Composite plate and production method thereof

A production method and composite board technology, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve problems such as edge lifting, interface non-bonding, cladding board breakdown, etc., to reduce consumption and production The effect of less investment and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

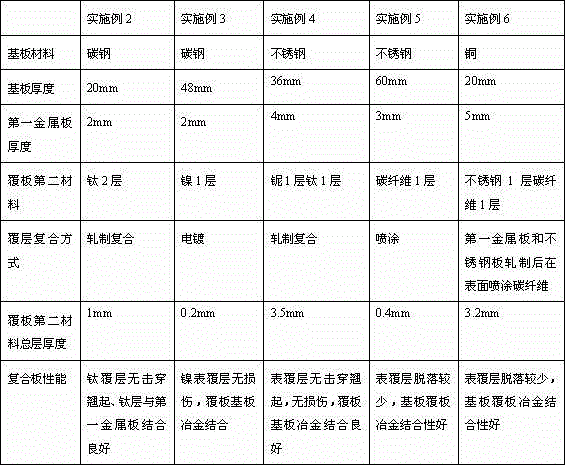

Examples

Embodiment 1

[0016] A method for producing a composite plate, comprising the following steps: 1) selecting two metal plates of the first metal material, the first metal plate and the second metal plate, wherein the first metal material is selected from one of stainless steel, carbon steel, copper, and aluminum kind. The first metal plate is used to prepare the cladding plate, and the second metal plate is used as the substrate; II) the cladding plate is prepared, and the cladding plate is formed by rolling compound, spraying or electroplating on one side of the first metal plate. Composite at least one layer of second material to make the cladding plate; the second material is selected from nickel, titanium, tantalum, niobium, zirconium, stainless steel, copper, aluminum, or one of the above metal alloys and carbon fiber. The thickness of each layer of the second material is less than 2mm. III) The cladding plate and the base plate are explosively welded to form a composite plate, wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com