Dust removing device for plate glass production line and plate glass production line

A technology of flat glass and dust removal equipment, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. The effect of avoiding waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

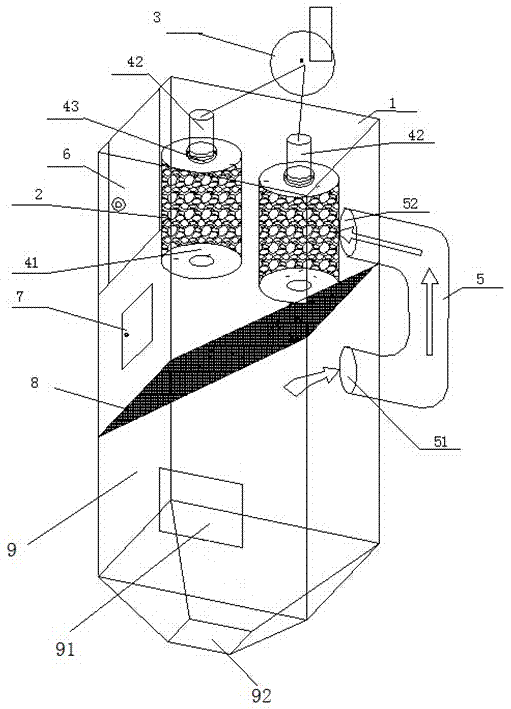

[0034] The present embodiment provides a kind of dust removal equipment for flat glass production line, such as figure 1 As shown, it includes a box body 1 with an accommodation space, the box body 1 is located at the top of the silo 9, and a hollow cylindrical filter element 2 is installed in the interior of the accommodation space through the installation structure. There are two filter elements 2, which are juxtaposed in the horizontal direction and They are arranged at a certain distance inside the accommodation space, and the side wall of one of the filter elements 2 is set at a certain distance from the communication port 52 provided on the box body 1. hole, the aperture of the filter through hole is 0.074mm, and the inner cavity outlet of the filter element 2 is sealed and communicated with the air inlet of the induced draft fan 3; it also includes a connecting pipe 5, and the above connecting pipe 5 is a U-shaped connecting pipe, and the U-shaped connecting pipe has A ...

Embodiment 2

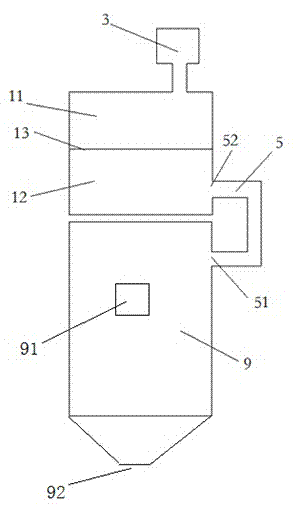

[0069] The present embodiment provides a kind of dust removal equipment for flat glass production line, such as image 3 As shown, it includes a box body with an accommodation space, which is horizontally arranged inside the accommodation space and divides the accommodation space into a first inner chamber 11 (ie, upper chamber) communicated with the induced draft fan 3 and a second inner chamber communicated with the silo 9 12 (i.e. the lower chamber) filter screen 13, the filter screen 13 is provided with several filter through-holes, the aperture size of the filter through-holes is the same as that of embodiment 1, and can also be deformed accordingly according to the description of embodiment 1.

[0070] After the induced draft fan 3 is started, the dust-laden airflow from the hopper 9 enters the second inner chamber through the connecting pipe 5, and due to the filtering effect of the filter screen 13, the dust will be left in the second inner chamber, and the clean air fl...

Embodiment 3

[0072] This embodiment provides a dust removal device for a flat glass production line, which includes a box body 1 with an accommodation space, which is vertically arranged inside the accommodation space and divides the accommodation space into a first inner chamber (ie, the left chamber) that communicates with the induced draft fan 3 . Cavity) and the filter screen of the second inner cavity (i.e. the right cavity) communicated with the silo 9, several filter through holes are arranged on the filter screen, the aperture size of the filter through holes is the same as that of Example 1, and can also be implemented according to the The description of Example 1 is modified accordingly.

[0073] After the induced draft fan 3 is started, the dust-laden air from the silo 9 enters the second inner cavity through the connecting pipe 5. Due to the filtering effect of the filter, the dust will be left in the second inner cavity, and the clean air passes through the filter and enters th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com