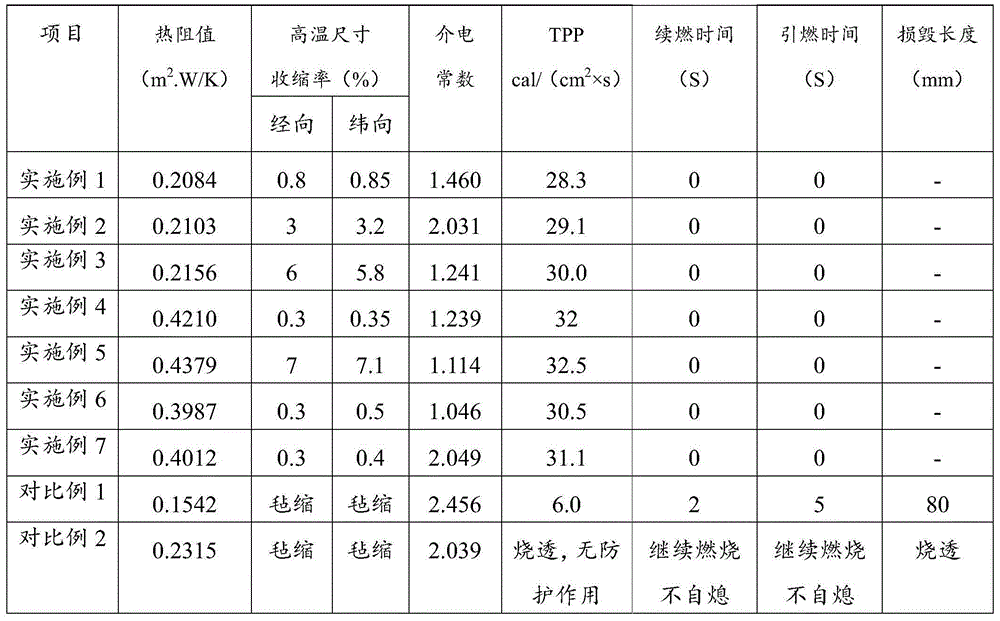

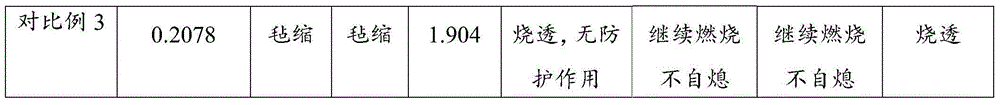

Examples

Embodiment 1

[0037] 180cm×200cm polysulfonamide multifunctional safety protection electric blanket

[0038] 1. Heat insulation layer: According to the existing technology, 5D sulfone fibers are used to make sulfone fibers with a weight of 100g / m 2 Sprayed cotton insulation layer.

[0039] 2. Flame-retardant fabric layer: According to the existing technology, 100% cotton fiber is used for spinning and weaving to make an effective width of 180cm and a weight of 100g / m 2 fabric.

[0040] 3. Spunlace nonwoven fabric layer: According to the existing technology, 100% 2D sulfonamide fiber is used, and processed into an effective width of 180cm and a gram weight of 80g / m by spunlace nonwoven processing method 2 aramid sulfonamide fabric.

[0041] 4. Cut each layer of fabric into a size of 180cm×200cm, and then sew it into the flexible heating element.

[0042] 5. Access to the temperature control system.

Embodiment 2

[0044] 150cm×200cm Aramid 1313 multifunctional safety protection electric blanket

[0045]1. Heat insulation layer: According to the existing technology, 95 parts by weight of 7D aramid fiber 1313 fiber and 5 parts by weight of low-melting point polyester are used to make a grammage of 130g / m 2 shaped cotton.

[0046] 2. Flame-retardant fabric layer: According to the existing technology, 100% viscose fiber is used for spinning and weaving to make an effective width of 150cm and a weight of 90g / m 2 fabric.

[0047] 3. Spunlace nonwoven fabric layer: According to the existing technology, 100% 1.5D polysulfonamide fiber is used, and processed into an effective width of 150cm and a gram weight of 60g / m by spunlace nonwoven processing method 2 aramid sulfonamide fabric.

[0048] 4. Cut each layer of fabric into a size of 150cm×200cm, and then sew it into the flexible heating element.

[0049] 5. Access to the temperature control system.

Embodiment 3

[0051] 150cm×200cm multifunctional safety protection electric blanket

[0052] 1. Heat insulation layer: According to the existing technology, it is made of 95 parts by weight of 9D PPS fiber and 5 parts by weight of low-melting point polyester, with a grammage of 150g / m 2 shaped cotton.

[0053] 2. Flame-retardant fabric layer: According to the existing technology, 50 parts by weight of acrylic fiber and 50 parts by weight of cotton fiber are used for spinning and weaving to make an effective width of 150 cm and a weight of 250 g / m 2 fabric.

[0054] 3. Spunlace nonwoven fabric layer: According to the existing technology, 100% 1.5D aramid fiber is used, and processed into an effective width of 150cm and a gram weight of 60g / m by spunlace nonwoven processing method 2 aramid fabric.

[0055] 4. Cut each layer of fabric into a size of 150cm×200cm, and then sew it into the flexible heating element.

[0056] 5. Access to the temperature control system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Damage length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com