A method for lapping and polishing flexible joints with thin neck abrasive flow

A technology of flexible joints and abrasive flow, applied in the direction of grinding/polishing equipment, grinding machines, surface polishing machine tools, etc., can solve the problems of bell mouth and processing effect relying on workers, etc., to reduce the difficulty of equipment design, improve quality, and improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

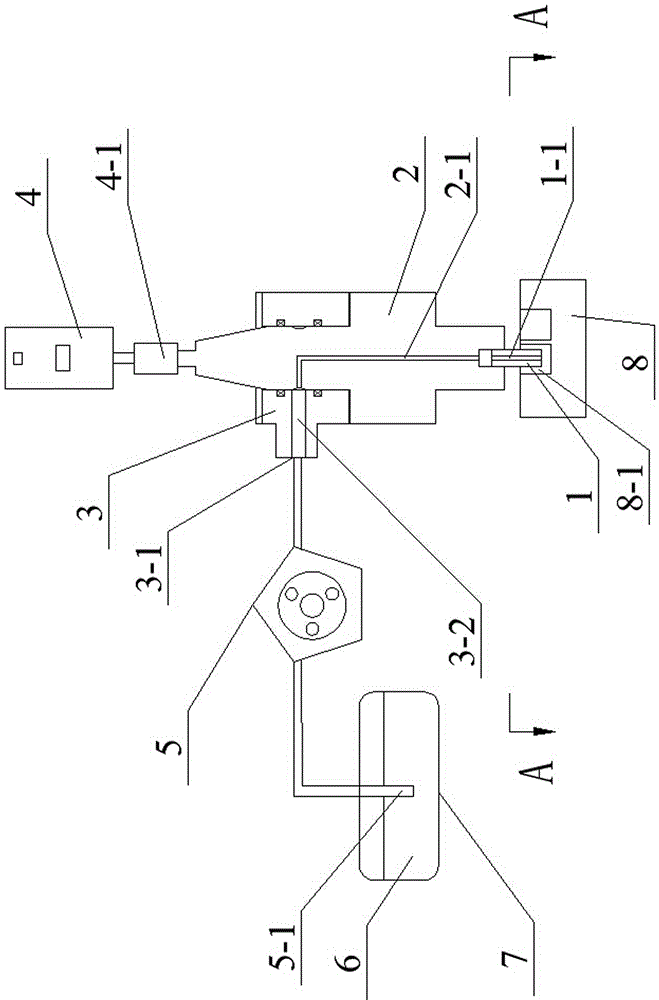

[0018] Specific implementation mode one: combine figure 1 and figure 2 As shown, its method steps are:

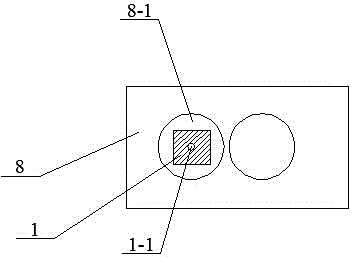

[0019] Step 1: Place the fluid abrasive processing fluid 6 in the container groove 7, then place the workpiece 8 under the polishing head 1, and insert the polishing head 1 into the deep hole of the workpiece 8, so that the polishing head There is a gap 8-1 between the outer surface of 1 and the inner circular surface of the deep hole of the workpiece 8, so that the lower end of the polishing head 1 is close to the bottom of the deep hole, but the two do not touch each other;

[0020] Step 2: Turn on the peristaltic pump 5, the inlet of the peristaltic pump 5 sucks the fluid abrasive processing fluid 6 in the container tank 7 through the tail port of the pipeline 5-1, and then the peristaltic pump 5 passes through its outlet, the pipeline, and the fixed adapter 3 The liquid inlet port 3-1 of the fixed adapter 3 and the internal channel 2-1 of the rotating chuck 2 transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com