Wear-resistant and ravel-resistant knitted fabric curing agent, preparation method and use method

A knitted fabric and curing agent technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of uneven surface of knitted fabrics, easy to be worn, easy to deform, etc., and achieve long-term appearance maintenance, high shape stability, and anti-fuzzing. The effect of improving the detachment resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the present invention,

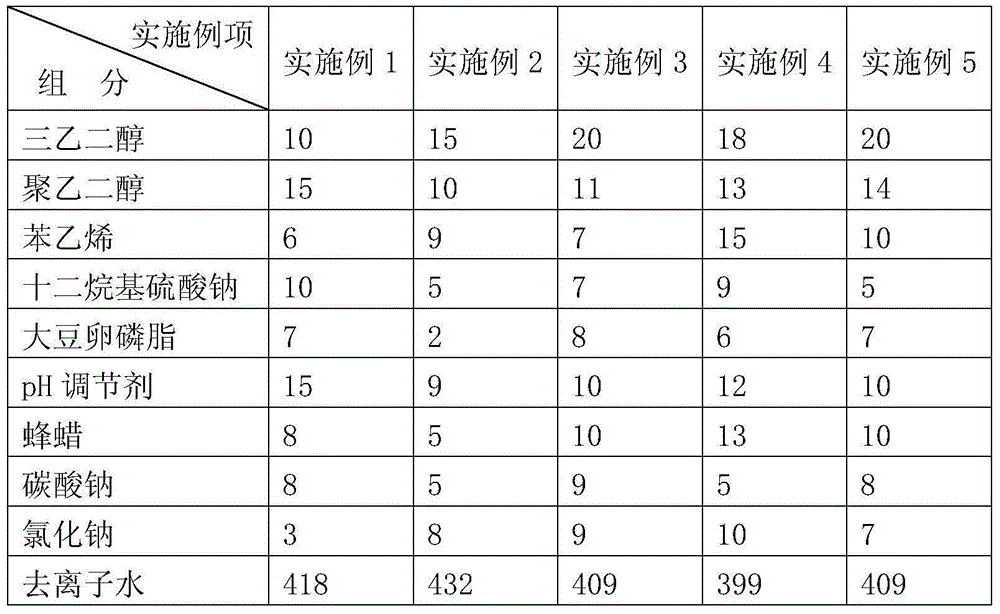

[0017] The components in Examples 1-5 are shown in the following table: (unit: grams)

[0018]

[0019] Preparation:

[0020] Stir triethylene glycol, polyethylene glycol, styrene, sodium lauryl sulfate, soybean lecithin until completely dissolved and mixed;

[0021] 2) then add pH regulator to adjust to 5, sodium carbonate, sodium chloride in turn, fully stir for 20-30min;

[0022] 3) Put the above mixture into the reaction kettle, add beeswax, control the temperature at 40-60°C, rotate the speed at 500-1000 rpm, then add deionized water, and reduce to normal temperature.

[0023] Instructions:

[0024] 1) Put the wear-resistant and anti-shedding knitted fabric curing agent into a closed spray bottle at high pressure, spray evenly on the surface of the knitted fabric, especially the cross-section layer, then dry the knitted fabric at 70-90 ℃, and then at 150- Heat setting at 160°C;

[0025] 2) Wash the heat-setting knitted fabric for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com