Multiplex radial plunger pump

A radial column and piston pump technology, applied in the field of plunger pumps, can solve the problems such as the inability to use the distribution shaft and the multiple pressure oil outlets of the plunger, the difficulty of adjusting the arbitrary displacement, the difficulty of processing, etc., and achieve assembly and maintenance. The effect of convenience, reducing production efficiency and improving mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given hereby, and the details are as follows:

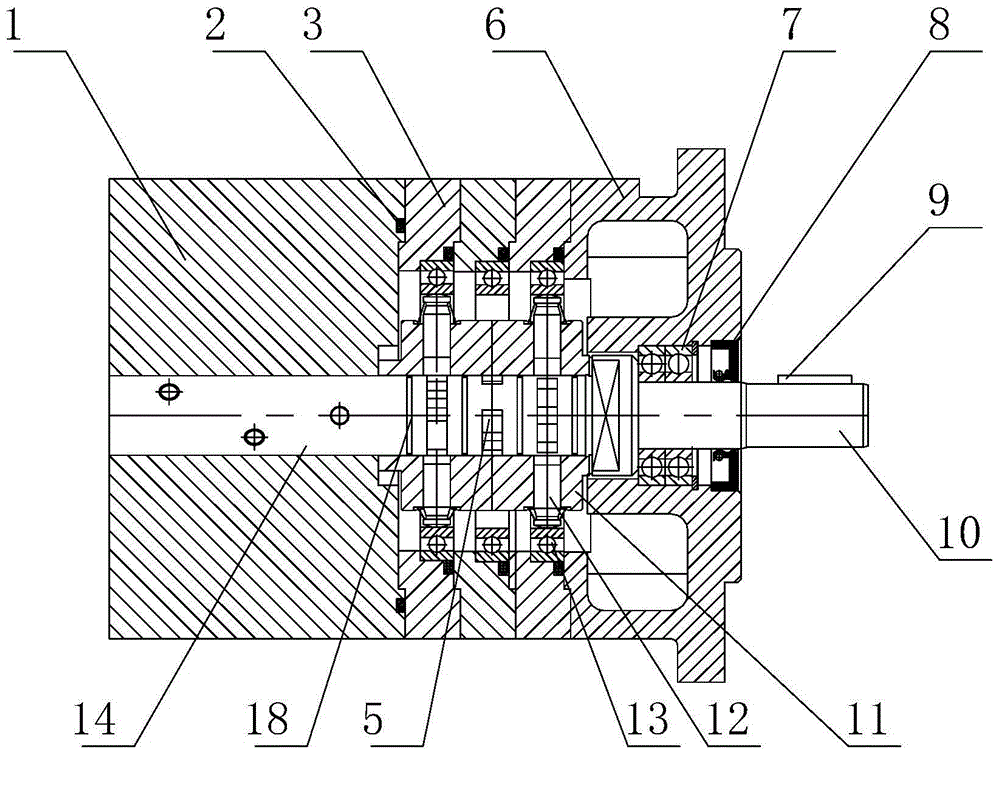

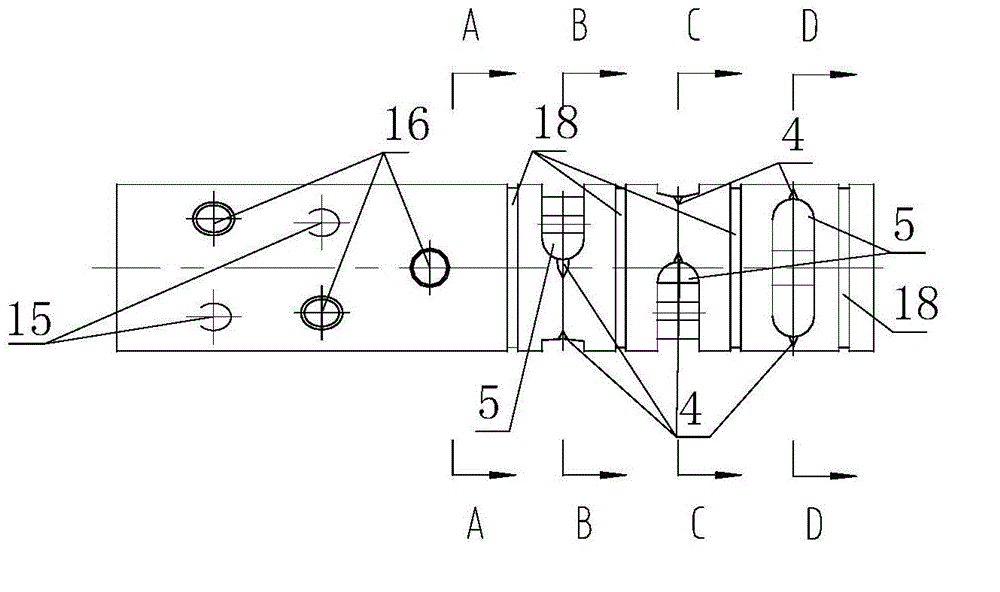

[0020] Such as Figure 1-6 as shown,

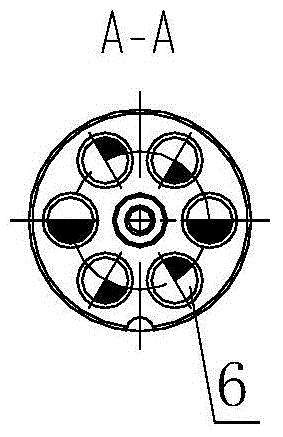

[0021] A multi-connected radial piston pump, including a pump base 1, the center of the pump base is provided with a flow distribution shaft installation hole, and a plurality of sub-pump bodies 3 are connected in series on one side in the axial direction of the pump base, and the eccentricity of each sub-pump body There are different eccentric distances between the holes, and a pump head 6 is connected in series on the right side of the sub-pump body, between each sub-pump body 3, between the sub-pump body 3 and the pump seat 1, and the pump head 6 are sealed by a sealing ring 2;

[0022] A distribution shaft 14 is also worn in the pump seat. The distribution shaft includes a shaft body, which is provided with three pairs of oil inlets 15 and oil ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com