CPU (central processing unit) integrated heating pipe radiator structure

A technology that integrates heat pipes and radiators, applied in the fields of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of low contact surface between heat pipes and heat sources, limited cooling performance of radiators, and low return efficiency of heat pipes, etc. Achieve the effect of being suitable for large-scale promotion, reducing the possibility of capillary limit occurrence, and increasing the difficulty of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A specific embodiment of the present invention will be described below in conjunction with the accompanying drawings.

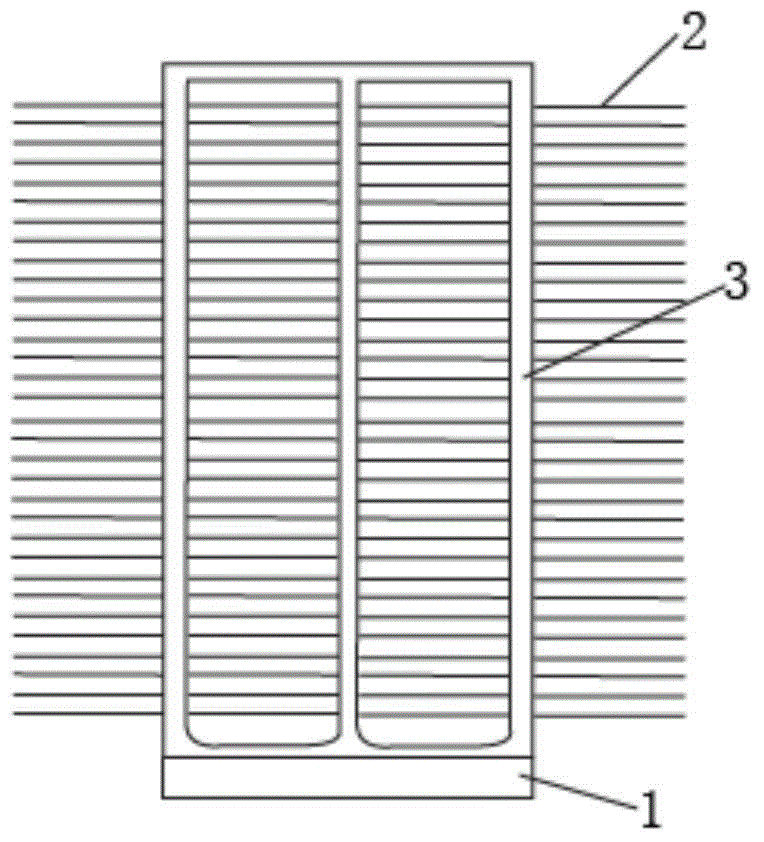

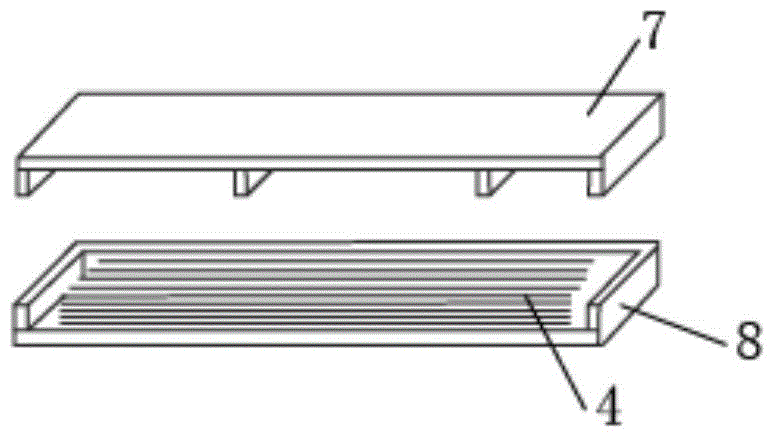

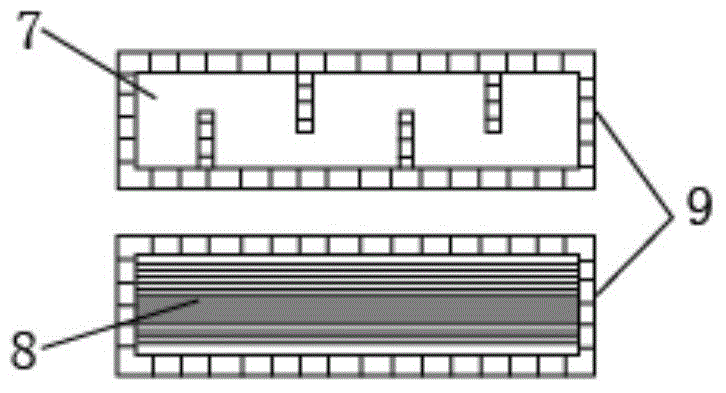

[0019] Such as figure 1 As shown, the present invention provides a CPU integrated heat pipe radiator structure, which is characterized in that it includes a flat plate evaporation heat pipe 1 and a rectangular cross-section condensation heat pipe 2. The bottom of the flat evaporating heat pipe 1 is in direct contact with the heat source, and the flat evaporating heat pipe 1 is provided with a fiber liquid-absorbing core structure 4 arranged in layers, and the inside of the rectangular cross-section heat pipe is provided with a through-hole support frame, which can enhance heat transfer. It can also prevent the heat pipe from being greatly deformed under internal pressure, external pressure or alternating pressure, thereby enhancing the strength of the heat pipe. The outside of the rectangular section heat pipe is equipped with heat dissipation fins 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com