Driving system of shield tunneling machine and shield tunneling machine comprising driving system

A drive system and shield machine technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of high drive power of the cutter head, limited escape torque, and small escape torque, so as to improve drive efficiency and enhance drive efficiency , The effect of enhancing the ability to escape from difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

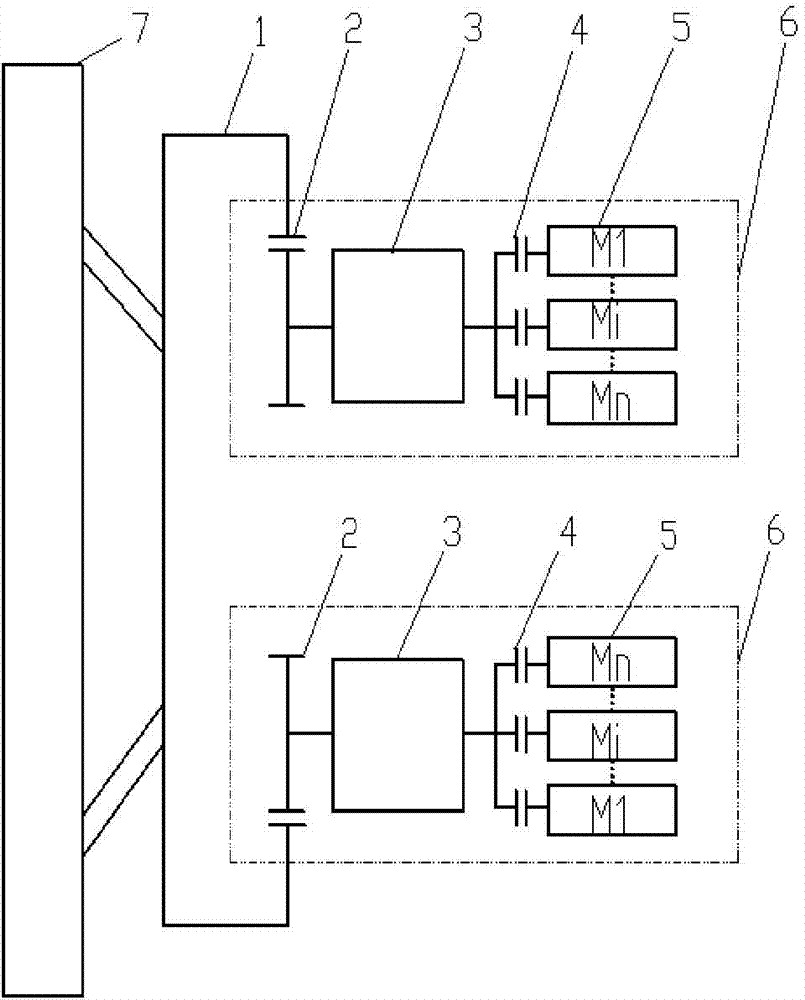

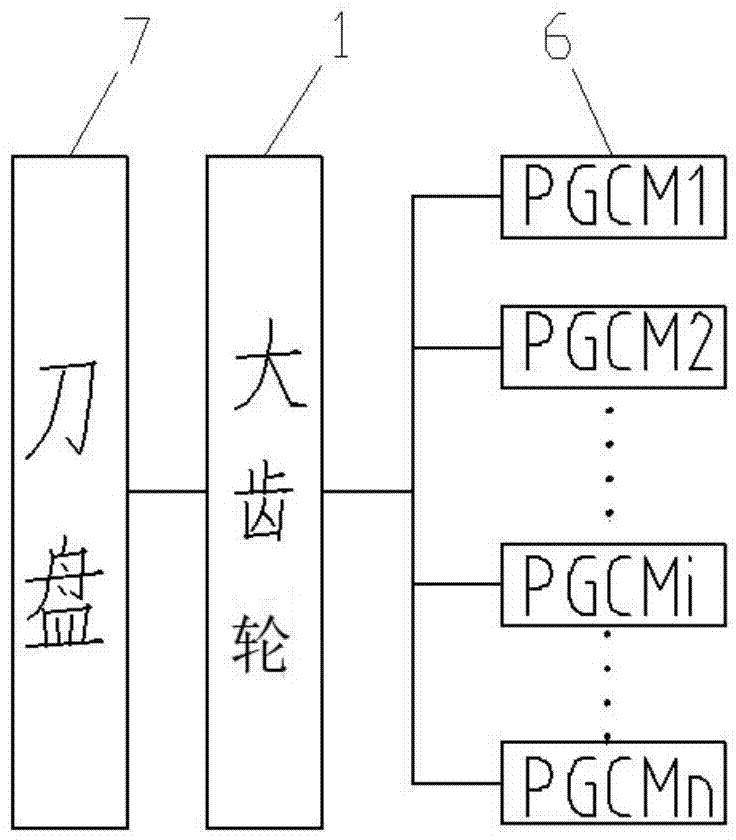

[0032] A drive system for a shield machine cutter head, see figure 1 , specifically including a large gear 1 arranged on the cutter head 7 and a drive unit 6 connected with the large gear 1 .

