Processing equipment and method for flame retarding modification of blend fiber felt

A technology for blending fibers and processing equipment, which is applied in textile and papermaking, textile material processing, and textile material drum processing. The effect of uniform dispersion of fuel dosage, small amount of flame retardant and high flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

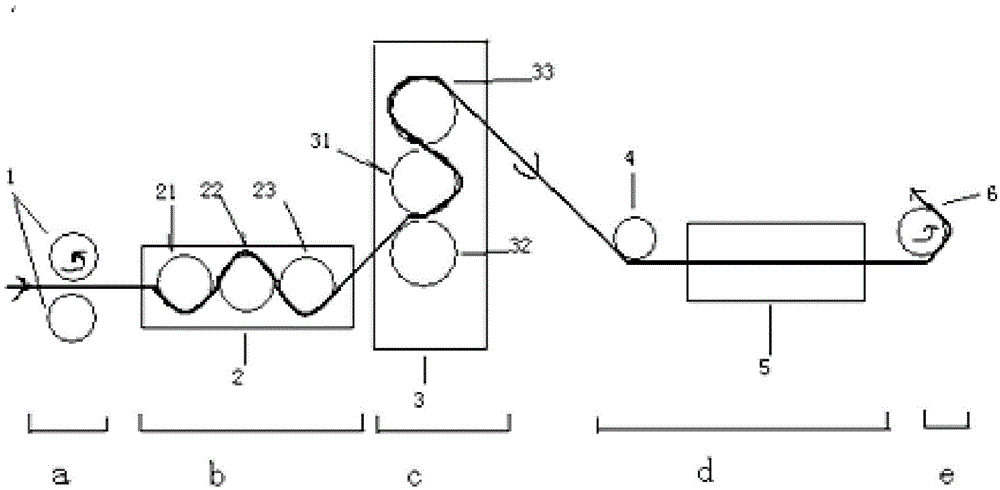

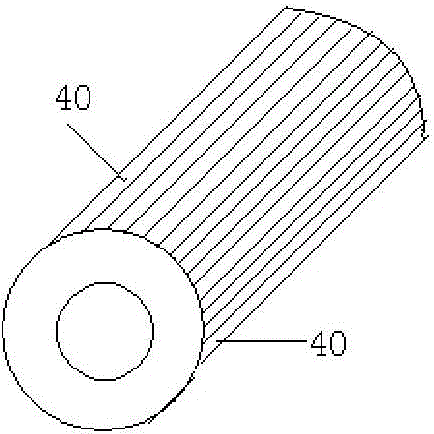

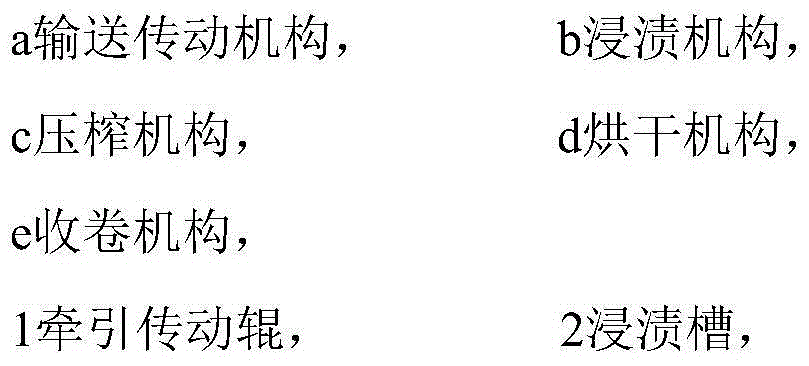

[0041] Such as figure 1 As shown, a kind of flame retardant modification processing equipment for blended fiber felt, which includes a transmission transmission mechanism a, an impregnation mechanism b, a pressing mechanism c, a drying mechanism d, and a winding mechanism e from front to back, wherein the transmission transmission mechanism a , dipping mechanism b, pressing mechanism c, drying mechanism d and winding mechanism e are connected in sequence; dipping mechanism b is composed of dipping tank 2 and three dipping rollers 21, 22, 23, and squeezing mechanism c is composed of recovery tank 3 and three Squeeze rolls 31, 32, and 33 are combined calender rolls, and drying mechanism d is made up of tension roll 4 and oven 5.

[0042] Conveyor transmission mechanism a adopts a pair of traction drive rollers 1, which are composed of upper and lower rollers, in which the lower roller is stationary and the upper roller rotates counterclockwise to drive the material blended fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com