Low-compression-ratio and fully-oilless scroll air compressor assembly

An air compressor, low compression ratio technology, applied in the field of compressors, can solve the problems of increasing the difficulty of product marketization, low work efficiency, large leakage ratio and friction heat, etc., to achieve low manufacturing cost, high work efficiency, product Effectiveness of tightness and stability assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

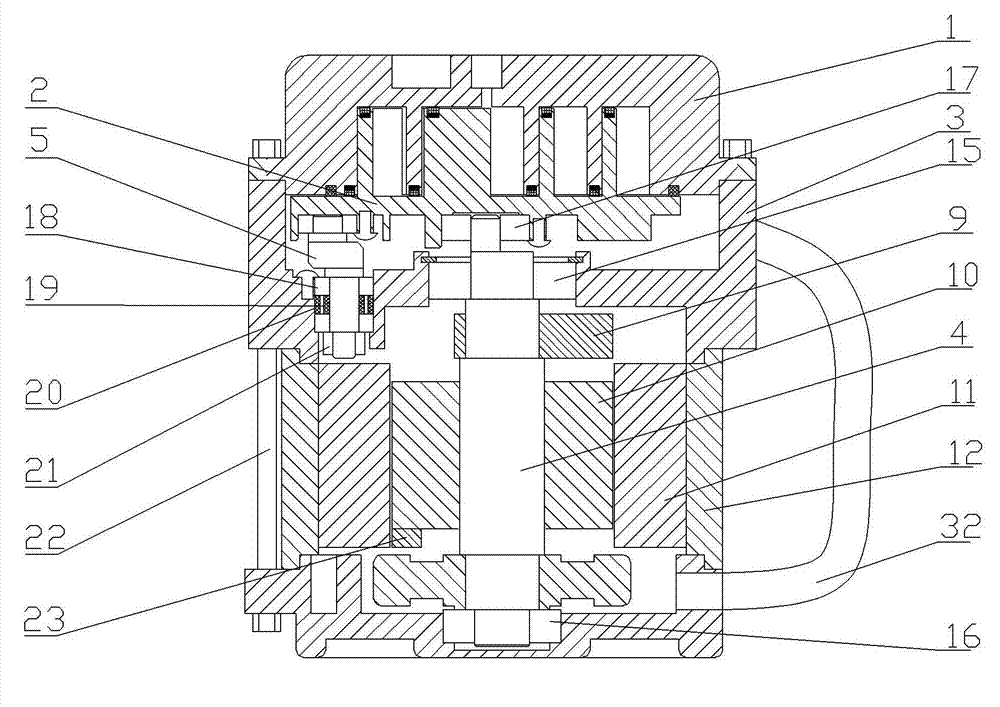

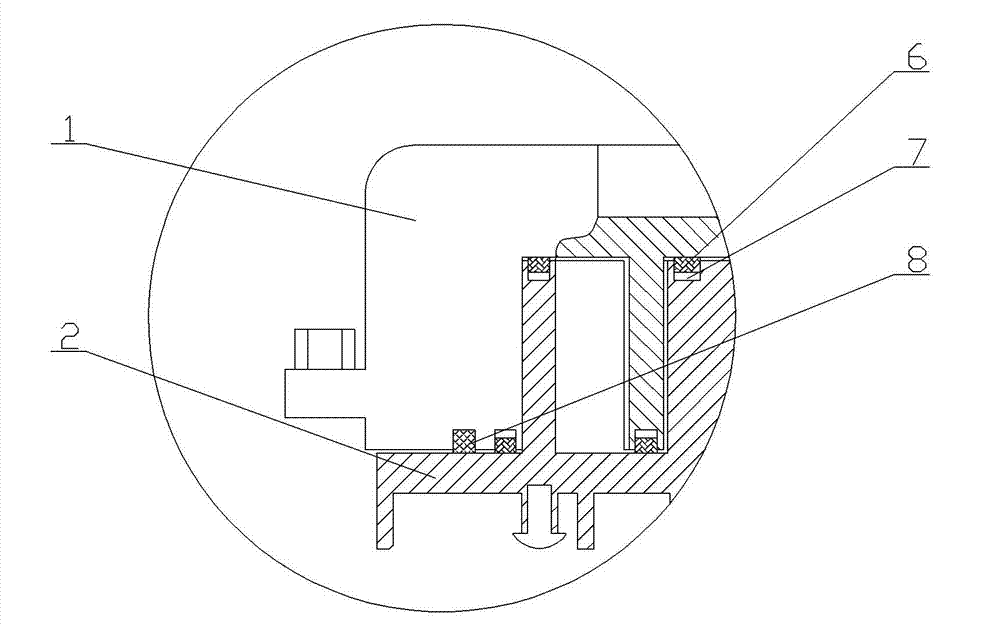

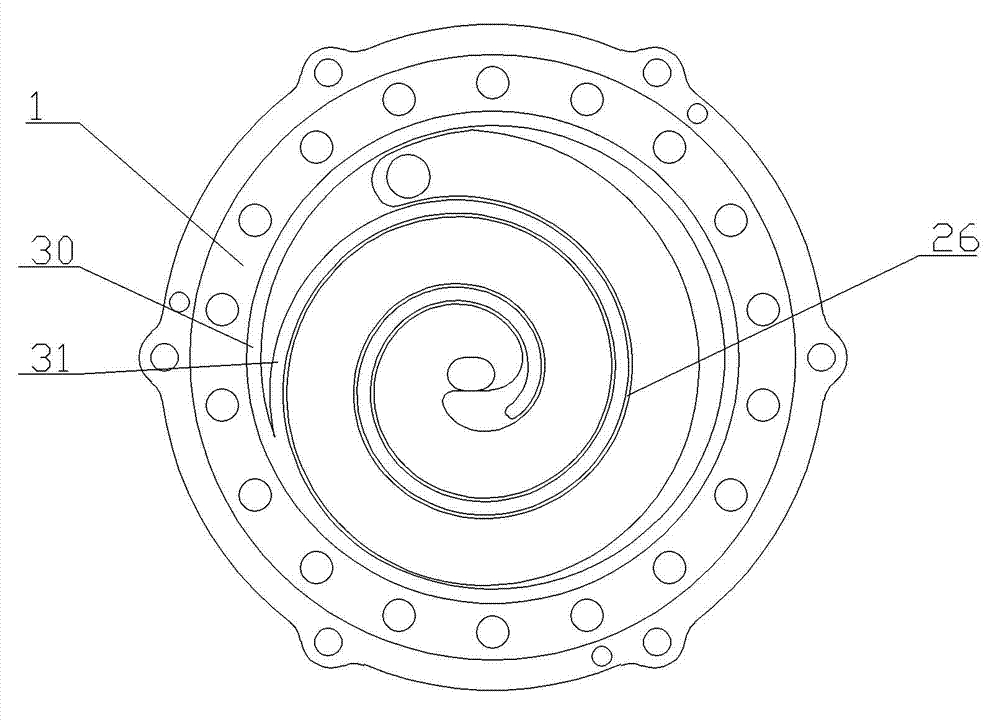

[0025] As shown in the figure, the present invention includes a main engine casing and an orbiting scroll. The main points of the structure are that the main engine casing is connected with the movable scroll above the middle part of the main engine casing through a three-axis anti-rotation assembly, and the upper end of the orbiting scroll is set There is a fixed scroll, and the edge of the fixed scroll is connected to the upper end of the edge of the main engine casing; the middle part of the lower end surface of the movable scroll is provided with a main drive bearing installation groove, and the middle part of the main engine casing is provided with a motor front bearing corresponding to the main drive bearing installation groove. Mounting hole, the lower end of the main engine casing is connected to the upper end of the stator casing, the lower end of the stator casing is connected to the rear frame of the motor, the periphery of the motor rear frame, the periphery of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com