Series machine water-cooling structure

A technology of series excitation motor and cooling structure, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of poor cooling effect, inability to commutate, cooling, etc., to achieve good cooling effect, overcome large wind consumption, flow smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

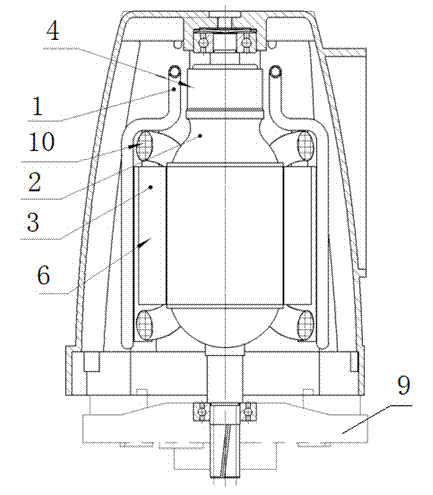

[0031] A water-cooled structure of a series motor, such as figure 1 with figure 2 As shown, the cooling pipe 1 has a circular structure from the position of the stator 3 to the position of the commutator 4, that is, the water inlet 7 of the cooling pipe 1 is set on one side of the lower end of the casing, and the cooling pipe 1 starts from the water inlet end and runs from the stator 3 The bottom is bent inward along the vertical direction of the outer surface of the stator 3, close to the lower edge of the commutator 4 from the outer surface of the stator to the top of the rotor 2, and the depth direction reaches the outer surface of the commutator 4 but does not touch the commutator. the outer surface of the commutator 4, and then go up along the vertical direction of the commutator 4 to reach the upper edge of the commutator 4, and then turn back to the bottom of the stator 3 in the same way to form a back-shaped unit, repeating this for several times After the back-shape...

Embodiment 2

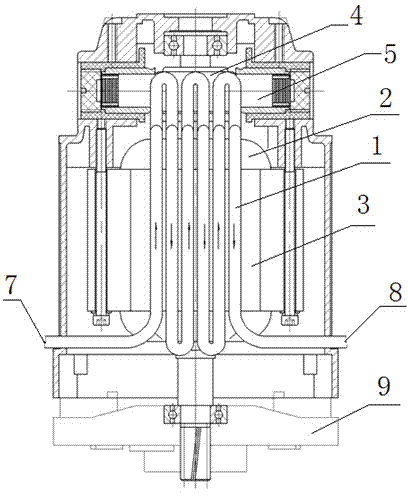

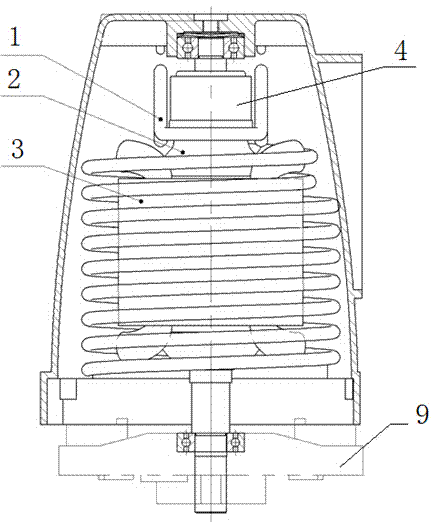

[0033] A water-cooled structure of a series motor, such as image 3 with Figure 4 As shown, the cooling pipe 1 is arranged in a spiral structure at the stator 3, and is designed as a loop structure at the two sides of the commutator position 4 parallel to the brush 5, that is, the water outlet 8 of the cooling pipe 1 is arranged in the casing On one side of the lower end, the cooling pipe 1 starts from the water inlet end and spirally coils on the outer surface of the stator 3 along the vertical direction of the outer surface of the stator 3 from the bottom of the stator 3 and close to the outer surface of the stator 3 to the lower edge of the commutator 4 Bend inward after the position, the depth direction reaches the outer surface of the commutator 4 but does not connect with the outer surface, and then goes up along the vertical direction of the commutator 4 to the upper edge of the commutator 4 and then uses the same way back to the lower edge of the commutator 4 to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com