Buried thermal insulation fixed knot

A technology for fixing joints and heat insulation layers, which is applied in the direction of protecting pipelines, heat exchange equipment, and heat preservation through heat insulation. Effect of heat loss and stable transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

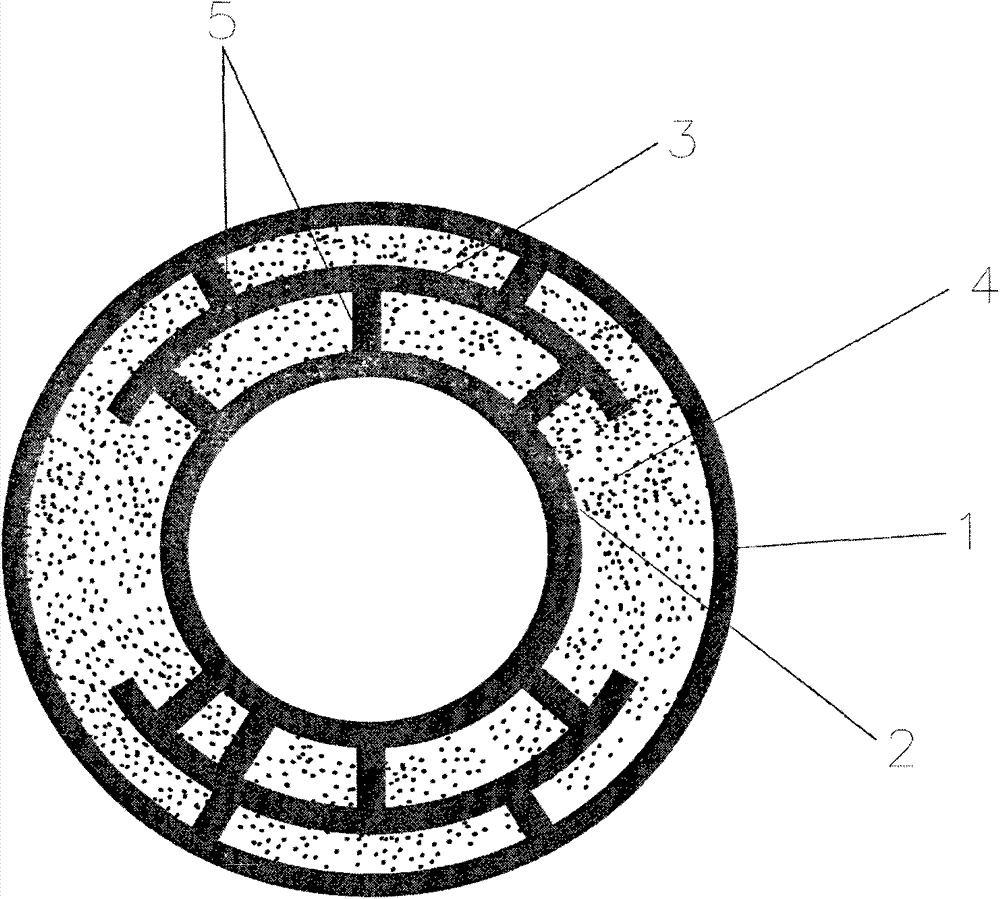

[0012] Such as figure 1 As shown, a heat-insulating fixed joint for underground burial is characterized in that: the fixed joint includes a core pipe 2, an insulating layer 5, a high-efficiency heat-insulating hard heat-insulating layer 3 and an outer pipe 1, wherein the high-efficiency heat-insulating The hard heat insulating layer 3 is arranged between the core tube 2 and the outer tube 1 and is connected with the core tube 2 and the outer tube 1 through welding points 4 , and the heat insulation layer 5 is filled between the core tube 2 and the outer tube 1 .

[0013] In the present invention, by adopting the structure in which the high-efficiency heat-insulating hard heat-insulation layer 3 is directly welded to the core pipe 2 and the outer pipe 1, the load-bearing pressure of the fixing joint is greatly improved and plays a role of fixing; the high-efficiency heat-insulation hard The heat insulating layer 3 blocks the heat transfer between the core tube 2 and the outer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com