Cooling water waste heat power generation device

A waste heat power generation and cooling water technology, applied in generators/motors, electrical components, heat exchange equipment, etc., can solve problems such as water quality decline, restricted promotion, thermal pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

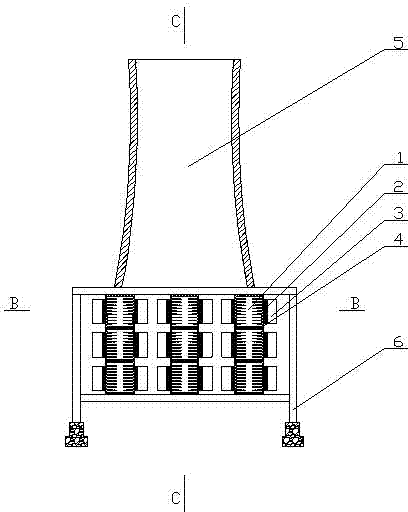

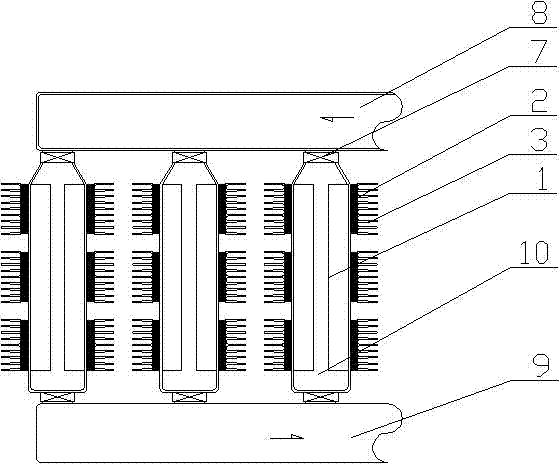

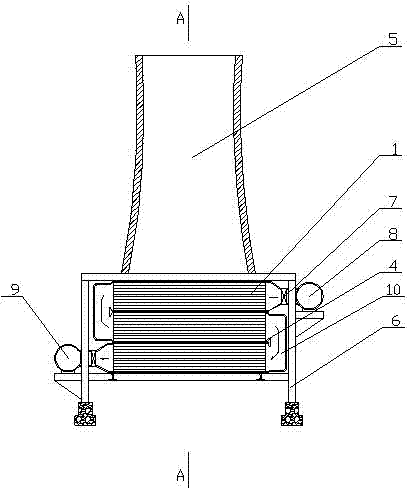

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings. The present invention mainly consists of: heat dissipation water pipe (1), power generation module (2), heat dissipation fins (3), heat dissipation air duct (5), and mounting bracket (6). It is: the installation bracket (6) is installed on the ground, the heat dissipation water pipe (1) is installed on the upper middle part, the heat dissipation fan is connected to the top, the power generation module (2) is installed on the outer surface of the heat dissipation water pipe (1), and the heat dissipation fins are vertically installed on the outside of the power generation module (2) (3); The heat dissipation water pipe (1) is made of metal, and its inner wall is provided with longitudinal fins to increase the contact area with the circulating water and increase the heat dissipation effect. ) fixed installation; the cooling water pipe (1) is twisted and stacked, with a hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com