Trolley for casting sand cores

A cart and sand core technology, which is applied in the field of smelting alloy casting, can solve the problems of increased workload and high working intensity requirements, and achieve the effects of reducing workload, simple structure, and reducing impact or collision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

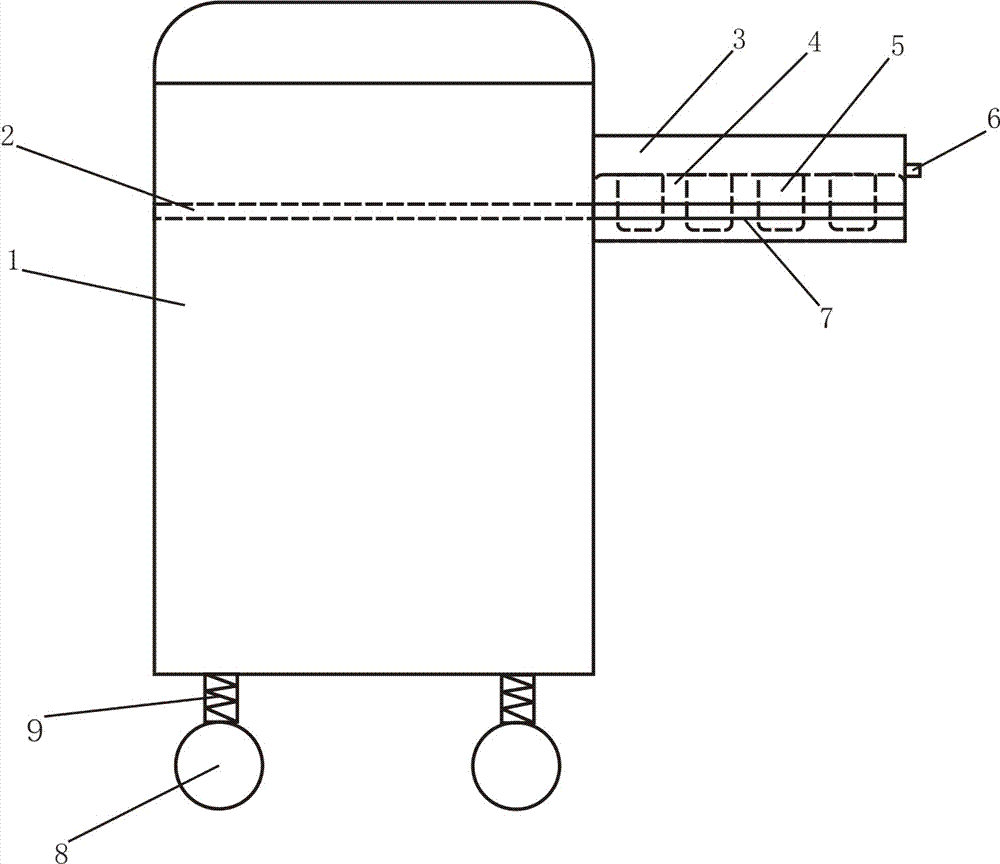

[0009] Now refer to the attached figure 1 , in combination with the embodiment, the specific description is as follows: a trolley for casting sand cores, including a car body 1, a drawer tray 3 is arranged on the car body 1, a slide rail 2 is arranged on the car body 1, and the drawer The pull tray 3 is provided with a chute 6 matching the slide rail, the draw tray 3 is connected with the slideway of the vehicle body 1, and the vehicle body 1 is provided with at least two layers of pull trays 3, so The drawing tray 3 is provided with a bubble box 4, and the bubble box 4 is provided with a groove 5 consistent with the shape of the sand mold. The sand core is placed in the groove of the bubble box, which is safe and reliable, and prevents the sand core from being damaged due to collision. The lower end of the car body 1 is provided with a universal wheel 8, and a buffer spring 9 is arranged between the car body 1 and the universal wheel 8 to absorb the shock of the car body and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com