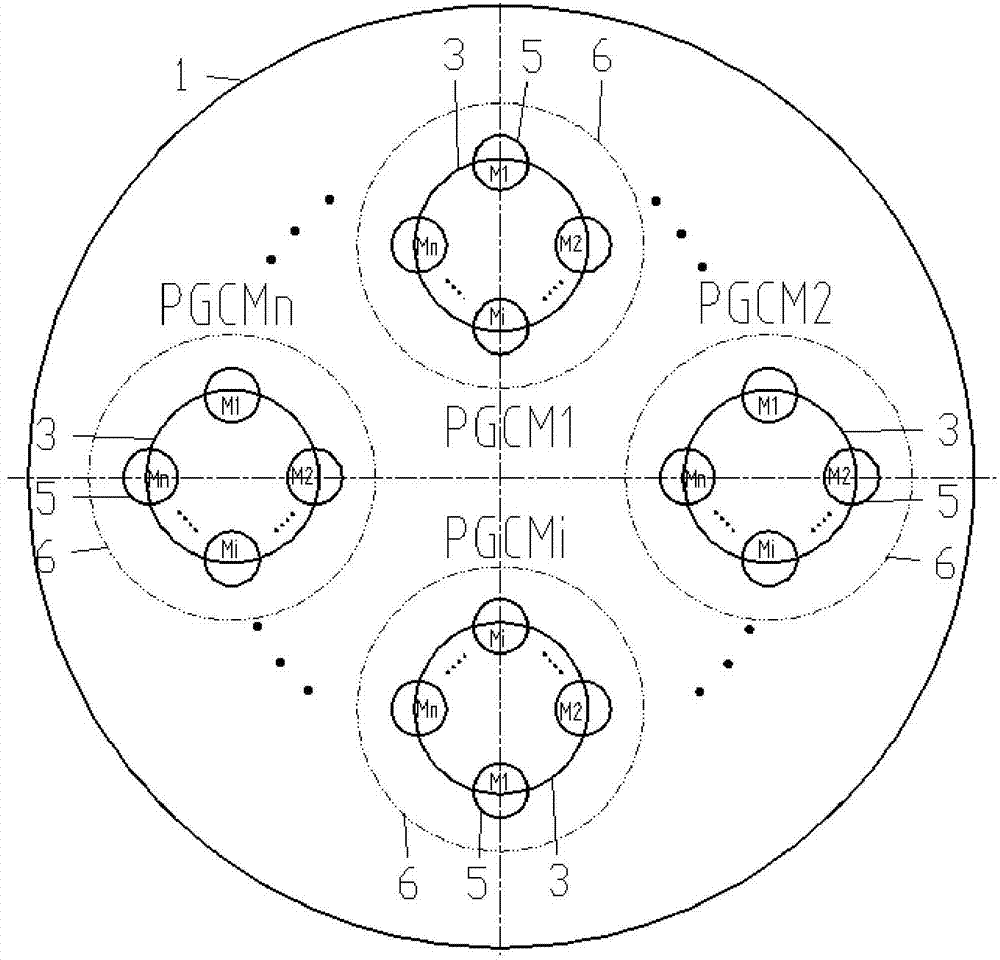

[0033] The number of the drive units 6 is n, and the value of n can be 1, or 2, or other numbers of more than 2, and the specific number can be selected according to actual needs. When the value of n is greater than or equal to 2, the drive units 6 are connected in parallel (connected in parallel with each other) and are uniformly arranged in a ring with the center of the cutterhead as the center (see image 3 ), which is conducive to the symmetrical distribution of the power output by the driving source on the large gear, which is beneficial to the force balance of the large gear, and improves the driving characteristics and service life of the ring gear; the combination of multiple drive units can be used simultaneously or partially. The advantages of easy installation, improved driv...

Embodiment 2

[0043] A shield machine, comprising a cutter head and the drive system of the shield machine cutter head as described in Embodiment 1 connected to the cutter head, the shield machine adopts such a drive system, so that the shield machine has geological adaptability Strong, high utilization rate of installed power, large torque, easy installation, and strong practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com