Heavy type intelligent environmental-friendly grain moving and purifying system

A purification system and intelligent technology, applied in chemical instruments and methods, solid separation, smoke and dust removal, etc., can solve problems such as the inability to meet large processing capacity and efficient environmental cleaning, efficient dust removal, efficient intelligence, and efficient recycling, etc., to achieve control. The frequency of occupational pneumoconiosis, the effect of improving economic and social benefits, and promoting product market share

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

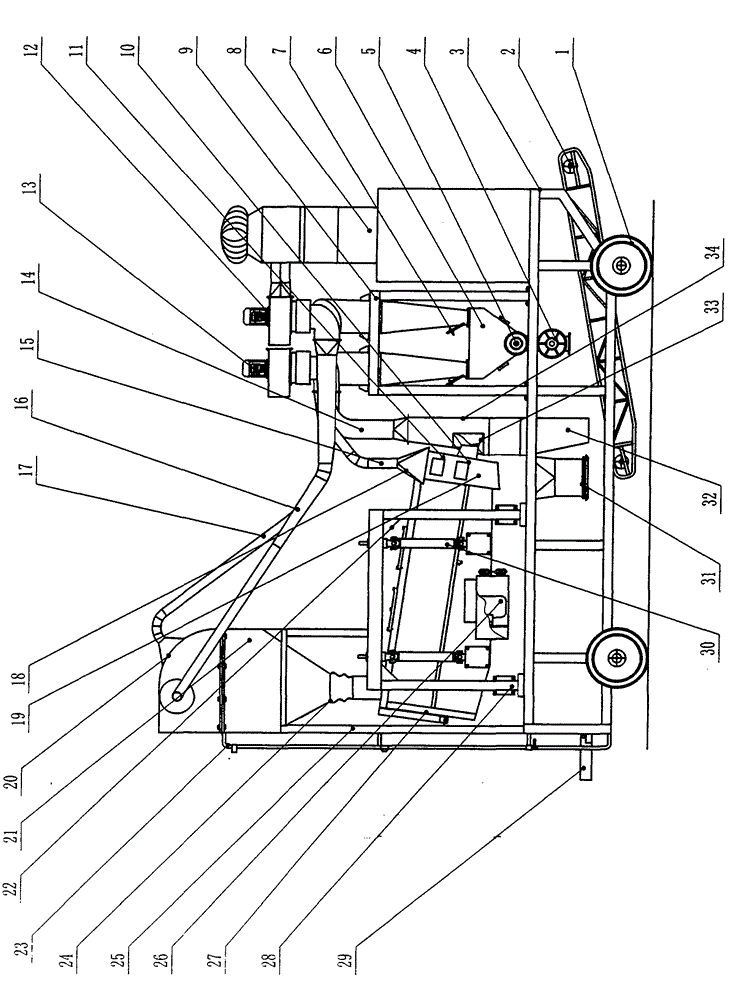

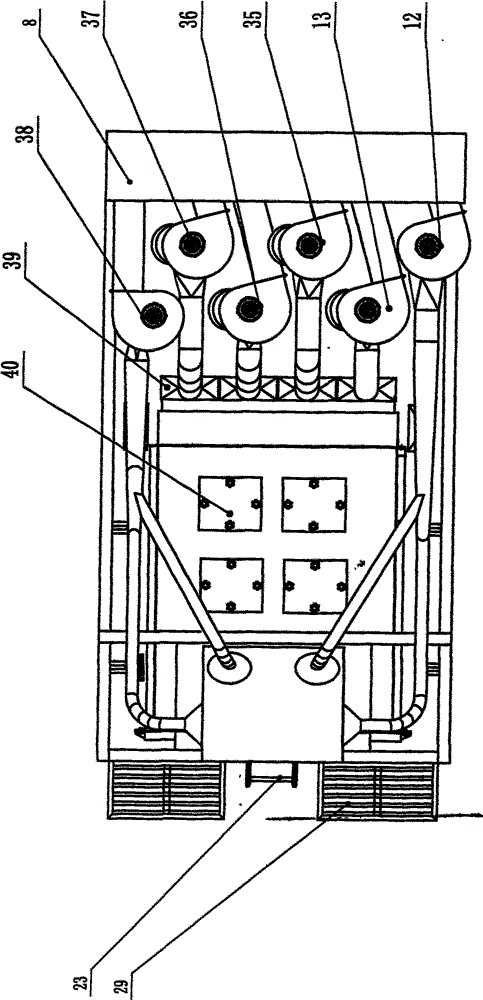

[0023] The products involved in this project are as follows: figure 1 , 2 As shown, the feed hopper 21 is arranged on the front end of the top of the walking chassis 3 through the feed support frame 25, and the dust cover 20 is arranged on the top of the feed hopper 21 and is connected by bolts; the inside of the feed hopper 21 is provided with a fence, a uniform device, the fence is arranged above the leveling device; the bottom of the feed hopper 21 is connected with the feeding port of the screening device through a square hose 24. The side of the dust cover 20 is provided with a feed inlet, and the opposite side of the feed inlet is provided with 2 No. 1 dust suction branch pipes 17; Link to each other with multiple suction pipes 16 respectively. The multi-element dust suction pipe 16 is connected with the air inlets of No. 1 dust remover 12 and No. 2 dust remover 38 . The screen body 27 is arranged below the screening support frame 28 by 4 pieces of universal suspensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com