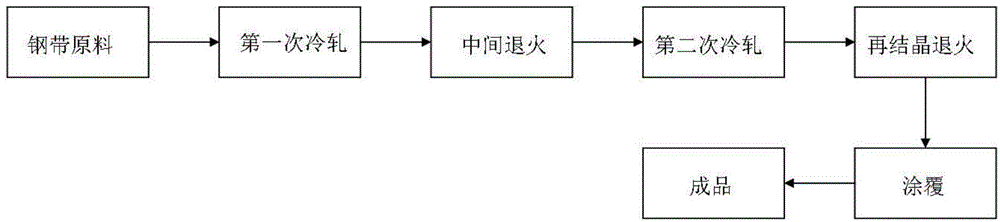

Manufacturing process of ultra-thin oriented silicon steel strip

A technology of oriented silicon steel and manufacturing process, which is applied in the field of preparation of silicon steel thin strips, can solve problems such as poor texture orientation, large cold rolling deformation, and difficult product rate, so as to reduce equipment load, facilitate cold rolling deformation, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A manufacturing process of an ultra-thin oriented silicon steel strip described in this embodiment comprises the following steps:

[0034] (1) The first cold rolling: use 0.3mm thick ordinary oriented silicon steel as the raw material of the steel strip, and the cutting width is 200mm. At room temperature, the first cold rolling is carried out, and the rolling deformation rate is 88%. 3 to 7 passes, and the cooling liquid known in the art is used in the cold rolling process;

[0035] (2) Intermediate annealing: Continuous intermediate annealing is carried out under a hydrogen protective atmosphere, the annealing temperature is 750°C, and the annealing speed is 2 m / min to form a recrystallized structure;

[0036] (3) The second cold rolling: at room temperature, under 40% deformation rate, carry out the second cold rolling, the cold rolling pass is 3 to 7 passes, and the final rolling thickness is 0.02mm;

[0037] (4) Recrystallization annealing: Under the hydrogen-nitr...

Embodiment 2

[0041] A manufacturing process of an ultra-thin oriented silicon steel strip described in this embodiment comprises the following steps:

[0042] (1) The first cold rolling: use 0.2mm thick ordinary oriented silicon steel as the raw material of the steel strip, and the cutting width is 200mm. At room temperature, the first cold rolling is carried out, and the rolling deformation rate is 50%. 3 to 7 passes, and the cooling liquid known in the art is used in the cold rolling process;

[0043] (2) Intermediate annealing: Continuous intermediate annealing is carried out under a hydrogen protective atmosphere, the annealing temperature is 1150°C, and the annealing speed is 20 m / min to form a recrystallized structure;

[0044] (3) The second cold rolling: at room temperature, under 80% deformation rate, carry out the second cold rolling, the cold rolling pass is 3~7 passes, and the final rolling thickness is 0.02mm;

[0045] (4) Recrystallization annealing: Under hydrogen-nitrogen ...

Embodiment 3

[0049] A manufacturing process of an ultra-thin oriented silicon steel strip described in this embodiment comprises the following steps:

[0050] (1) The first cold rolling: using 0.25mm thick ordinary oriented silicon steel as the steel strip raw material, the cutting width is 200mm, at room temperature, the first cold rolling is carried out, the rolling deformation rate is 80%, the cold rolling pass 3 to 7 passes, and the cooling liquid known in the art is used in the cold rolling process;

[0051] (2) Intermediate annealing: Under the hydrogen-nitrogen protective atmosphere, continuous intermediate annealing is carried out, the annealing temperature is 950°C, and the annealing speed is 11 m / min to form a recrystallized structure;

[0052] (3) The second cold rolling: at room temperature, under 60% deformation rate, carry out the second cold rolling, the cold rolling pass is 3-7 passes, and the final rolling thickness is 0.02mm;

[0053] (4) Recrystallization annealing: Und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Magnetic induction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com