Double-E-corrugated color zero-difference energy-saving reinforcement green package preparation process

A preparation process and differential technology, which is applied in the field of double-E corrugated color non-differential energy-saving enhanced green packaging preparation process, can solve the problems of inconvenience and small quantity, and achieve the effects of reducing production costs, high compressive strength, and reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

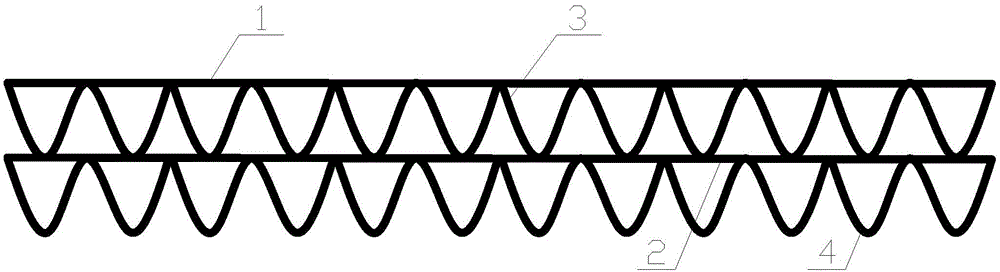

[0030] Such as figure 1 As shown, a kind of double-E corrugated color non-differential energy-saving enhanced green packaging, including the first composite layer 1 and the second composite layer 2, between the first composite layer 1 and the second composite layer 2 is provided with the second composite layer of the same height A corrugated reinforcing layer 3, the upper and lower vertices of the first corrugated reinforcing layer 3 are respectively bonded together with the first composite layer 1 and the second composite layer 2 through an adhesive, and the other side of the second composite layer 2 is bonded with The second wave-shaped reinforcing layer 4 of the same height is continuous to form a double E corrugated structure, and the corrugated shape has very good supporting strength;

[0031] The adhesive is made of the following components in parts by weight: 20 parts of vinyl acetate, 5 parts of hydrogen-containing silicone oil, 20 parts of toluene, 30 parts of polyest...

Embodiment 2

[0037] A preparation process for double-E corrugated color non-differential energy-saving enhanced green packaging, comprising the following steps:

[0038] A. Utilize the corrugating machine to produce corrugated cardboard from base paper, and send the cardboard produced by the corrugating machine to the first forming unit and the second forming unit respectively;

[0039] B. The first molding unit and the second molding unit respectively mold corrugated cardboard to make two groups of E-corrugated cardboard;

[0040] C. Laminate the E-flute cardboard prepared on the second forming unit with the E-corrugated cardboard on the first forming unit through the steering conveying device, and send it to the cutting and compounding unit;

[0041] D. Combining two sets of E-flute cardboards together through the cutting and compounding unit to form double E-flute cardboards. The double E-flute cardboards are folded by the folding machine, and the folded cardboards are sent to the CNC d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com