Temperature-controllable heating disc with spider-web-shaped surface structure

A technology of surface structure and heating plate, which is applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve the problem that the wafer temperature cannot be controlled quickly and accurately, and achieve the effect of enhancing heat conduction efficiency and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

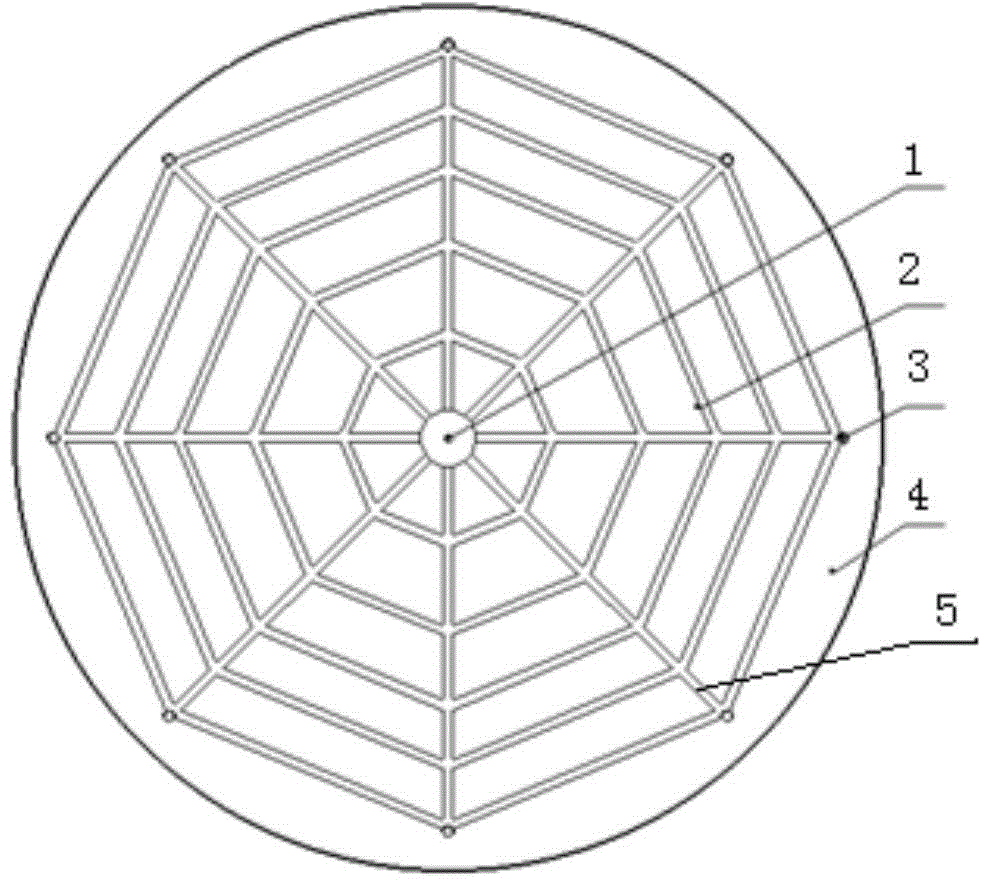

[0013] Such as figure 1 As shown, a temperature-controllable heating plate with a spider web-shaped surface structure includes a heating plate 4 with a central air inlet 1 . The surface of the heating plate 4 is designed with a spider web-shaped groove structure and the edge is formed with gas recovery holes 3 . The spider web-shaped groove structure is composed of N gas flow annular grooves 2 and N gas flow radial grooves 5 arranged along the center of the heating plate 4. The gas flow annular grooves 2 and the gas flow radial grooves The number of grooves depends on actual needs. The above-mentioned annular groove 2 is in contact with and communicates with the gas flow radial groove 5 .

[0014] At least two of the above-mentioned annular grooves 2 and gas flow radial grooves 5 are selected.

[0015] Working principle of the present invention: the heat transfer medium enters the surface of the heating plate 4 from the central air inlet 1 of the heating plate 4, and a circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com