Apparatus for foam dyeing hair

A dyeing device and foam technology, applied in the direction of washing hair or scalp device, packaging, hairbrush, etc., can solve the problems of uniform hair dyeing color, foam falling, difficult to adjust the mixing ratio, etc., to achieve excellent hair proximity , the effect of uniform dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

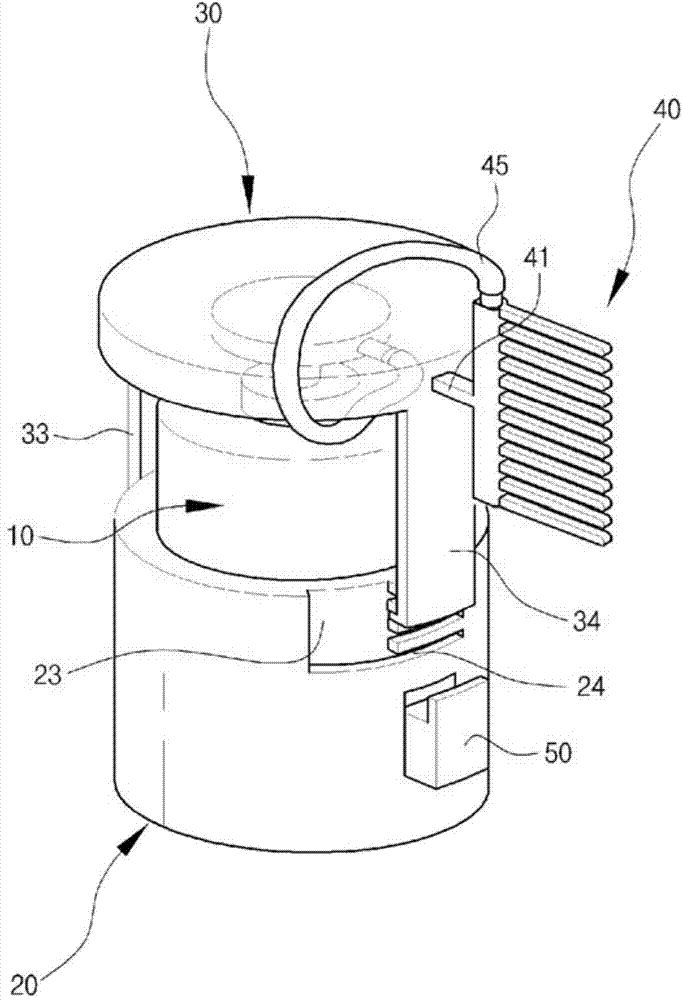

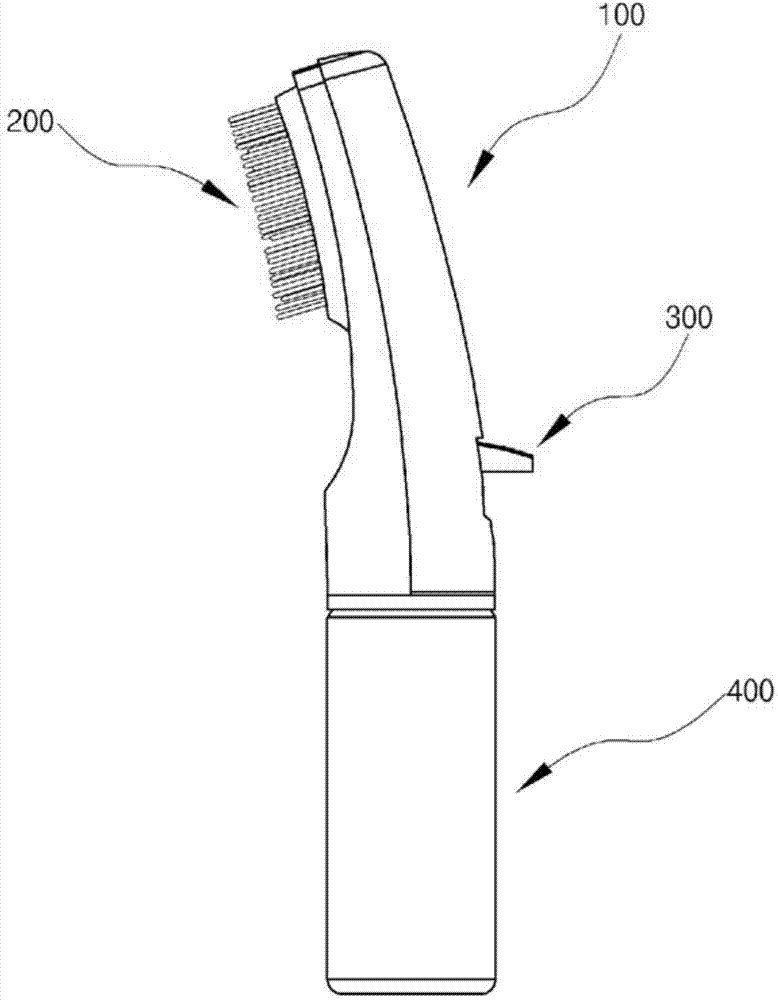

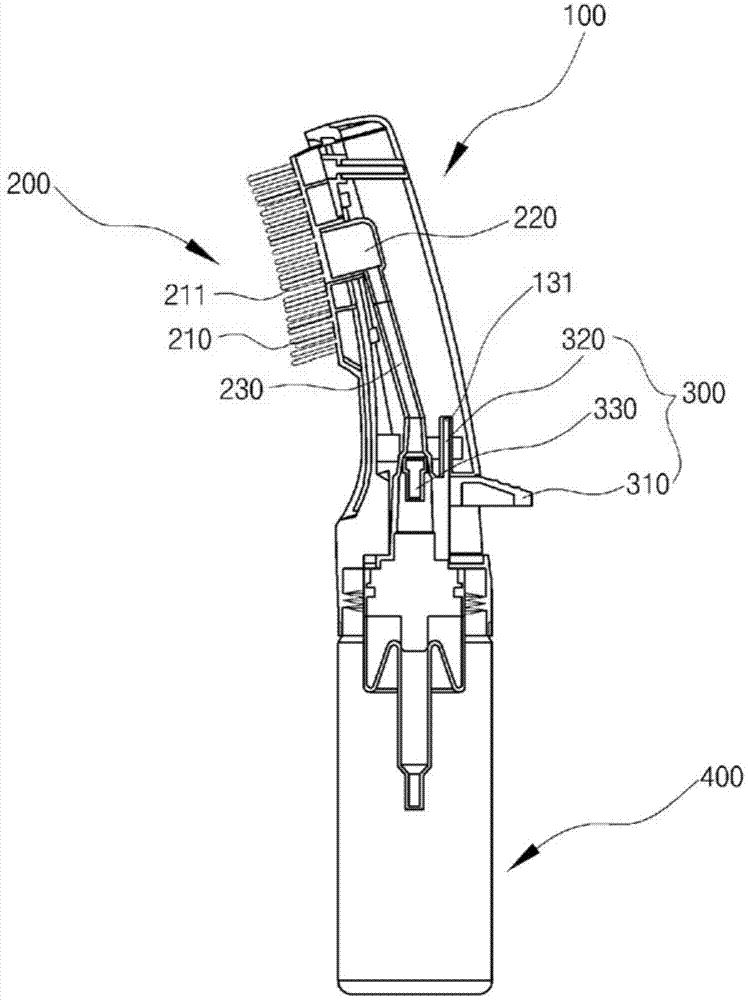

[0052] Hereinafter, preferred embodiments of the hair foam dyeing device of the present invention will be described in detail with reference to the accompanying drawings.

[0053] The hair foam dyeing device of the present invention is characterized in that it includes: a casing including a front casing and a back casing combined with the back of the front casing; Parts with a specified area are combined; the coating module is arranged in front of the above-mentioned brush part to discharge the dyeing agent; the operation part is arranged on one side of the above-mentioned housing, and the user operates the above-mentioned operation part to open the dyeing The pressure of the medicine container is used to apply the dyeing agent, and a guide part is integrally formed on the above-mentioned operation part, and the above-mentioned guide part is combined with the guide groove provided on the inner side of the above-mentioned housing to guide the operation movement range; and the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com