Oil reservoir collector

A technology for oil reservoirs and oil wells, applied in the field of oil reservoir collectors, can solve the problems of oil wells unable to maintain normal production, flow difficulties in low-temperature areas, and loss of fluidity, etc., to improve the effect of viscosity reduction, facilitate collection, and ensure efficiency and effectiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

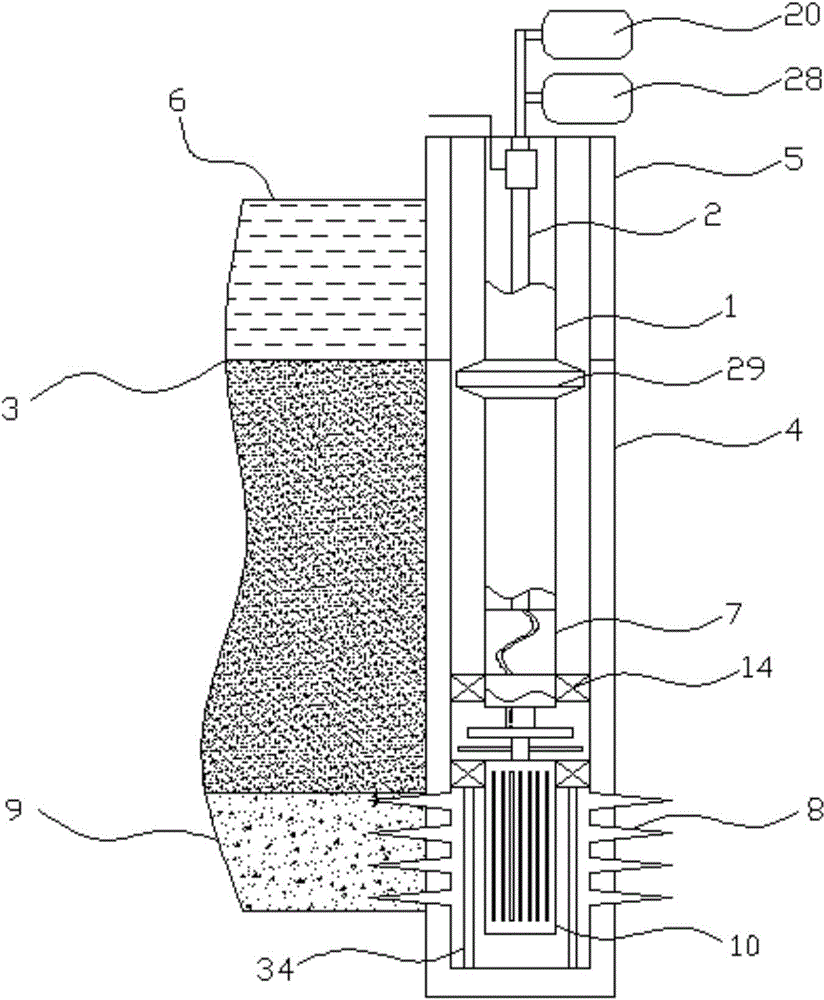

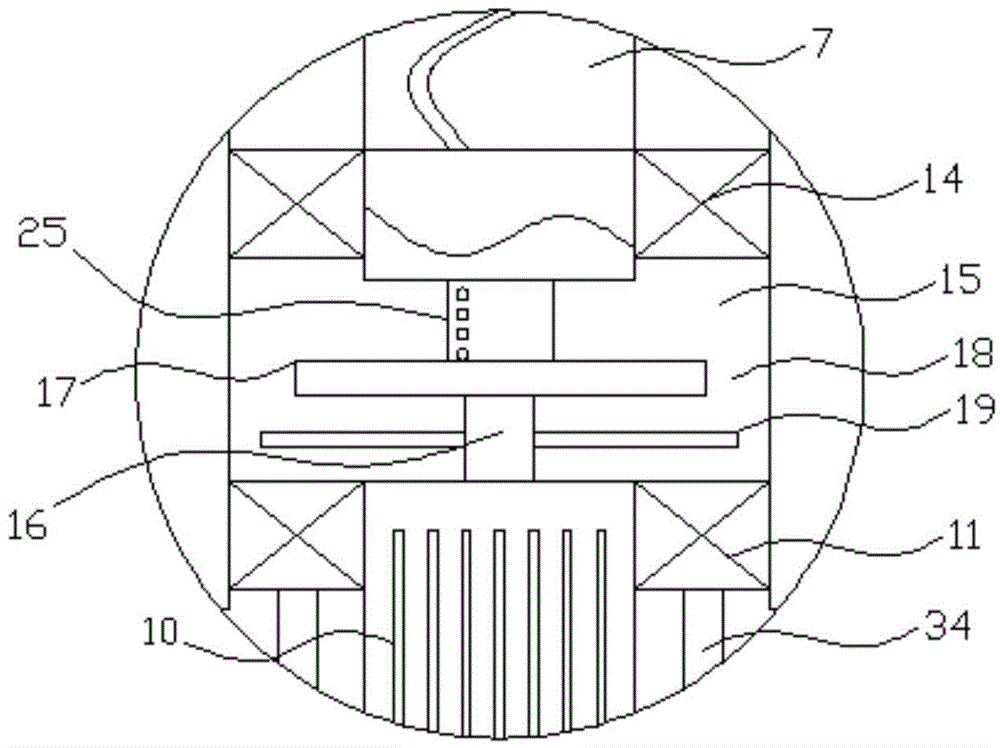

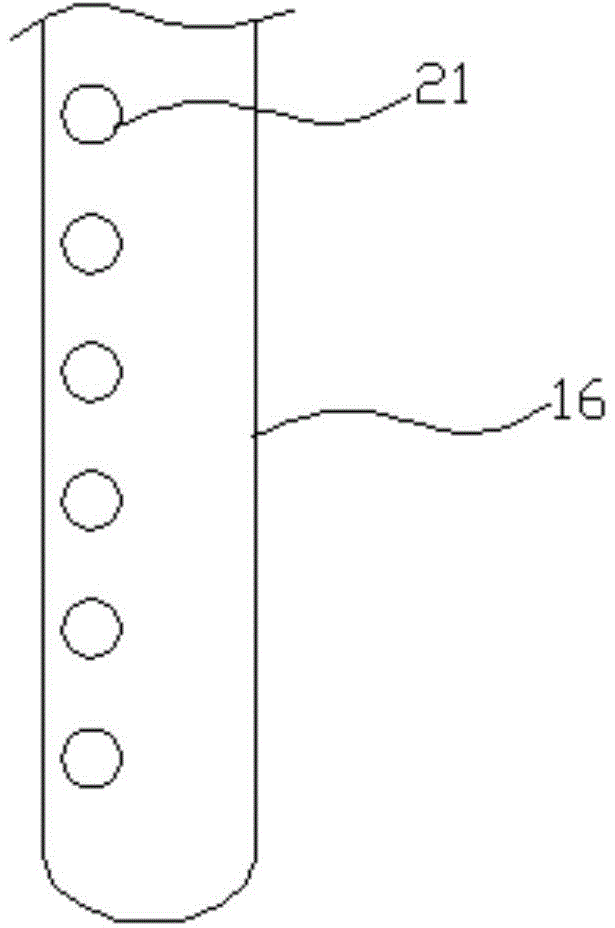

[0026] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 In the shown embodiment, an oil reservoir recovery device comprises a main tubing 1, a hollow sucker rod 2 with an open upper end, and an oil wellbore 4 extending below the seabed mud line 3, and the oil wellbore is provided with There is a riser 5 with an inner cavity, the top of the riser protrudes from the sea surface 6, the wall of the oil wellbore and the pipe wall of the riser are sealed and connected, the main oil pipe passes through the inner cavity of the riser, and the lower end of the main oil pipe extends In the oil wellbore, the main oil pipe is provided with a screw pump 7, the upper end of the main working screw of the screw pump is connected with the lower end of the sucker rod, and the screw pump is located at the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com