Orthogonal-diagonal U-shaped steel and concrete composite open-web floor and manufacturing method

A technology of orthogonally inclined and empty-belly floors, which is applied to floors, building components, buildings, etc., can solve the problems of reduced stiffness and comfort, uneven force, and waste of materials, so as to improve structural stiffness and comfort, The effect of reducing the thickness of the floor and saving building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

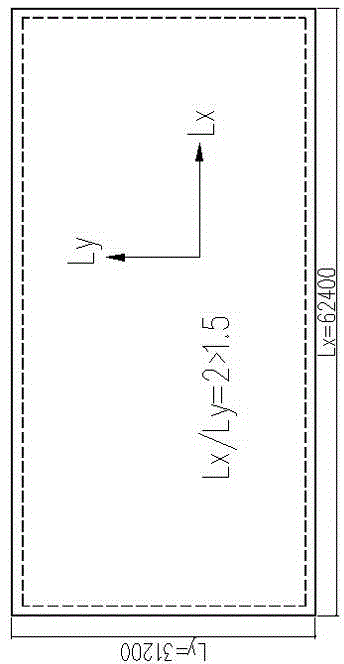

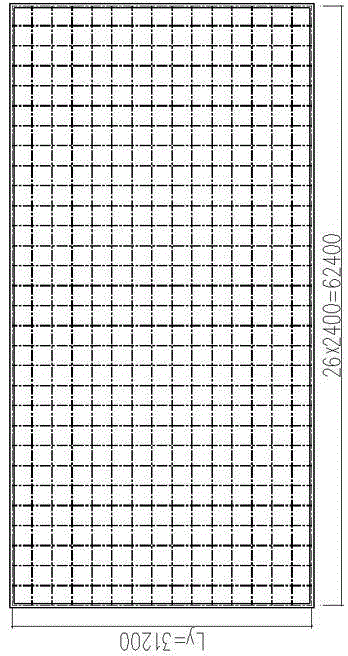

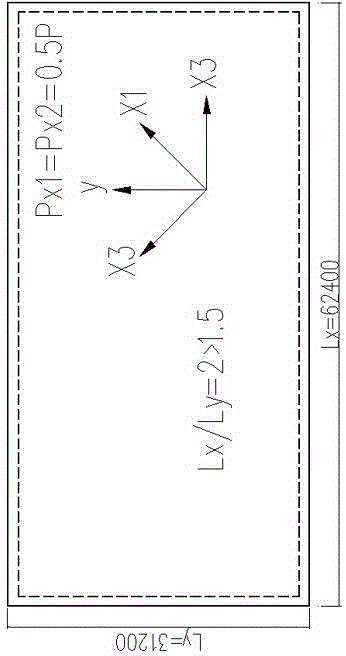

[0039] Embodiment 1, U-shaped steel and concrete combined empty-belt floor is placed orthogonally and obliquely. The perimeter of the building floor is an isosceles triangular grid, and the middle is along the perimeter of 45 0 The included angle is a square fasting grid; the dimension a of the right-angled side of the surrounding isosceles triangle and the length a1 of the hypotenuse of the isosceles triangle are a=a1×sin45 0 relationship, that is, after the peripheral grid a1 is determined, the internal edge 45 0The size of the directional square grid a is determined; the building floor is composed of the lower chord and the upper chord connected by reinforced concrete shear keys, and the lower chord is made of U-shaped steel members that also serve as bottom formwork, side formwork, and stressed steel plates, and steel bars in the grooves of U-shaped steel members Composed of concrete layers; the building floor is the long side (L x ) with the short side (L y ie span) rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com