Method for determining interlayer equivalent shear stiffness between base layer and surface layer of cement concrete pavement and horizontal shear tester

A technology of cement concrete and shear stiffness, applied in the determination of equivalent shear stiffness between cement concrete pavement base and surface layer, in the field of horizontal shear tester, can solve the problem of inability to respond to the interlayer action of wide banded structures, inability to Considering that the normal compressive stress and interlaminar shear stiffness cannot reflect the stress state of the pavement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

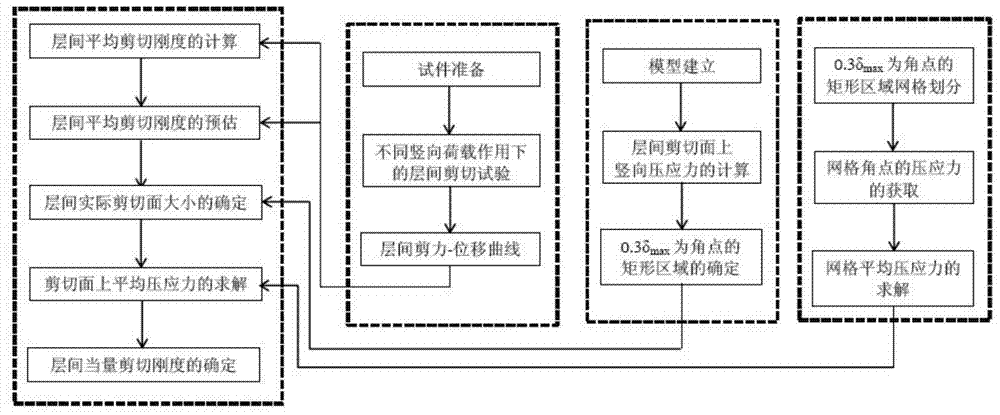

[0051] see figure 1 , the invention provides a method for determining the equivalent shear stiffness between cement concrete pavement base-surface layers, the method for determining the equivalent shear stiffness between the cement concrete pavement base-surface layers comprises the following steps:

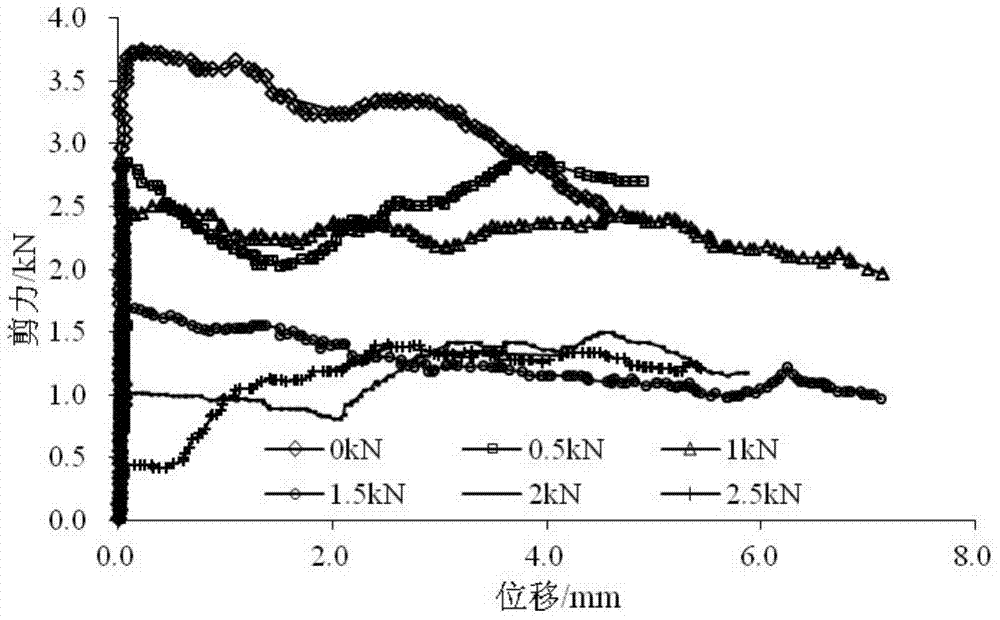

[0052] 1. Based on the Coulomb friction model, use a horizontal shear tester that can simulate vertical loads to measure the average shear stiffness between the base and surface layers of cement concrete pavement;

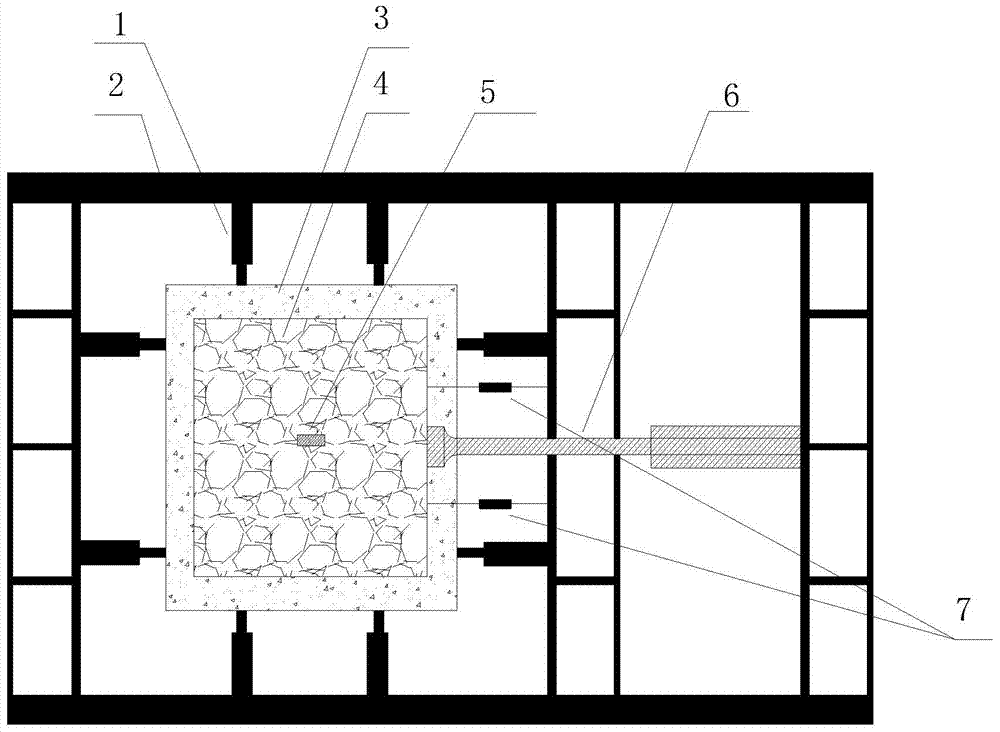

[0053] First, a cement-stabilized macadam base 3 of 70cm×70cm×20cm is formed. After the curing is completed, the interlayer (between the cement-stabilized macadam base 3 and the cement concrete surface layer 4) is treated with emulsified asphalt, and then combined as shown in Table 1. For example, pouring a 60cm×60cm×25cm cement concrete surface and curing.

[0054] Table 1 mix ratio

[0055]

[0056] Place the cement-stabilized gravel base 3 that has been cured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com