Industrial vehicle and traveling mechanism thereof

A technology for industrial vehicles and running mechanisms, applied to vehicle components, wheels, motor vehicles, etc., can solve the problems of poor environmental adaptability and single walking mode, and achieve the effect of simple structure and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

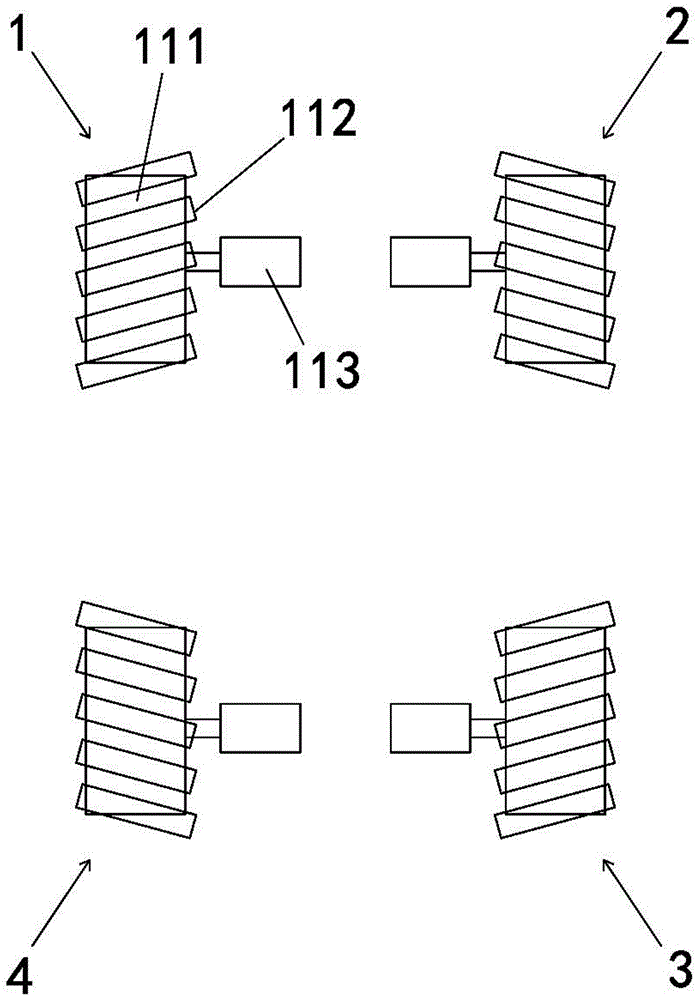

[0026] Embodiment 1: An industrial vehicle running mechanism, including at least four wheel sets, the closed-loop connection line of the four wheel sets is a quadrangle, and the quadrangle is a rectangle in this embodiment; figure 1 As shown, the four wheel sets are respectively the first wheel set 11, the second wheel set 12, the third wheel set 13, and the fourth wheel set 14; the first wheel set 11 and the third wheel set 13 are diagonally distributed, The second wheel set 12 and the fourth wheel set 14 are arranged diagonally.

[0027] The four wheel sets have the same structure, and all include a driving wheel 111, a plurality of driven wheels 112 that can be driven to rotate by the friction force generated between the driving wheel 111 and distributed along the circumferential direction of the driving wheel 111, and the driven wheels 112 are rotatably connected to Driving wheel 111; the walking medium is generally the ground.

[0028] The axis of the driven wheel 112 of...

