Discharge electrode of wet-type electrostatic precipitator and assembly stand for discharge electrode

A dust collection device and discharge electrode technology, which is applied in the field of discharge electrodes and assembly stands for discharge electrodes, can solve the problems of time-consuming and labor-intensive discharge electrodes, increased welding volume, etc., and achieve the effects of easy positioning, prevention of falling off, and easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, the present invention will be described in detail using embodiments shown in the drawings. However, unless otherwise specified, the components, types, combinations, shapes, and relative arrangements thereof described in this embodiment do not limit the scope of the present invention thereto, but are merely illustrative examples.

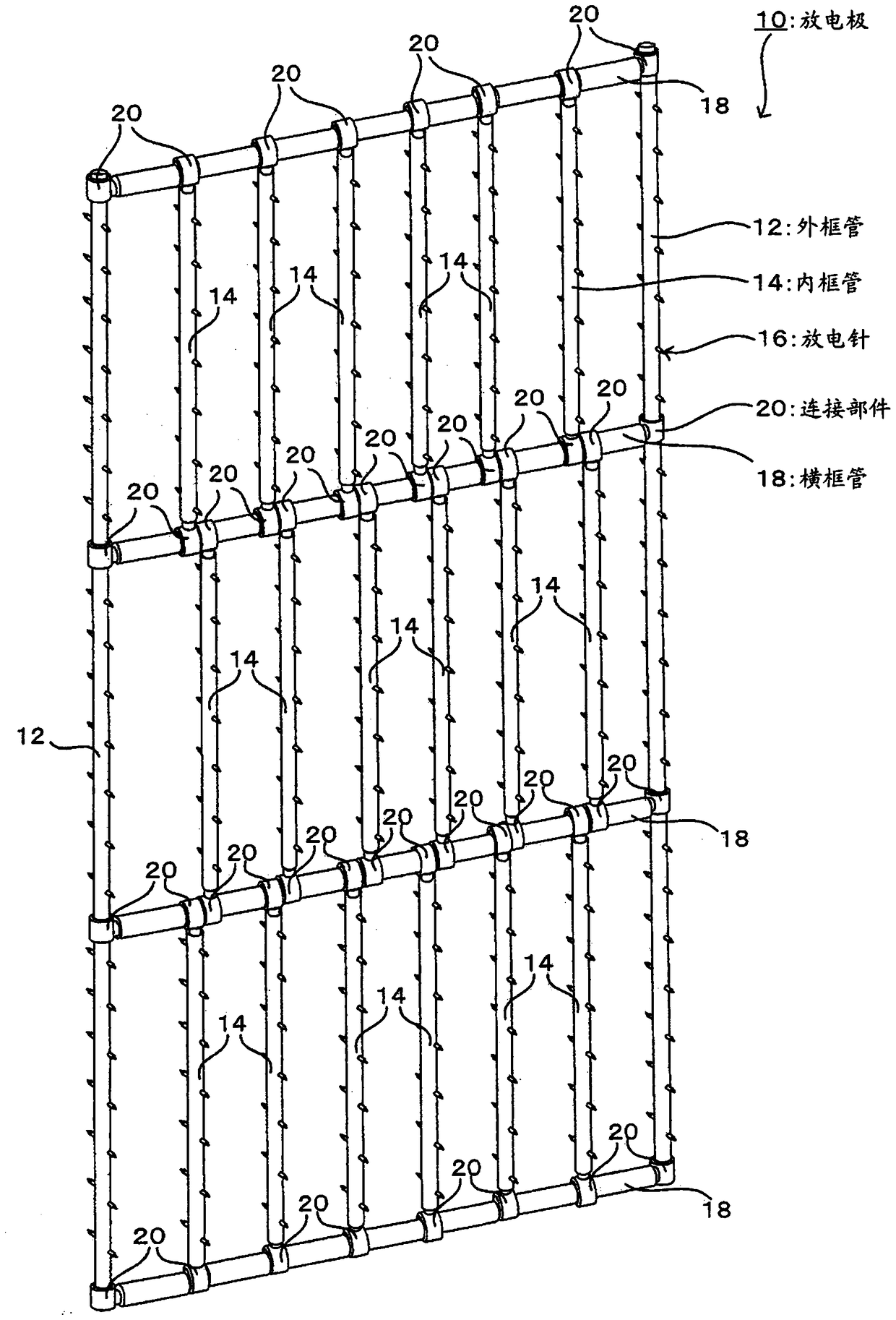

[0046] Figure 18 It is a schematic diagram (perspective view) of the discharge electrode of the wet-type electrostatic precipitator of this embodiment. The wet electrostatic precipitator 100 using the discharge electrode of this embodiment has an overall external shape by the casing 102 that accommodates the discharge electrode 10 and the dust collecting plate 108 . Furthermore, the housing 102 has an inlet 104 for introducing exhaust gas, and an outlet 106 for discharging the exhaust gas after collecting dust particles. In the casing 102 , the main surfaces of the discharge electrode 10 and the dust collecting plate 108 face e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com