Precracking rebar concrete sample molding die and sample molding method

A technology for reinforced concrete and forming molds, applied in mold auxiliary parts, molds, ceramic molding machines, etc., can solve the problems of thin slices that are not easy to fix, easy to dislocate, etc., and achieve the effect of simple structure, good integrity, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

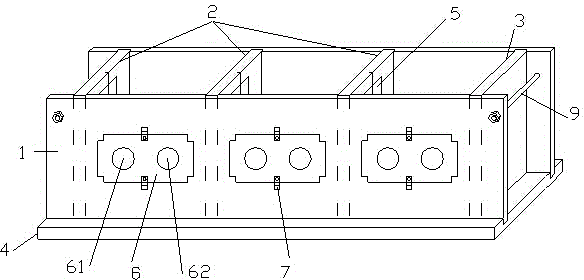

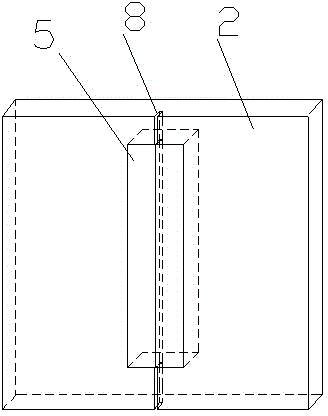

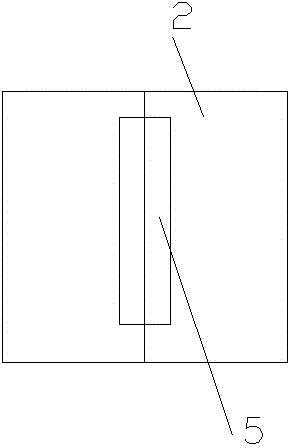

[0034] Such as Figure 1~Figure 5 Shown, a kind of pre-cracked reinforced concrete specimen forming mold embodiment of the present invention comprises bottom plate 4, two side plates 1 and four partitions (also can be two pieces, three pieces or five pieces in other embodiments) more than one piece), three of which are the first partition 2, one is the second partition 3, two side panels 1 are arranged in parallel on both sides of the bottom plate 4, three first partitions 2 and one second partition 3 Inserted in parallel between the two side plates 1 in sequence, the base plate 4, the side plate 1 and the four partitions enclose three cavities for forming co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com