Method for improving liquidity of viscoelastic fluid via high frequency ultrasounds

A high-frequency ultrasonic and viscoelastic technology, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, shaking/oscillating/vibrating mixers, etc., can solve the problem of reducing fluid viscoelasticity and irreversible changes in the chemical properties of viscoelastic fluids , high cost and other issues, to achieve the effect of maintaining fluid stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

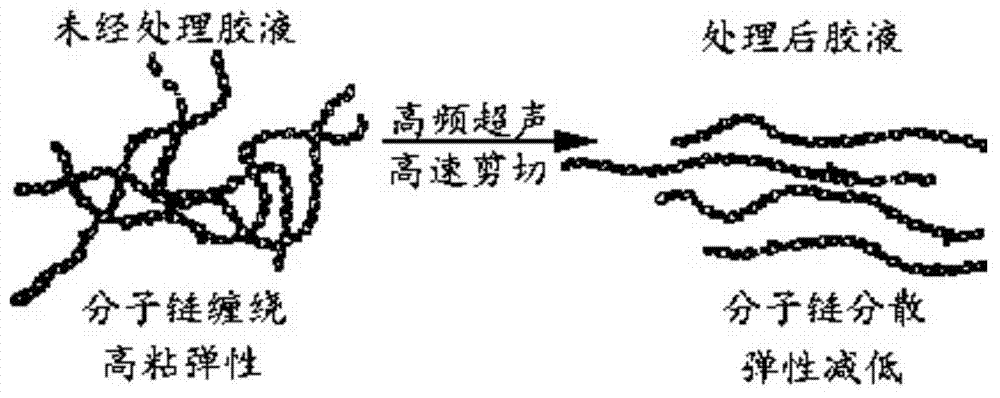

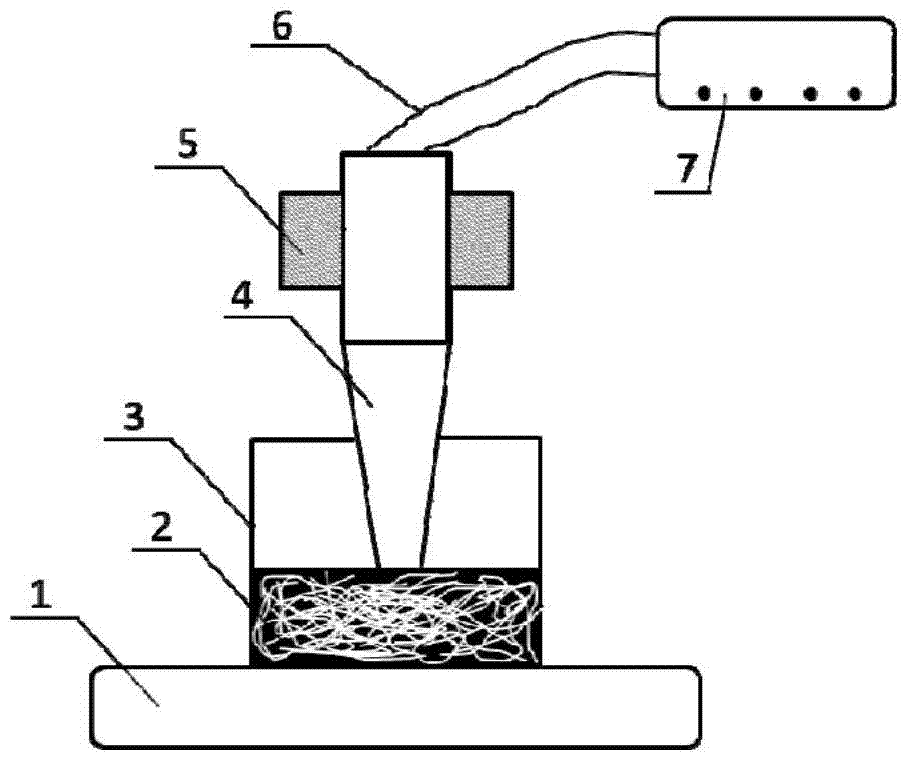

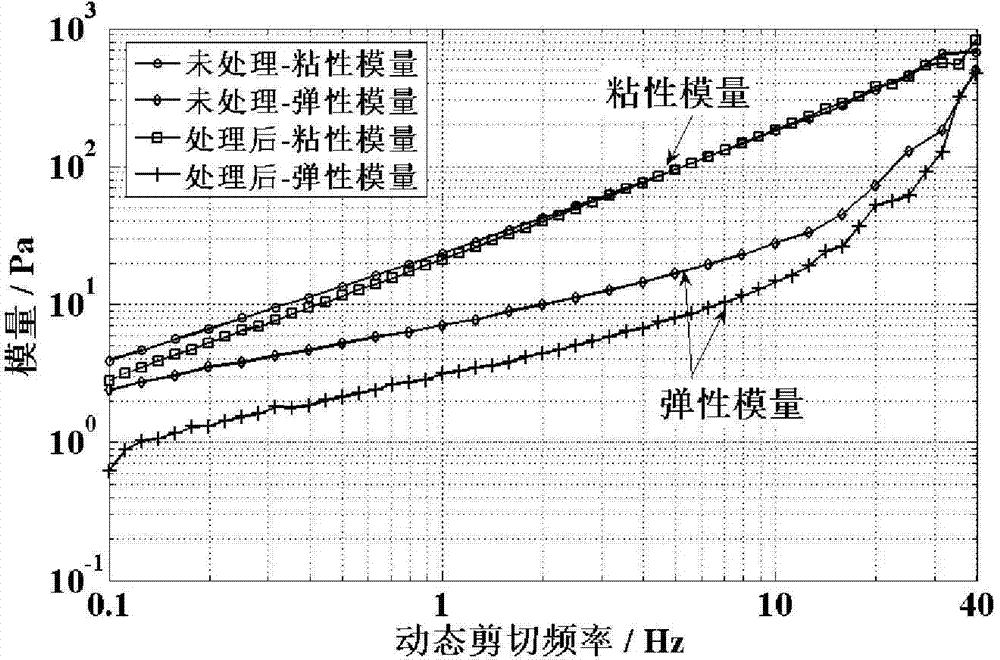

[0023] A method for improving the fluidity of viscoelastic fluid through high-frequency ultrasound, using an ultrasonic horn powered by an ultrasonic power supply, introducing high-frequency ultrasonic waves into the viscoelastic fluid to generate a large number of bubbles, and the shear motion generated by the ultrasonic horn Detonate the bubbles to break up the entangled molecular chains, reduce the viscoelasticity of the viscoelastic fluid, and improve the fluidity of the viscoelastic fluid.

[0024] The working frequency of the ultrasonic horn is 3000-200000Hz, and the power is 1-100W.

[0025] The vibration time of the ultrasonic horn in the viscoelastic fluid is 1-60 minutes.

[0026] The vibration time of the ultrasonic horn in the viscoelastic fluid is 5-8 minutes.

[0027] The viscoelasticity in viscoelastic fluids is mainly determined by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com