Differential confocal aspheric surface measurement method and system of normal tracking type

A differential confocal and measurement method technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of difficult measurement and high light intensity contrast, and achieve the effect of eliminating Abbe error and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The examples of the present invention will be described in detail below in conjunction with the accompanying drawings.

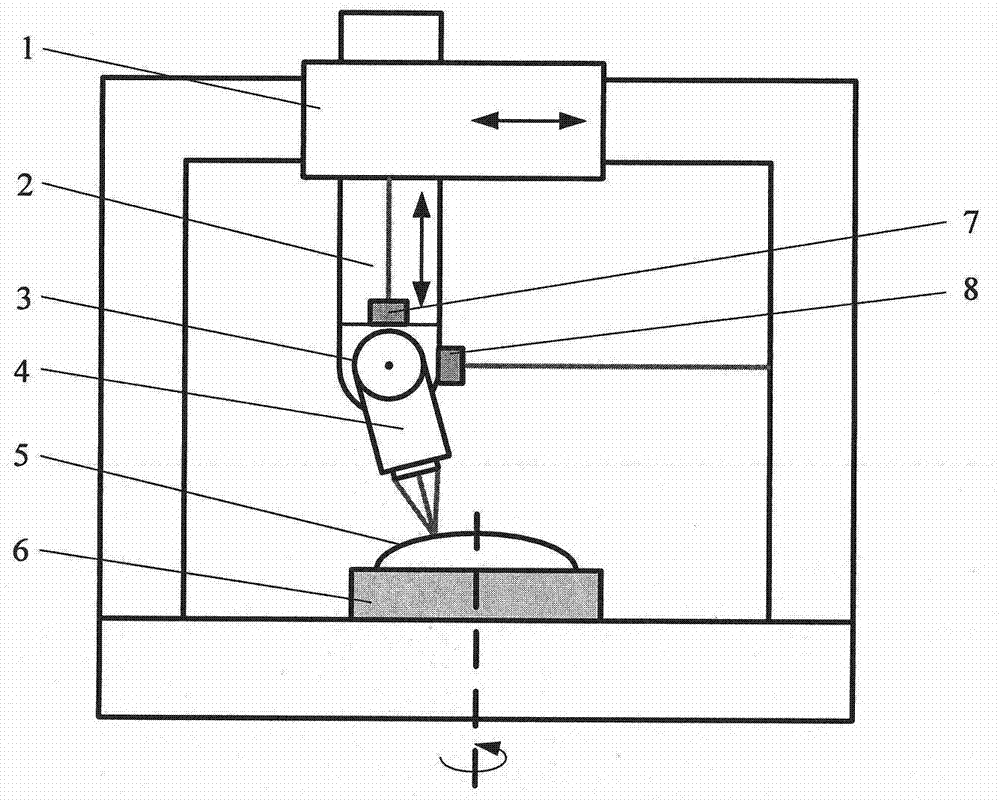

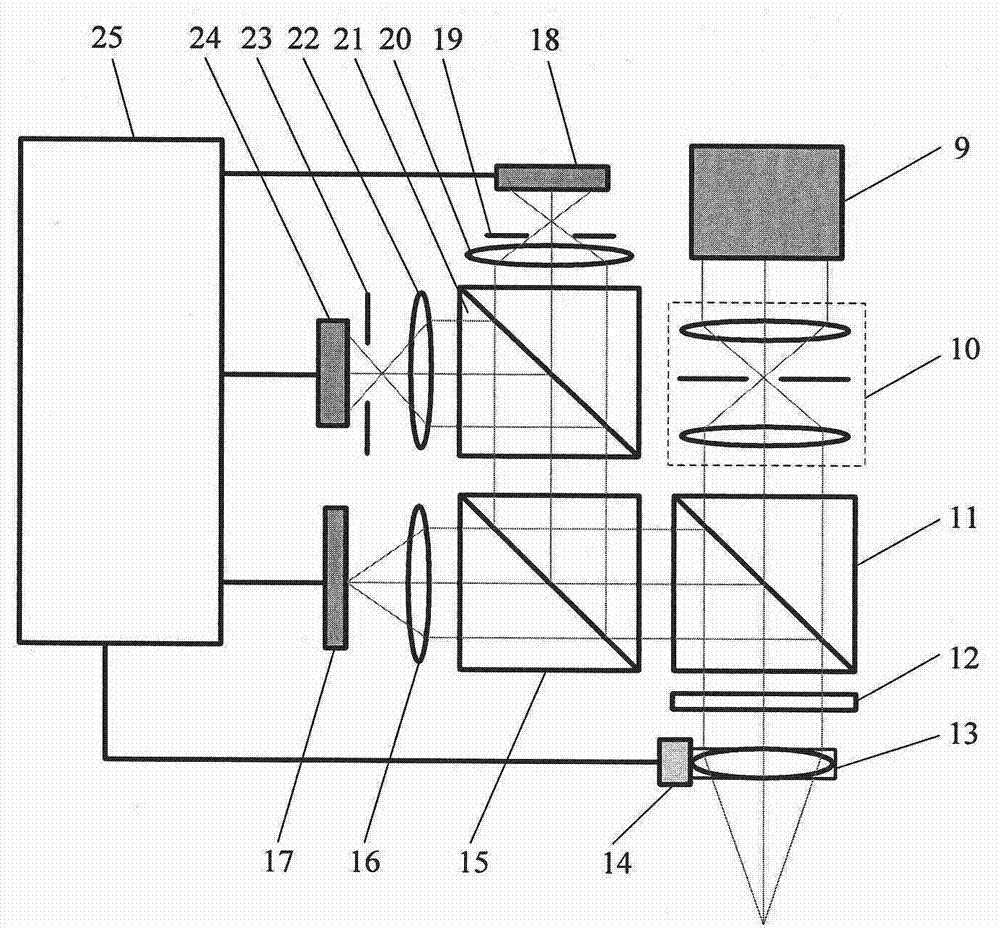

[0023]A normal tracking type differential confocal aspheric surface measurement system is characterized in that the system includes an X-guiding rail 1, a Z-guiding rail 2, a rotating mechanism 3, a differential confocal measuring head 4, an aspheric surface to be measured 5, Rotary table 6, Z-direction laser interferometer 7, X-direction laser interferometer 8; among them, X-direction rail 1 and Z-direction rail 2 are installed perpendicular to each other, which can realize scanning in the XZ plane, and the differential confocal probe 4 passes through The rotating mechanism 3 is fixed on the end of the Z guide rail 2, which can realize the rotational movement of the differential confocal probe 4, the Z direction laser interferometer 7 and the X direction laser interferometer 8 are fixed on the Z direction guide rail 2, and the Z direction laser interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com