Centralized temperature management system of metal cutting machine of numerical control machine tool

A technology of numerical control machine tools and management systems, applied in the direction of refrigerators, compressors, mechanical equipment, etc., can solve the problems of high failure rate of the whole machine equipment, large floor area, poor integrity of machine tools, etc., and achieve the effect of easy free combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples are used to illustrate the present invention and uses thereof, but are not intended to limit the protection scope of the present invention.

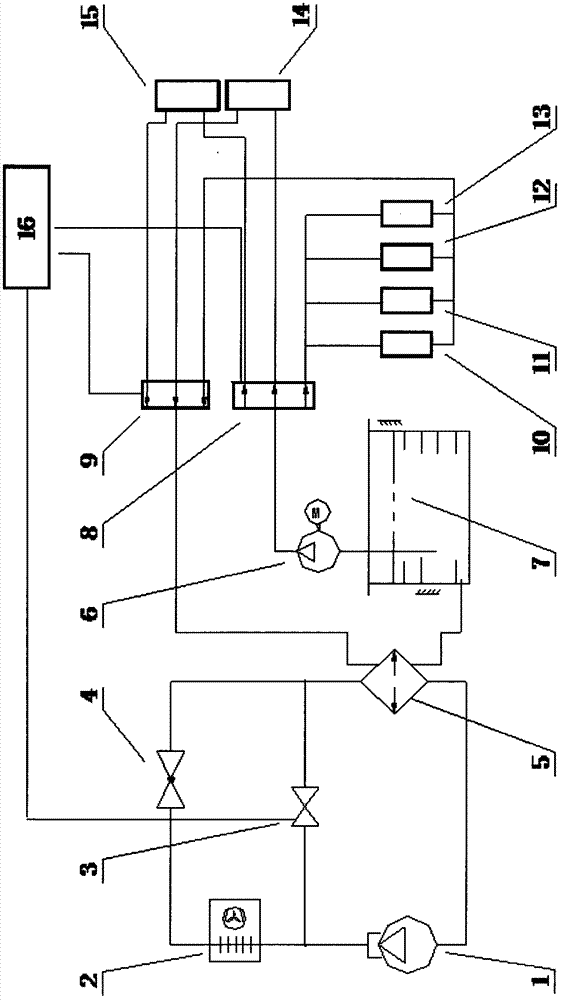

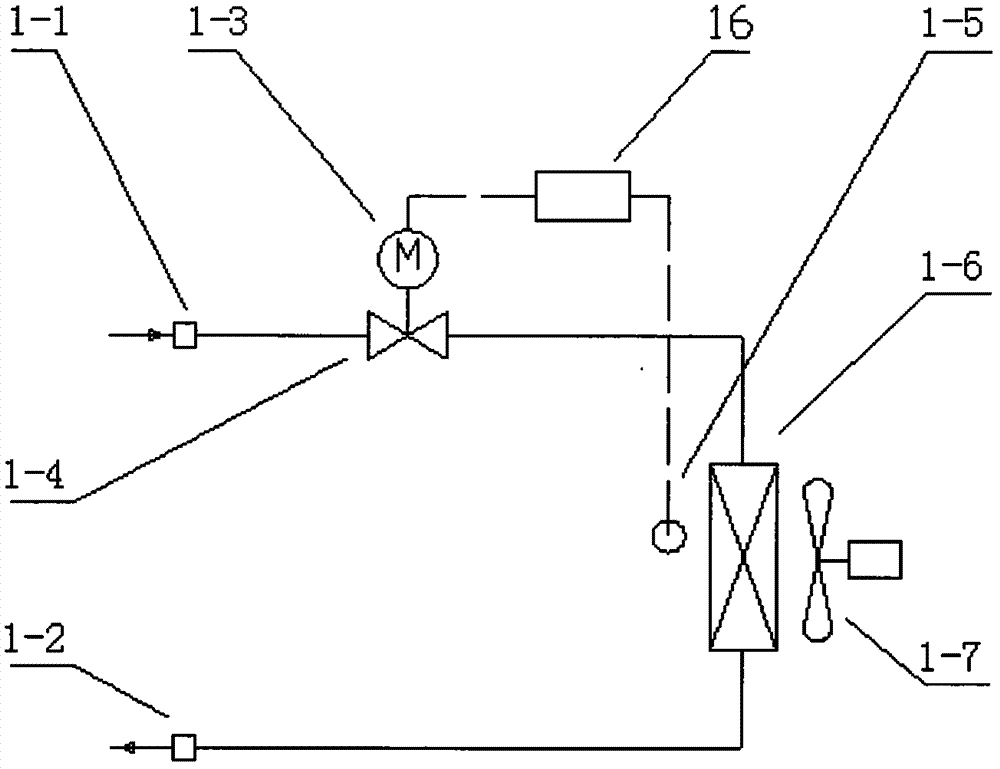

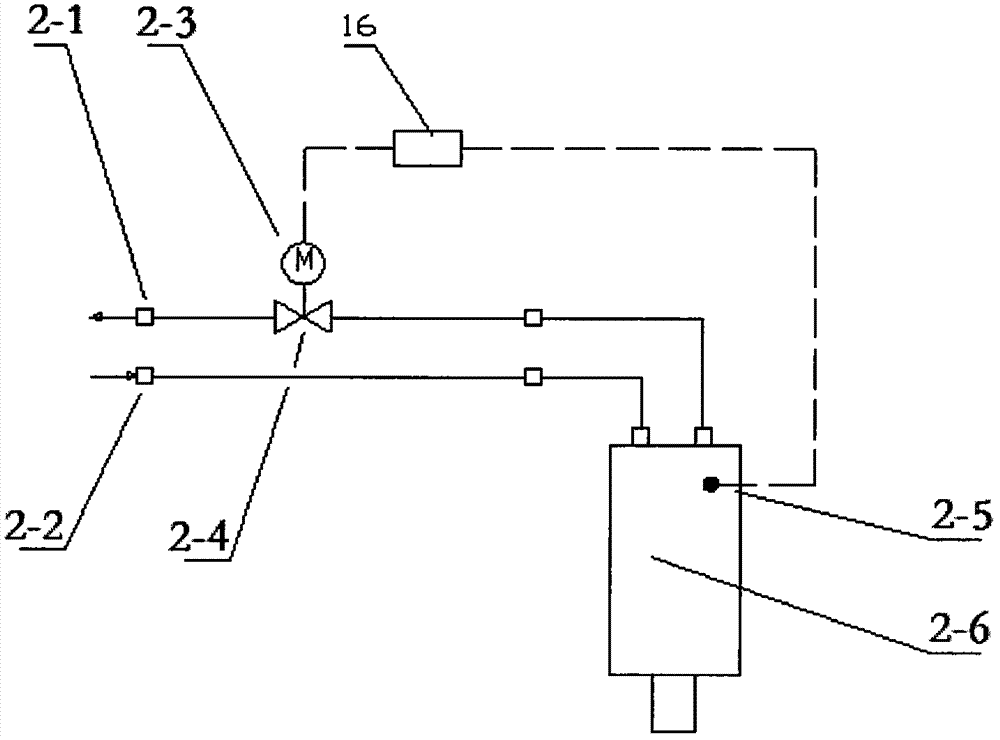

[0032] see Figure 1-7 , a centralized temperature management system for CNC machine tools and metal cutting machine tools of the present invention consists of refrigeration compressors, condensers, energy regulating valves, throttle valves, evaporators, brine pumps, brine tanks, flow distributors, It is composed of return water controller, electrical box cooling assembly, spindle cooling assembly, turntable cooling assembly, linear motor cooling assembly, hydraulic station cooling assembly, cutting fluid cooling assembly, and system controller. The distributor and the return water controller are connected, and the system controller controls the cooling capacity through the energy regulating valve to keep the temperature of the refrigerant constant. The refrigeration compressor is respectively connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com