Integrated crossed roller bearing for harmonic speed reducer

A technology of cross roller bearings and harmonic reducers, which is applied in the direction of rolling contact bearings, bearings, flexible bearings, etc., can solve the problems of the overall structure of the harmonic reducer, which is not compact enough, requires high positional relationship, and occupies a large space, and achieves The effect of compact structure, small moment of inertia, and smaller occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

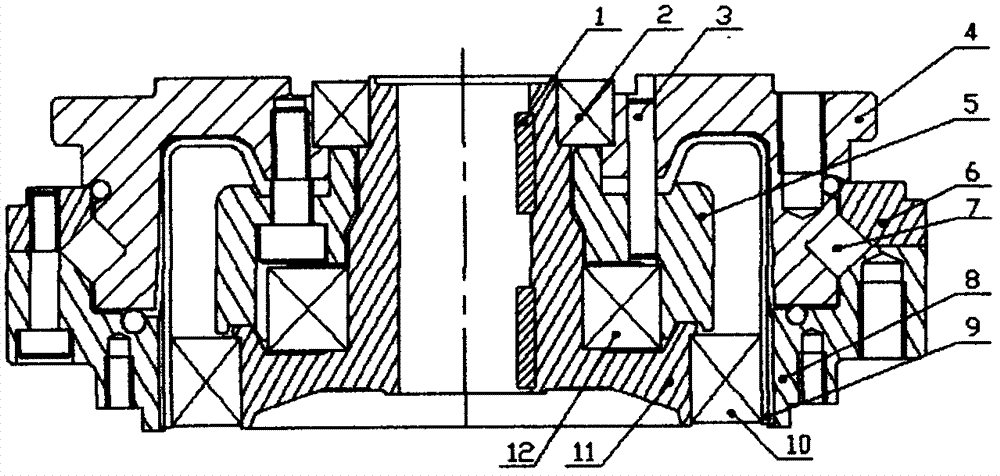

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] attached figure 1 A harmonic reducer adopts an integrated cross roller bearing structure, including key 1, bearing 2, pin 3, flex spline gland 4, support block 5, adjustment block 6, roller 7, steel wheel 8, flex spline 9. Flexible bearing 10, input shaft (wave generator) 11, bearing 12; it is characterized in that, the flexspline gland 4 is closely connected with the flexspline 9, connected with the input shaft 11 through the bearing 2, and the flexspline gland 4 The inner ring of the crossed roller bearing is composed; the steel wheel 8 and the flexspline 9 are meshed with the flexspline to transmit power through the tooth structure; the adjusting block 6 and the steel wheel 8 are composed of the outer ring of the crossed roller bearing. Adopting the integrated design feature, the flexspline gland 4 is not only the input (or output) part of the flexspline 9, but also the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com