A microporous plate for encapsulating a small amount of liquid

A technology of micro-liquid and micro-orifice plate, which is applied in the direction of laboratory containers, laboratory utensils, chemical instruments and methods, etc., can solve the problems of inappropriateness, cumbersome operation, cross-contamination of hole exposure, etc., and prevent warping or scratches, to ensure sealing, to avoid the effect of misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

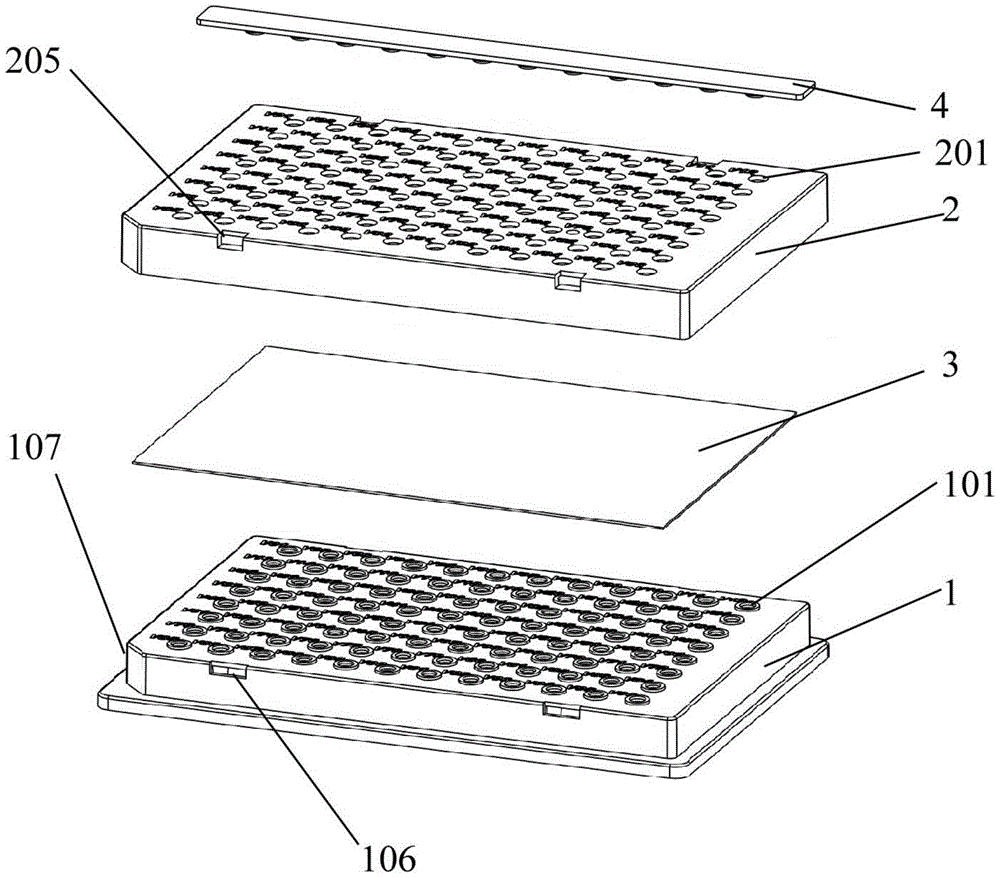

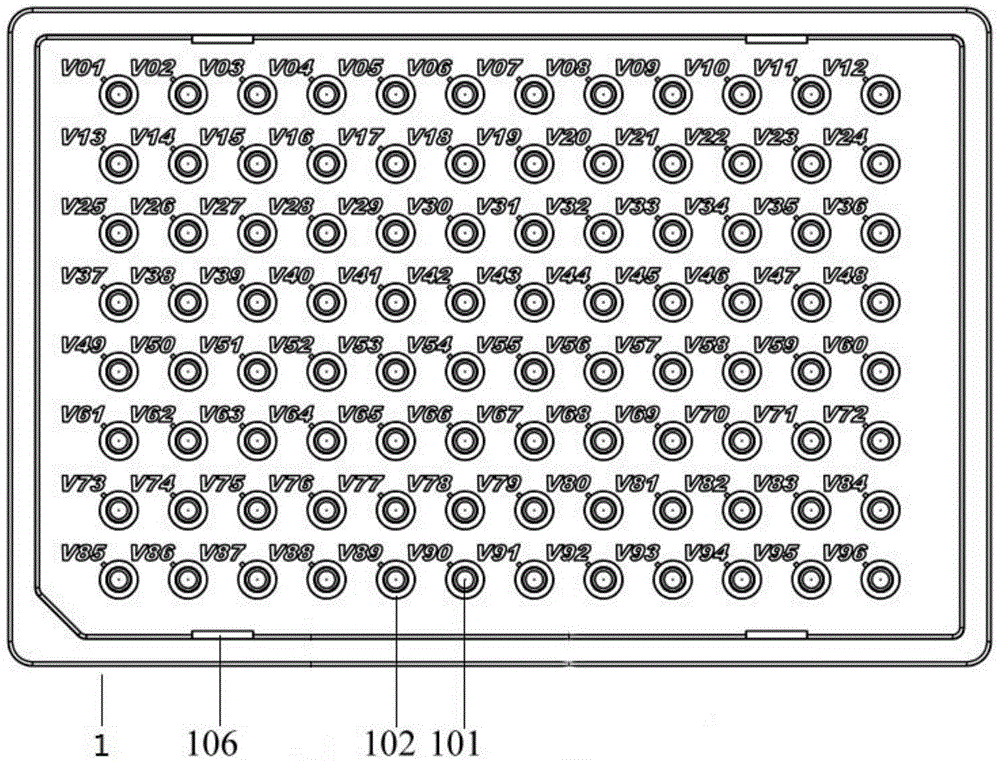

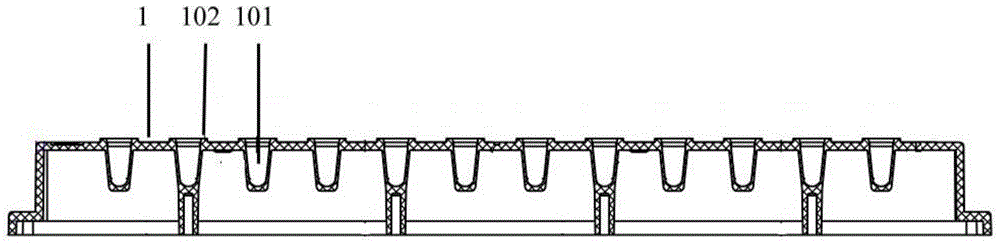

[0060] A microplate that encapsulates tiny amounts of liquid, such as figure 1 , figure 2 and image 3 As shown in the figure, it includes a microwell plate body 1 and a microwell plate cover 2 matched with it. The microwell plate body 1 is provided with a number of microwell cavities 101, and the microwell plate cover 2 is provided with a plate corresponding to the microwell cavity 101. Hole 201, a sealing film 3 is provided between the microwell plate body 1 and the microwell plate cover 2, and the microwell plate cover 2 is provided with a matching sealing plate 4. A sealing stage 102 is provided around the upper opening of the micro-hole cavity 101 . The sealing film 3 is sealed with the microwell plate body 1 by a heat sealing process.

[0061] like Figure 7 As shown, the bottom of the sealing plate 4 is provided with a plastic head cover 401 matching with the plate hole 201 .

[0062] The microwell plate cover 2 is provided with a plurality of snap protrusions 205...

Embodiment 2

