Temperature-controllable heating plate with boss surface structure arranged in polygon shape

A technology of polygonal structure and surface structure, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as the inability to quickly and accurately control the wafer temperature, achieve the effect of enhancing heat conduction efficiency and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

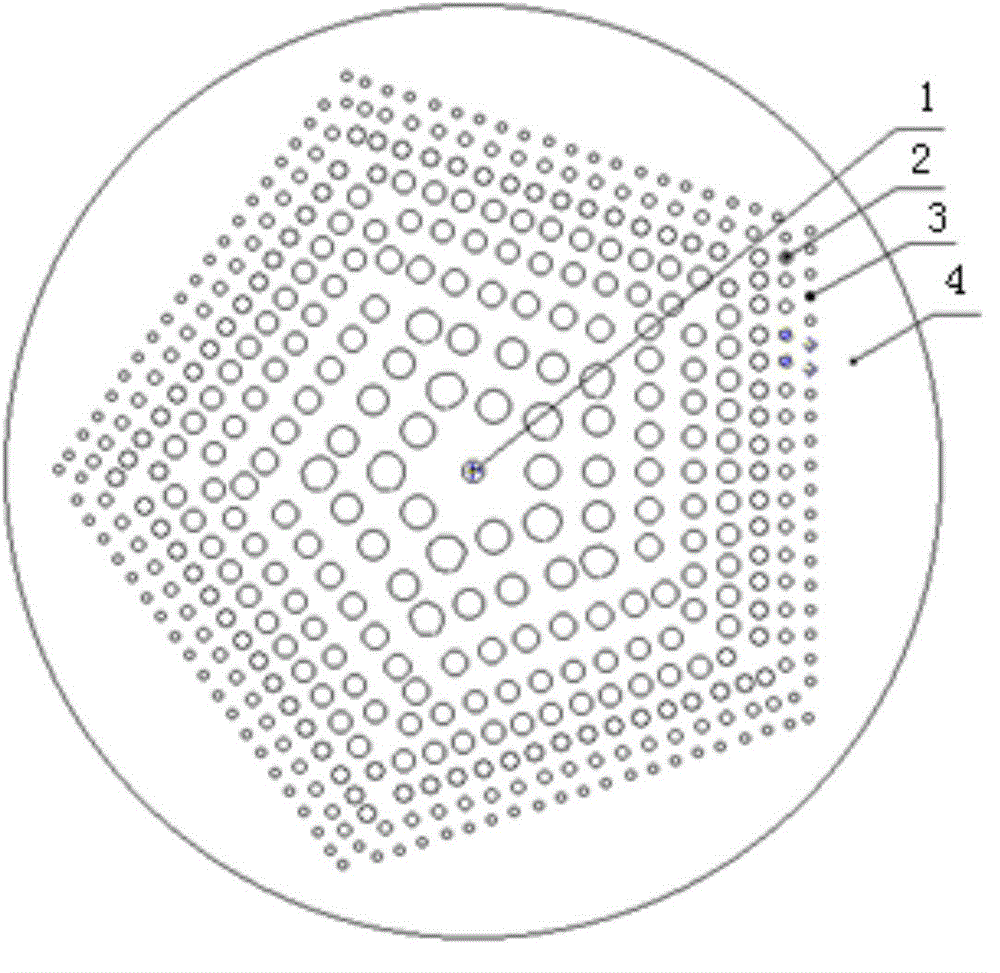

[0013] Such as figure 1 As shown, a temperature-controllable heating plate with polygonal distribution of boss surface structure includes a heating plate 4 with a central air inlet 1 . The outer circumference of the heating plate 4 is provided with a gas recovery hole 3 and N bosses 2 are arranged on the surface, and the N bosses 2 form a polygonal structure.

[0014] The polygonal structure is a regular boss structure such as pentagon, hexagon or octagon;

[0015] There is a gap between the boss 2 and the boss 2;

[0016] The size of the boss 2 on the surface of the heating plate 4 gradually decreases from the middle to the edge.

[0017] Working principle: The heat conduction medium enters the surface of the heating plate from the central air inlet 1 of the heating plate 4, and a certain space in the center is used to release the pressure when the gas enters. The surface of the heating plate 4 has bosses 2 regularly distributed in a polygonal shape. The gap between the bo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap