Knotting mechanism based on bionic principle

A technology of bionic principle and knotting device, which is applied to harvesters, agricultural machinery and implements, applications, etc., can solve problems such as high labor intensity, low knotting efficiency, and difficulty in pushing, so as to reduce agricultural labor costs and improve knotting. Knot efficiency, the effect of improving the success rate of knotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

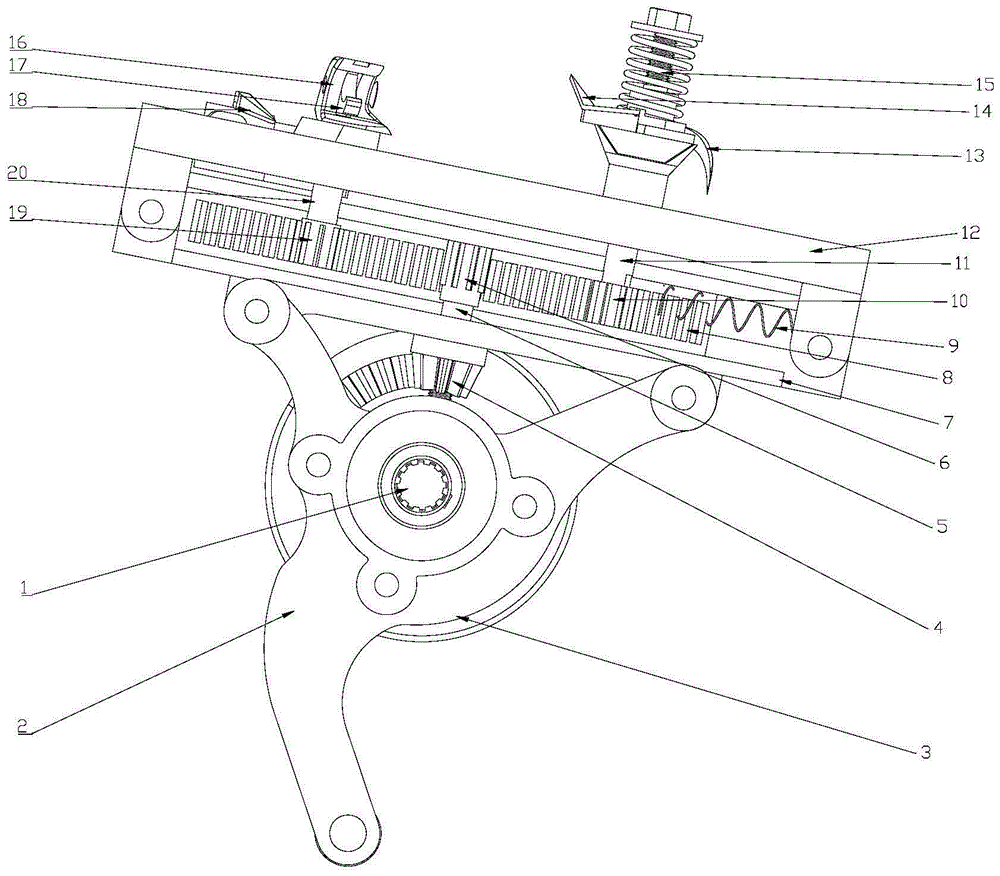

[0018] see figure 1 , The knotting mechanism based on the bionic principle is mainly composed of a fixed frame 2, a knotted fixed frame 12, a winding device, a knotting device, a knotting driving device, a winding driving device and a power transmission device. The power transmission device is arranged on the fixed frame 2 and is connected with the knotting driving device and the winding driving device, and the knotting driving device is connected with the knotting device for driving the knotting device to carry out the knotting operation; the winding driving device and the winding device Connection, used to drive the winding device to carry out the rope winding operation.

[0019] The power transmission device includes a power transmission shaft 1, a bevel gear disc 3, a bevel gear 4, a bevel spur gear shaft 5, a spur gear 6, a rack 8, a rack fixing plate 7 and a rack compression spring 9. The power transmission shaft 1 and the bevel gear disc 3 are fixedly connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com