Layered calorific value correction mode based different-coal quantity control method

A control method and coal burning technology, applied in the direction of combustion method, combustion control, fuel supply adjustment, etc., can solve the problem that the economical operation of the unit cannot be realized, and the calorific value automatic correction circuit cannot better realize the calorific value deviation from the design Value correction, unclear meaning and other issues, to achieve the effect of optimizing combustion, improving safety and economy, and improving safety and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

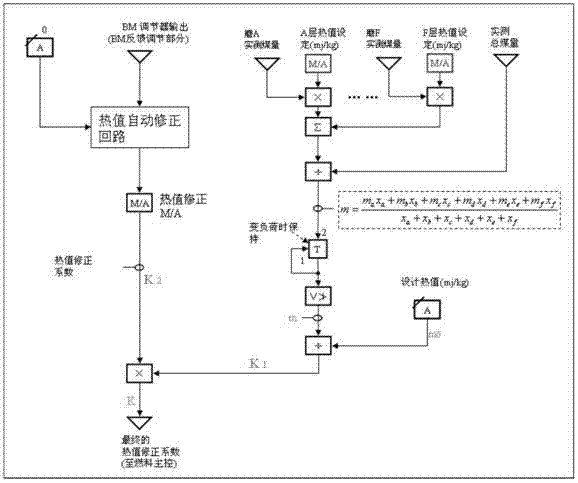

[0032] The present invention is a set of complete control methods that can effectively realize the automatic correction of the calorific value in order to deal with the mixed combustion of different coal types in the boiler, such as figure 1 shown.

[0033] Its main working principle and structure include:

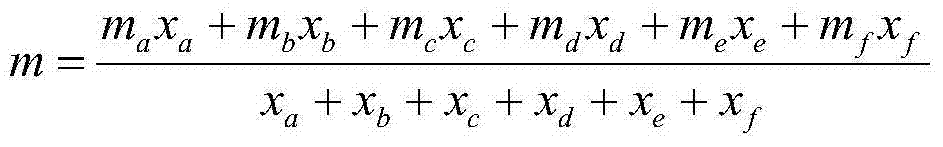

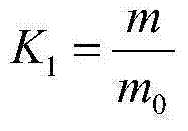

[0034] 1) Each coal seam is designed with a calorific value input module. Operators can refer to the coal quality report of the power plant and set the coal calorific value of each coal seam separately. If a certain coal seam is changed to burn other coal types, reset the new coal calorific value parameters, through the correct setting of stratified calorific values, form figure 1 The value of K1 in , basically ensures that the calorific value range is roughly correct, thus greatly reducing the correction range of the automatic calorific value correction loop, that is figure 1 The range of K2 value in the middle greatly improves the adaptability of the automatic calorifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com