[0064] A microplate that encapsulates tiny amounts of liquid, such as figure 1 , figure 2 and image 3 As shown in the figure, it includes a microwell plate body 1 and a microwell plate cover 2 matched with it. The microwell plate body 1 is provided with a number of microwell cavities 101, and the microwell plate cover 2 is provided with a plate corresponding to the microwell cavity 101. Hole 201, a sealing film 3 is provided between the microwell plate body 1 and the microwell plate cover 2, and the microwell plate cover 2 is provided with a matching sealing plate 4. A sealing stage 102 is provided around the upper opening of the micro-hole cavity 101 .

[0065] A press-sealing table 202 matched with the sealing table 102 is arranged around the lower opening of the plate hole 201 . The inner diameter of the opening of the sealing table 202 is smaller than the inner diameter of the opening of the sealing table 102 .

[0066] like Figure 5 As shown, the sealing table 102...

Embodiment 3

[0070] A microplate that encapsulates tiny amounts of liquid, such as figure 1 , figure 2 and image 3 As shown in the figure, it includes a microwell plate body 1 and a microwell plate cover 2 matched with it. The microwell plate body 1 is provided with a number of microwell cavities 101, and the microwell plate cover 2 is provided with a plate corresponding to the microwell cavity 101. Hole 201, a sealing film 3 is provided between the microwell plate body 1 and the microwell plate cover 2, and the microwell plate cover 2 is provided with a matching sealing plate 4. A sealing stage 102 is provided around the upper opening of the micro-hole cavity 101 .

[0071] A press-sealing table 202 matched with the sealing table 102 is arranged around the lower opening of the plate hole 201 . The inner diameter of the opening of the sealing table 202 is smaller than the inner diameter of the opening of the sealing table 102 .

[0072] like Image 6 As shown, the top of the sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com