Drilling module drill pipe ramp for offshore cluster wells

A technology for marine cluster wells and drill pipe ramps, which is applied in the direction of drill pipes, drilling equipment, and drill pipes, and can solve the problems of difficulty in meeting the requirements of drilling operations, the increase in the total weight of equipment and the direct cost of equipment manufacturing, and the time spent on drill pipe ramps. Indirect cost increase and other issues can be avoided to avoid the increase of equipment procurement and operation costs, reduce equipment procurement costs and drilling operation costs, and improve integration and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

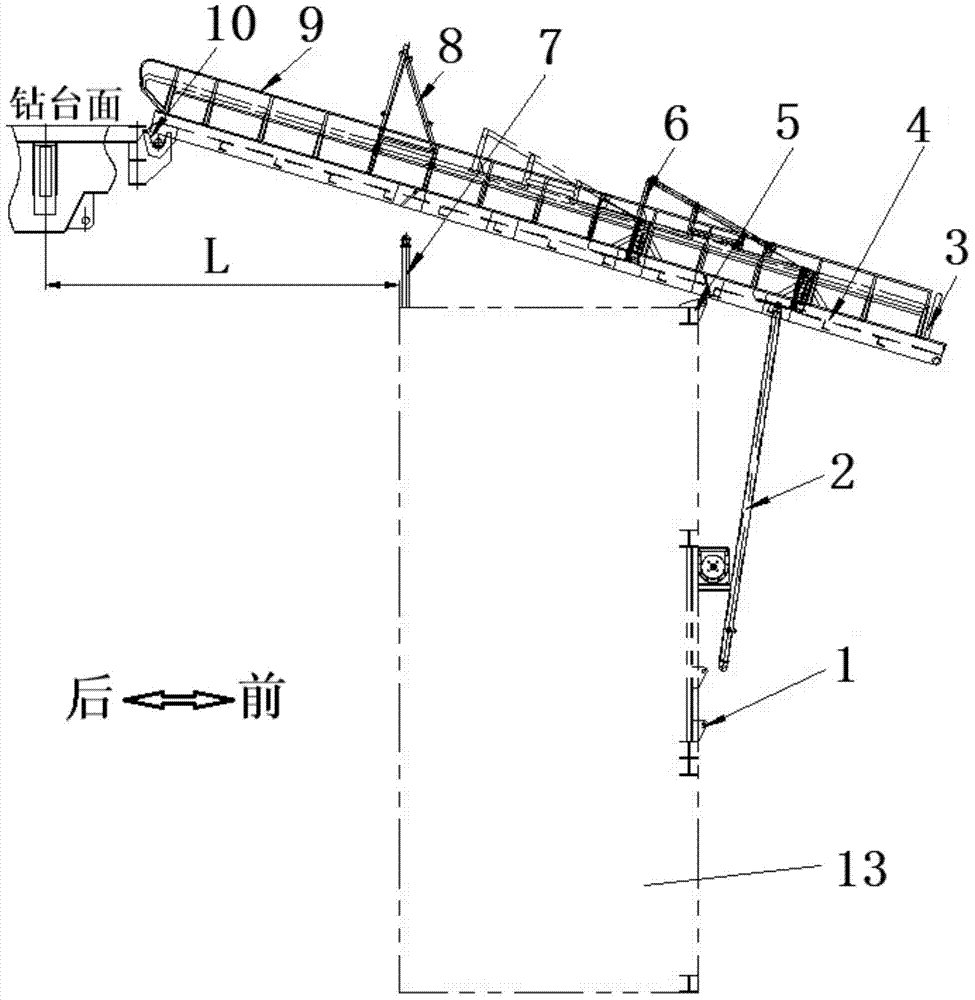

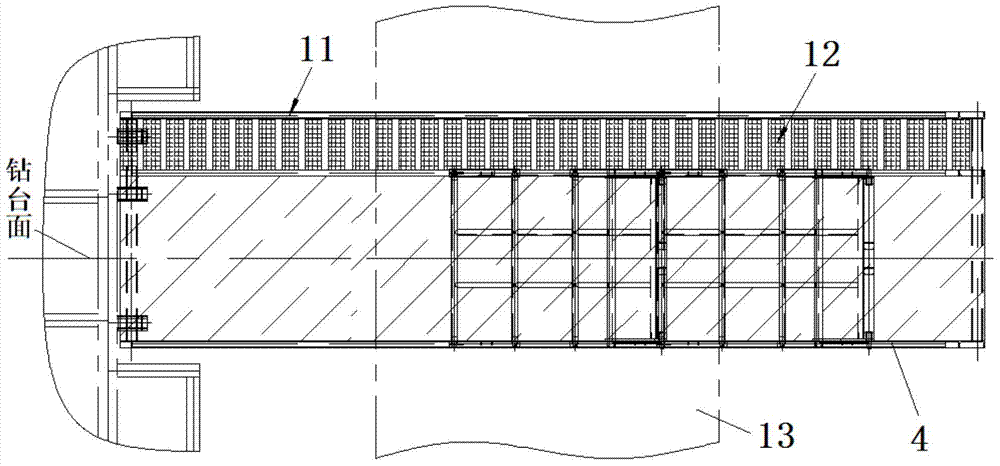

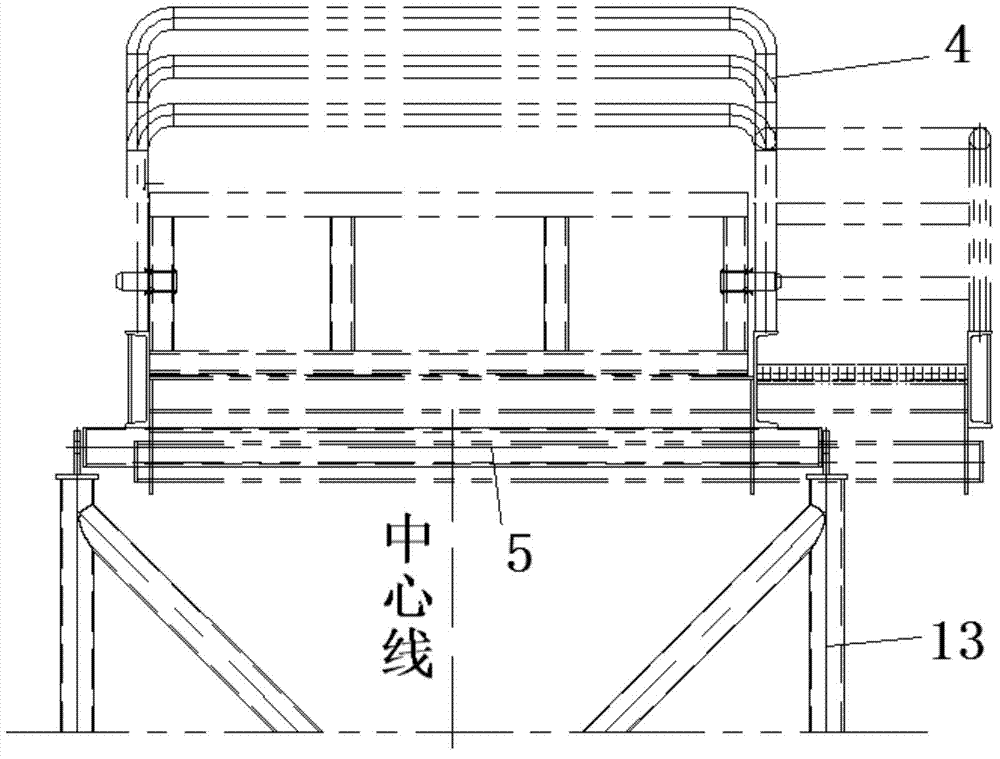

[0025] refer to figure 1 , figure 2 , image 3 , Figure 4 , the structure of the present invention is to include a steel structure frame 13, the steel structure frame 13 and the solid control system are called the solid control system module together, the support ear plate 1 is fixedly connected to the front side of the steel structure frame 13, and the top of the steel structure frame 13 A front roll bar 5 and a rear roll bar 7 are respectively provided;

[0026] The supporting lug 1 is hinged to the front of the ramp main body 4 through the strut 2, and the rear end of the ramp main body 4 is hinged to the drill floor surface through the connecting ear plate 10; the front roll bar 5 and the rear roll bar 7 are located under the ramp main body 4, The lifting position of the ramp main body 4 is supported;

[0027] A guardrail 9, an esc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com