Novel method for compounding medicament of Enzalutamide for resisting prostate cancer

A technology of enzalutamide and a new method, which is applied in the field of pharmaceutical synthesis technology, can solve the problems that restrict enzalutamide scale-up production, etc., and achieve the effects of good industrial scale-up prospects, mild operating conditions, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

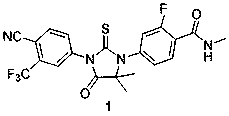

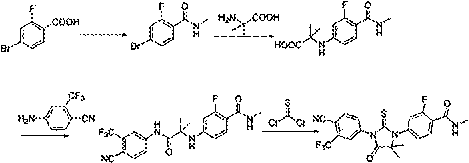

[0038] Preparation of N-(3-trifluoromethyl-4-cyano-phenyl)-N-(3-fluoro-4-carboxamidophenyl)-urea

[0039] 150ml of THF was added to a 250ml three-necked flask, 18.6g of 3-trifluoromethyl-4-cyano-aniline, 16.8g of 2-fluoro-4-amino-benzamide and 16.2g of CDI were sequentially added with stirring. Heat to reflux, react for 8h, TLC monitors the completion of the reaction. The reaction solution was concentrated to dryness under reduced pressure, and the residue was purified by column chromatography to obtain N-(3-trifluoromethyl-4-cyano-phenyl)-N-(3-fluoro-4-carboxamidophenyl) -Urea 33.4g, yield 88.1%.

Embodiment 2

[0041] Preparation of N-(3-trifluoromethyl-4-cyano-phenyl)-N-(3-fluoro-4-carboxamidophenyl)-thiourea

[0042] Add 300ml of toluene into a 500ml three-necked flask, and add 33.4g of N-(3-trifluoromethyl-4-cyano-phenyl)-N-(3-fluoro-4-carboxylphenyl) in sequence while stirring )-Urea and 35.5 g of Lowe's reagent, heated to reflux, stirred for 3 hours, TLC monitored the completion of the reaction. The reaction solution was concentrated to dryness under reduced pressure, and the residue was purified by column chromatography to obtain 25.2 g of N-(3-trifluoromethyl-4-cyano-phenyl)-N-(3-fluoro-4-carboxamide benzene Base)-thiourea, the yield is 72.3%.

Embodiment 3

[0044] Preparation of Enzalutamide

[0045] Add 150ml DMF into a 250ml three-necked flask, and add 25.2g N-(3-trifluoromethyl-4-cyano-phenyl)-N-(3-fluoro-4-carboxamide phenyl) with stirring. )-Thiourea, 8.7g of methyl 2-methyl-2-chloropropionate, and 6.4g of triethylamine, heated to an internal temperature of 80-90°C, reacted for 5h, and TLC monitored the completion of the reaction. Return to room temperature, add the reaction solution to 600 ml of water, and filter to obtain a crude product. After drying, column chromatography purification was performed to obtain 19.6 g of enzalutamide with a yield of 66.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com