Silica oxygen-free chlorination and acid extraction treatment method and device

A silicon dioxide and acid extraction technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of complex chlorination acid extraction treatment methods, low work efficiency, high production cost, etc., achieve good effect, improve effect, and chlorinate high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

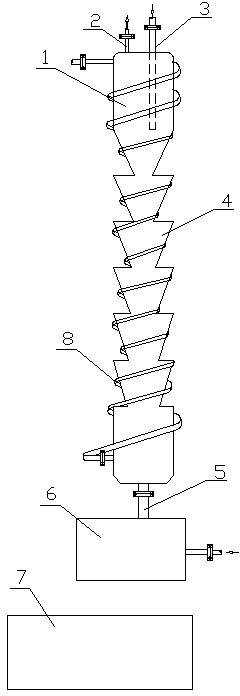

[0016] Embodiment 1, with reference to accompanying drawing, a kind of silicon dioxide anaerobic chlorination acid extraction device comprises vertical chlorination reaction furnace, acid extraction tank 6 and specific gravity separation tank 7; The discharge port of the vertical chlorination reaction furnace is connected, and the specific gravity separation tank 7 is arranged below the acid extraction tank 6; the vertical chlorination reaction furnace is provided with a shell, and a corrosion-resistant furnace body 1 full of a magnetic field is provided in the shell. , the magnetic field is formed by a magnet arranged outside the furnace body 1 . An insulating layer is provided between the shell and the furnace body 1, the top of the furnace body 1 is provided with an air outlet and a feed port, and the feed port is provided with a feed pipe inserted into the furnace body 1, and the furnace body 1 The bottom end is connected with a discharge pipe 5, and the lower side of the ...

Embodiment 2

[0018] Embodiment 2, in the silicon dioxide anaerobic chlorination acid extraction device described in embodiment 1, the total height of the truncated cone is 1800mm, and the diameter of the furnace body 1 is 120cm.

Embodiment 3

[0019] Example 3, in the silicon dioxide oxygen-free chlorination acid extraction device described in Example 1, the diameter ratio of the bottom surface of the truncated cone from bottom to top is 3.5:3:2.5:2:1.5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com