Spiral guide type submersible jet aerator

A technology of spiral diversion and jet aeration, which is applied in water aeration, water/sludge/sewage treatment, sustainable biological treatment, etc. It can solve the problem of clogging and protecting the aeration head, large eccentric vibration, and affecting the full integration of water and air. To achieve the effect of strengthening the effect of sludge reflux, reducing power costs, and shortening aeration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

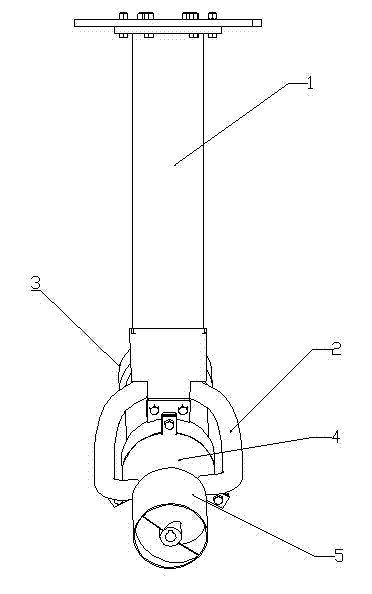

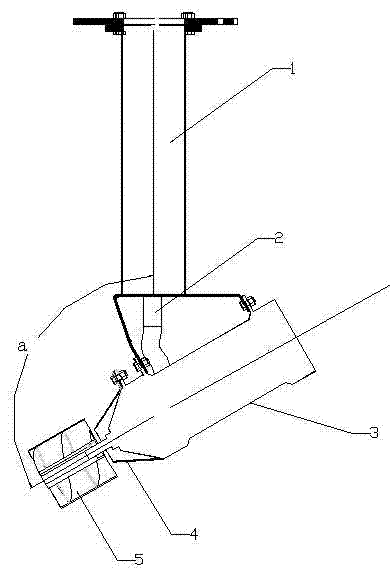

[0018] Specific implementation methods: such as figure 1 As shown, a spiral diversion type submersible jet aerator includes a submersible motor 3 fixed underwater through a support rod 1. The support rod 1 is a hollow pipe, and an air intake pipe 2 is arranged in the pipe. The front end of the submersible motor 3 A flow mixer 4 is provided, and the air inlet pipe 2 is connected to the flow mixer 4. The front end of the flow mixer 4 is provided with a spiral deflector 5; There is a helical blade inside, the central axis of the helical blade runs through the flow mixer and is fixedly connected with the motor shaft; the helical blade is fixedly connected with the guide cylinder. The flow mixer 4 is conical, and the inlet ports of the flow mixer are arranged on the left and right sides of the flow mixer respectively. The water inlet channel is between the spiral deflector 5 and the flow mixer 4, and the inner cavity of the flow mixer 4 is an air intake channel. like figure 2 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap