Gamma-MnO2 preparation method

A technology of manganese sulfate solution and potassium permanganate, which is applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of high cost, complicated preparation process, and environmental pollution, and achieve good crystallinity, simple operation of the preparation process, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

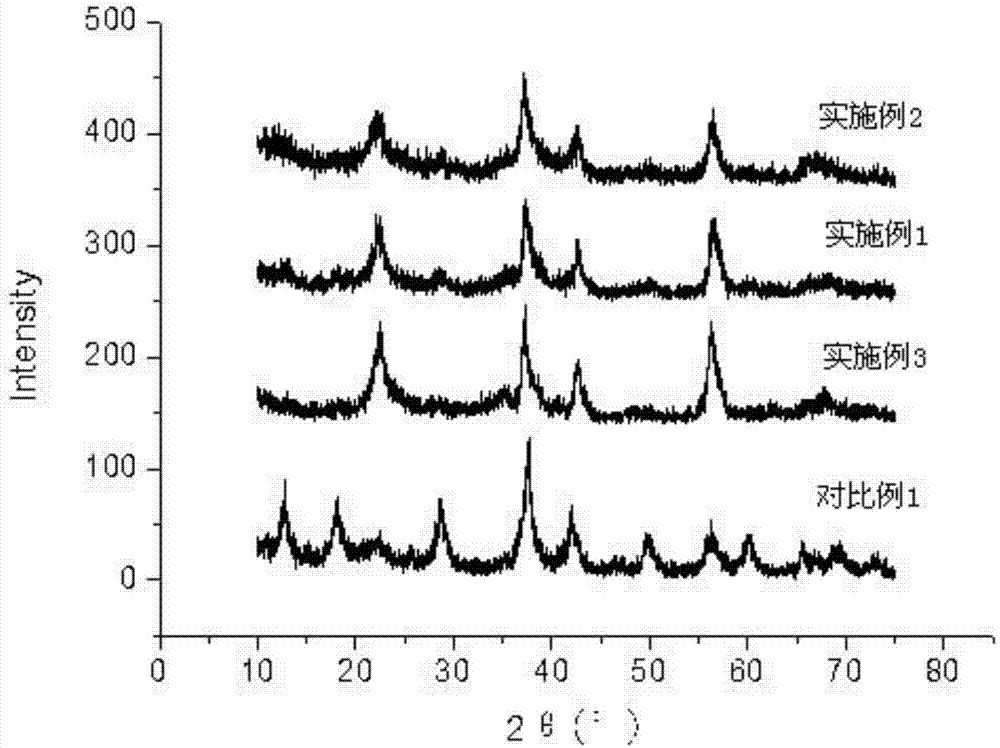

Examples

Embodiment 1

[0026] A, preparing mass fraction respectively is that the potassium permanganate solution of 3.06% and the manganese sulfate solution that mass fraction is 4.33%;

[0027] b. Heat the potassium permanganate solution and the manganese sulfate solution described in step a to 95°C respectively, and keep the temperature for 12min;

[0028] C, the manganese sulfate solution and the potassium permanganate solution after being incubated in the step b are respectively subjected to electric pulse treatment, the frequency is 4HZ, the voltage is 500V, and the treatment time is 90s;

[0029] d. Mix the manganese sulfate solution and potassium permanganate solution after the electric pulse treatment according to the volume ratio of 1:1 to obtain a mixed solution, then put the mixed solution in a G4 funnel, and pump it after standing for 24 hours filter;

[0030] e. Wash the solid obtained by filtering in step d with deionized water for 3 times, then place the cleaned solid in a beaker, p...

Embodiment 2

[0032] A, preparing mass fraction respectively is that the potassium permanganate solution of 3.06% and the manganese sulfate solution that mass fraction is 4.33%;

[0033] b. Heat the potassium permanganate solution and the manganese sulfate solution described in step a to 90°C respectively, and keep the temperature for 15min;

[0034] C, the manganese sulfate solution and the potassium permanganate solution after being incubated in the step b are respectively subjected to electric pulse treatment, the frequency is 3HZ, the voltage is 600V, and the treatment time is 60s;

[0035] d. Mix the manganese sulfate solution and potassium permanganate solution after the electric pulse treatment according to the volume ratio of 1:0.95 to obtain a mixed solution, then put the mixed solution in a G4 funnel, and pump it after standing for 24 hours filter;

[0036] e. Wash the solid obtained by filtering in step d with deionized water for 3 times, then place the cleaned solid in a beaker...

Embodiment 3

[0038] A, preparing mass fraction respectively is that the potassium permanganate solution of 3.06% and the manganese sulfate solution that mass fraction is 4.33%;

[0039] b. Heat the potassium permanganate solution and the manganese sulfate solution described in step a to 100°C respectively, and keep the temperature for 10min;

[0040] C, the manganese sulfate solution and the potassium permanganate solution after being incubated in the step b are respectively subjected to electric pulse treatment, the frequency is 5HZ, the voltage is 400V, and the treatment time is 120s;

[0041] d. Mix the manganese sulfate solution and potassium permanganate solution after the electric pulse treatment according to the volume ratio of 1:1.05 to obtain a mixed solution, then put the mixed solution in a G4 funnel, and pump it after standing for 24 hours filter;

[0042] e. Wash the solid obtained by filtering in step d with deionized water for 3 times, then place the cleaned solid in a beak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com