Multifunctional Drilling String Joints

A pipe string joint and multi-functional technology, applied in the direction of drill pipe, drilling equipment, drill pipe, etc., can solve the problems of time-consuming and laborious connection and unloading of the drill string, slow thread connection speed, weak sealing ability, etc., and achieve fast tripping speed , Fast loading and unloading speed, strong sealing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in combination with specific embodiments and accompanying drawings, and the advantages and characteristics of the present invention will become clearer along with the description.

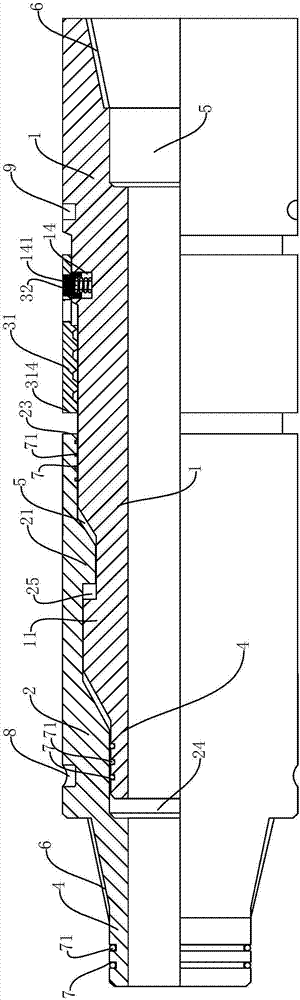

[0030] like figure 1 As shown, it is a cross-sectional view of the multifunctional drilling string joint of the present invention, the joint includes: an upper joint 1, a lower joint 2, and a fixing device.

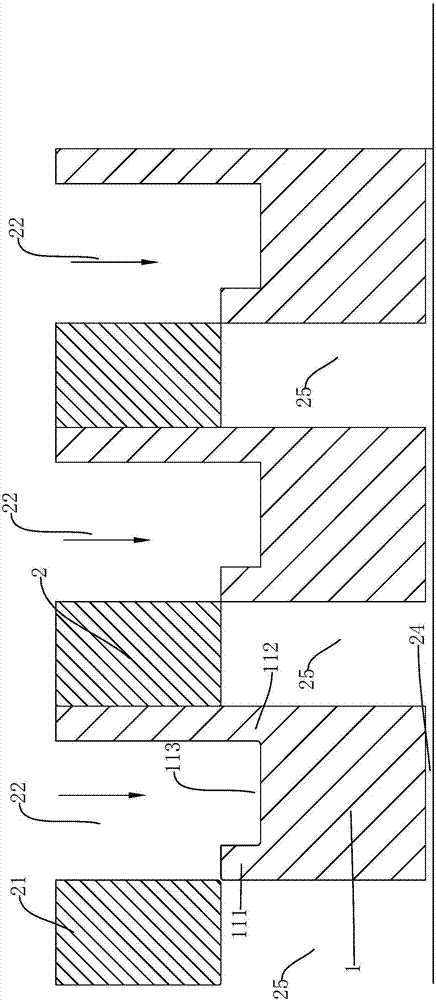

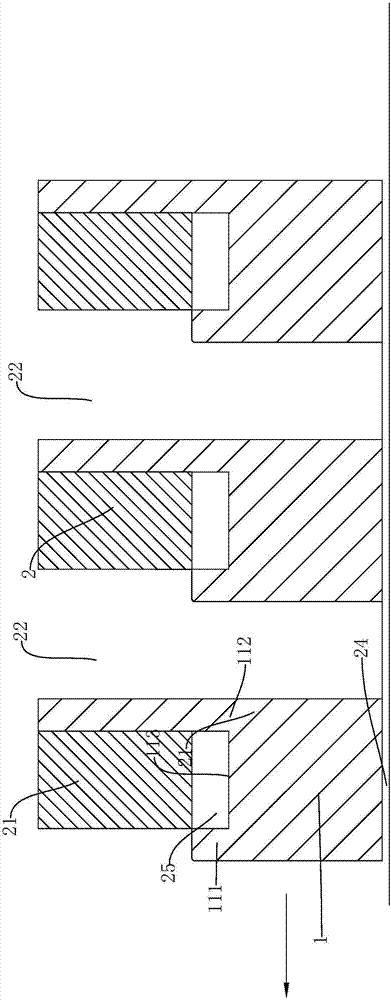

[0031] Among them, such as Figure 2 to Figure 6 As shown, the outer wall of the upper joint 1 has several joint protrusions 11. In the present invention, the number of joint protrusions 11 is 3 and evenly distributed on the inner wall circumference of the upper joint 1. Each joint protrusion 11 is Occupying 75° of the circumference, the joint protrusion 11 also includes an anti-reverse protrusion 111 and a load key 112, and a card slot 113 is formed between the anti-reverse protrusion 111 and the load key 112; The reverse protrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com