Belt joint automatic-avoiding device of AR film coating roller coater

A technology of belt joint and AR coating, applied in the field of automatic control avoidance device for belt joint of AR coating roller coating machine, to achieve the effect of simple and reliable operation, improvement of product quality and pass rate, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in conjunction with accompanying drawing and specific embodiment;

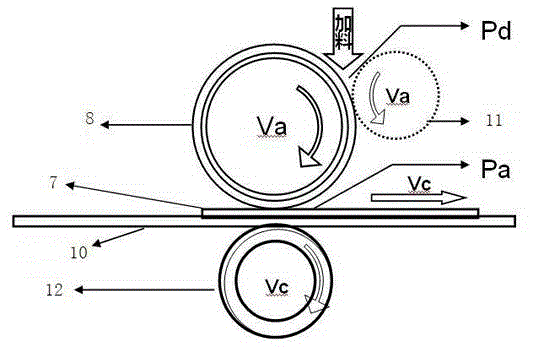

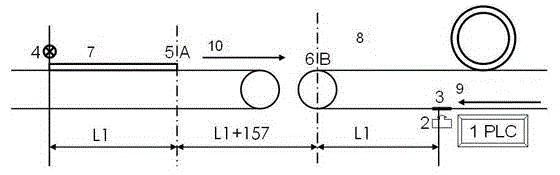

[0019] Such as figure 1Shown, a kind of AR coating roller coating machine belt joint automatic avoidance device, the roller coating machine belt 9 of AR coating roller coating machine and glass conveyor belt 10 are arranged side by side; The delivery direction and the delivery speed of the coater belt 9 are the same, and the delivery speed is V; the bottom of the roller coater belt 9 is provided with a non-contact proximity switch 2 for detecting the belt joint; connect the top of the pulley to the roller coater The tangent point of the belt is taken as the reference point B6, and the distance between the reference point B6 and the non-contact proximity switch 2 is set as L1 according to the glass length, and the distance traveled by the belt joint to reach the reference point through the non-contact proximity switch Set as L2, the length of L2 is equal to the glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com