Precast integral casting #-shaped floor structure

A well-shaped, prefabricated component technology, applied to floors, building components, building structures, etc., can solve the problems of unfavorable structure anti-seismic, structural self-heavy, complex force of the floor, etc., so as to reduce the workload of steel bar connection and improve the shear resistance The effect of carrying capacity and convenient production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

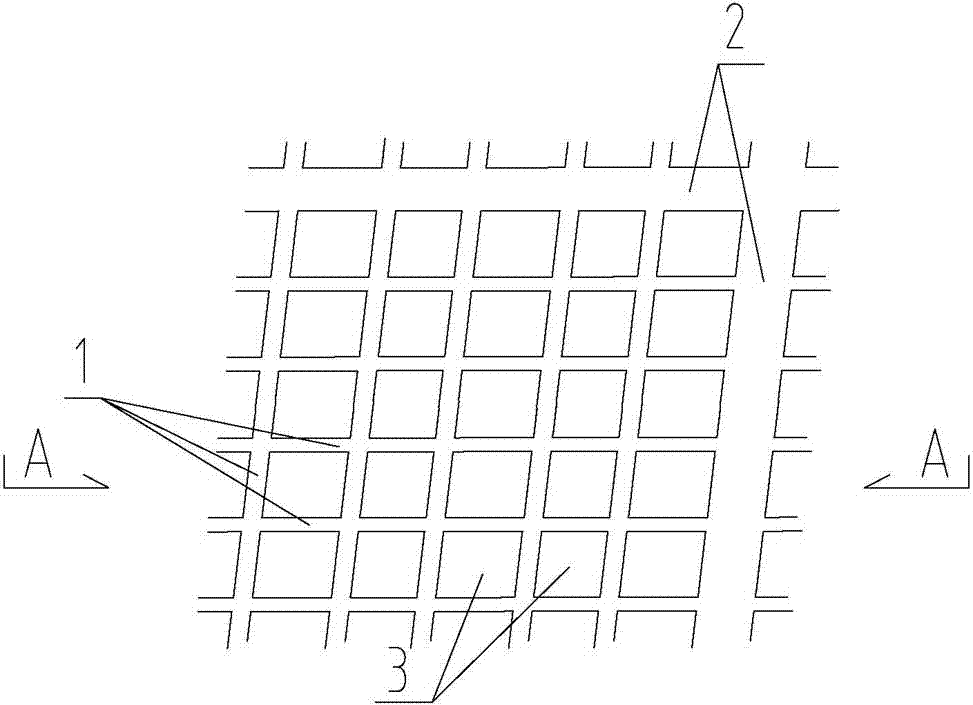

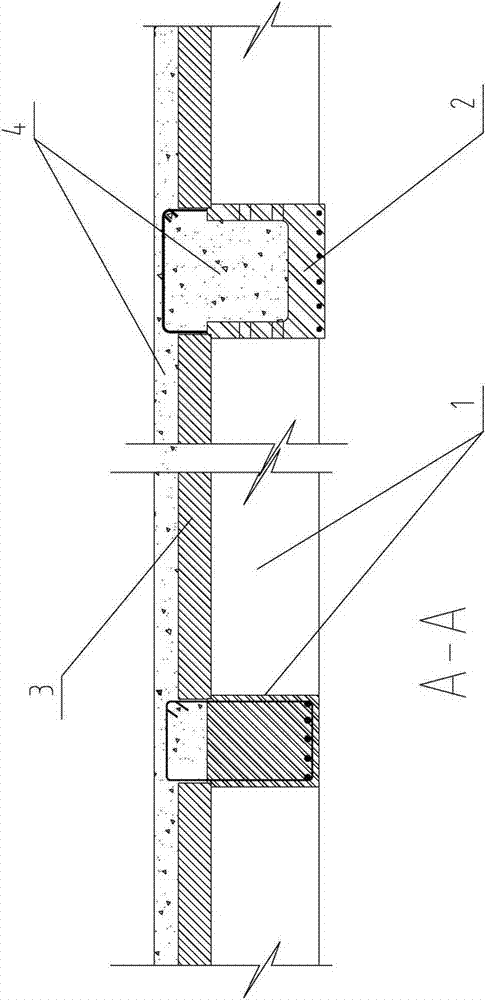

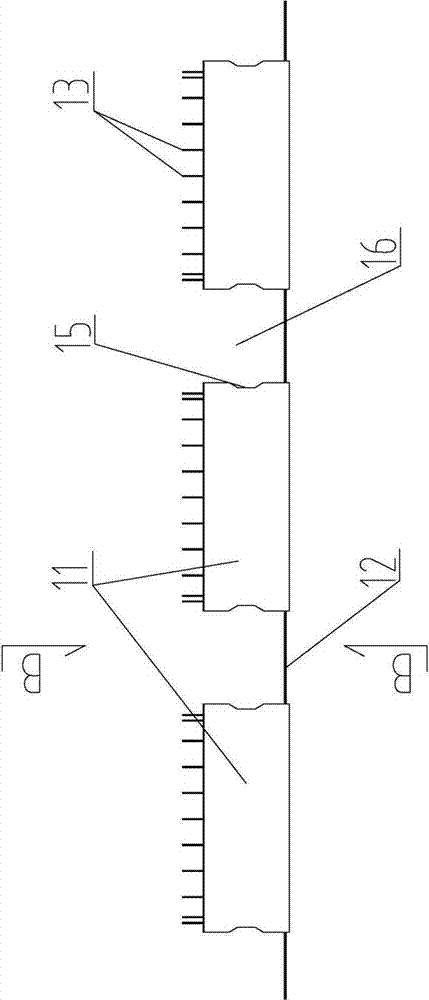

[0033] Please refer to the attached figure 1 To attach Figure 8 As shown, the present invention is a prefabricated integral pouring well-shaped floor structure, which is composed of prefabricated laminated secondary beam prefabricated component 1, prefabricated laminated frame beam prefabricated component 2, prefabricated laminated slab prefabricated component 3 and laminated cast-in-place structure 4 And so on several parts.

[0034] Wherein, the prefabricated composite secondary beam prefabricated components 1 and the prefabricated composite frame beam prefabricated components 2 are arranged in a square shape and vertically intersect each other. The prefabricated composite slab prefabricated component 3 is placed on the prefabricated composite secondary beam prefabricated component 1 and the prefabricated composite frame beam prefabricated component 2 . The composite cast-in-place structure 4 is poured on the prefabricated composite secondary beam prefabricated component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com