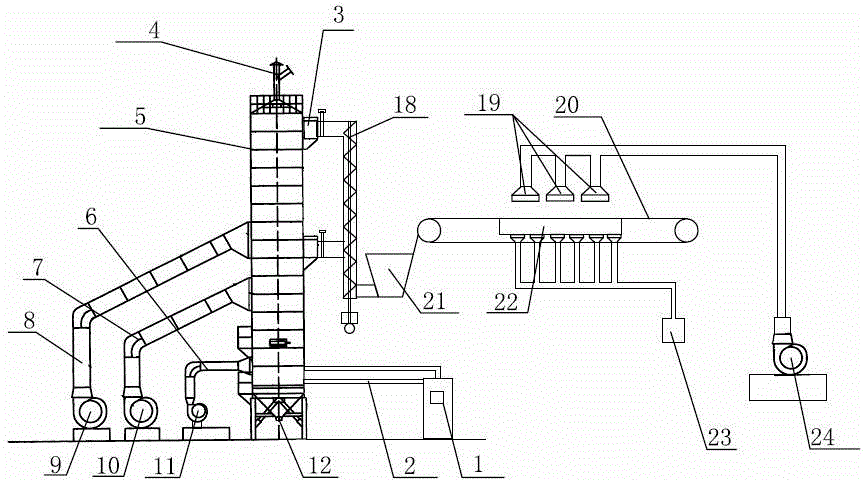

Grain drying machine with synchronous dust-removing function

A technology for grain dryers and drying chambers, which is applied in the direction of dryers, dryers, dryer combinations, etc., which can solve the problems of waste, large energy loss, and large energy consumption, and achieve high drying efficiency and high drying efficiency. Good effect, thorough and efficient drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

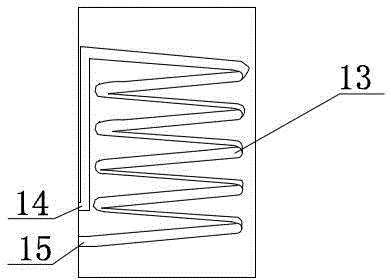

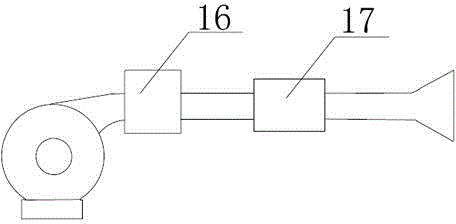

[0021] The synchronous dedusting grain dryer of the present embodiment is as figure 1 and figure 2 As shown, it includes a conveyor belt, three hot air nozzles 19, a drying bin 5, four hot air blowers, hot air pipes, coil pipes 13 and a boiler 1. The surface of the conveyor belt 20 is grid-like. The 4th hot air blower 24 is communicated with the hot blast nozzle 19 by the 4th hot blast pipe, and the hot blast nozzle 19 is positioned at the conveyor belt 20 tops, and the conveyor belt 20 below is provided with dust box 22, and dust box 22 is communicated with vacuum pump 23 by pipeline, and conveyor belt 20 one end is provided with There is a collecting hopper 21, and the collecting hopper 21 is connected with an auger 18; the drying bin 5 is provided with a grain inlet 3 and a grain outlet 12, and there are three hot air blowers, which are respectively the first hot air blower 11, the second hot air blower 10 and the second hot air blower. Three hot air blowers 9, three hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com