Embodiment 2

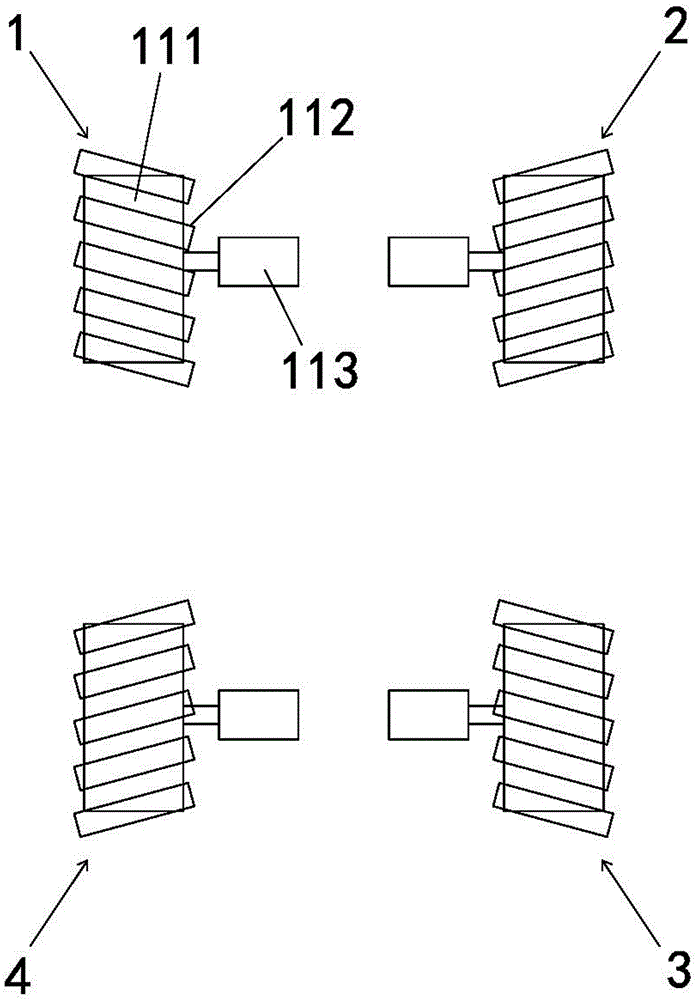

[0037] Embodiment 2: The difference with Embodiment 1 is that, as figure 2 As shown, with any sideline of the quadrilateral as the boundary line, the side close to the center of the industrial vehicle is the inner side, and the other side is the outer side; The inner side; the axis of the driven wheel 112 of the first wheel set 11 can be parallel or coincident with the axis of the driven wheel 112 of the third wheel set 13; the axis of the driven wheel 112 of the second wheel set 12 can be parallel or coincident with the fourth The axis of the driven wheel 112 of the wheel set 14.

Embodiment 3

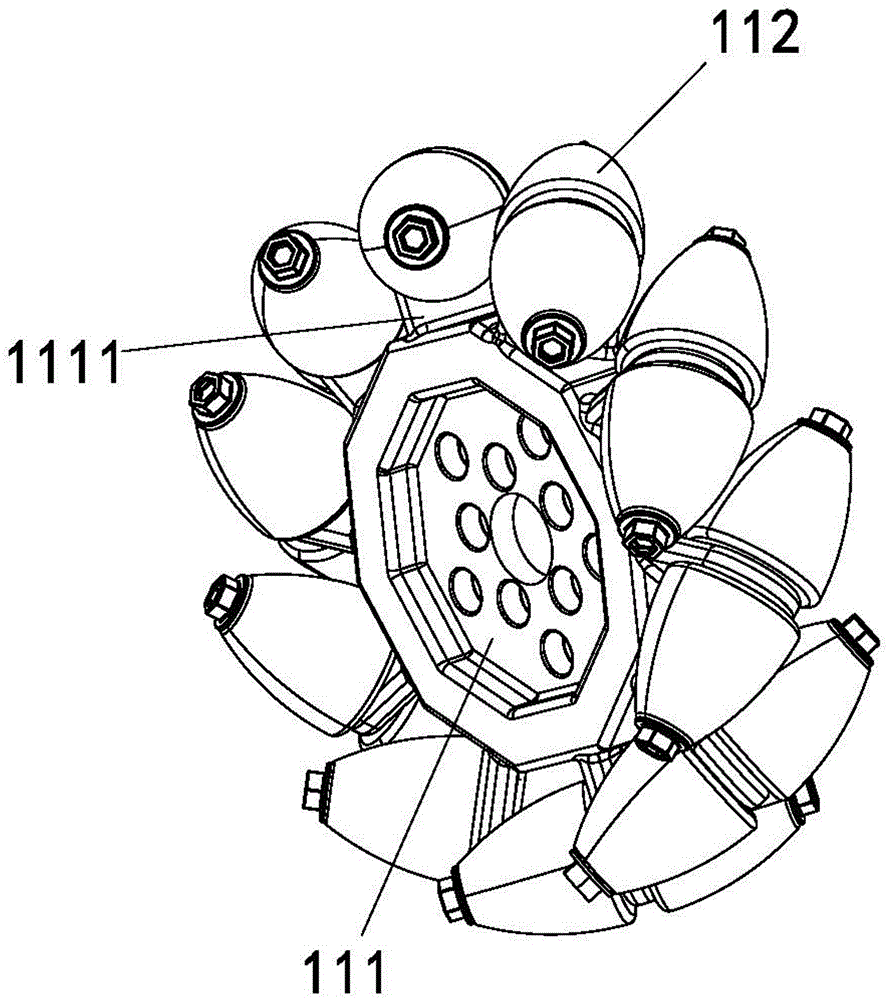

[0038] Embodiment 3: a kind of wheel group structure that is applicable to industrial vehicle running gear, as image 3 As shown, it includes a driving wheel 111 and a driven wheel 112; several hinged seats 1111 are arranged along the circumferential surface of the driving wheel 111, and the driven wheel 112 is rotatably connected to the hinged seats 1111, and the axis of the driven wheel 112 is inclined to the axis of the driving wheel 111 ; In order to improve the effective contact between the driven wheel 112 and the ground in various walking modes, the driven wheel 112 has a tapered outer diameter gradually decreasing along the direction from the middle to both ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com